- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

15000 kg

-

Name:

-

lithium ion battery recycling machine

-

Feeding Material:

-

Waste batteries

-

Final Products:

-

Aluminum, copper, plastic, black powder,etc.

-

Voltage:

-

220V/380V/415V/440V/customized

-

Application:

-

Waste battery recycling

-

Certification:

-

CE

-

Delivery time:

-

20~45 days

-

Customized:

-

Available

Quick Details

-

Production Capacity:

-

300-2000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gomine

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

15000 kg

-

Name:

-

lithium ion battery recycling machine

-

Feeding Material:

-

Waste batteries

-

Final Products:

-

Aluminum, copper, plastic, black powder,etc.

-

Voltage:

-

220V/380V/415V/440V/customized

-

Application:

-

Waste battery recycling

-

Certification:

-

CE

-

Delivery time:

-

20~45 days

-

Customized:

-

Available

Products Description

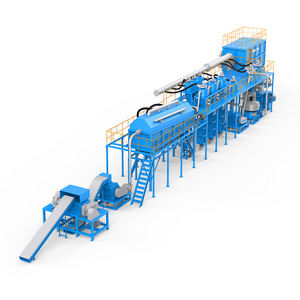

Soft And Hard Shell Car Battery Recycling Plant Machine Cost Lithium Ion Battery Recycling Machine

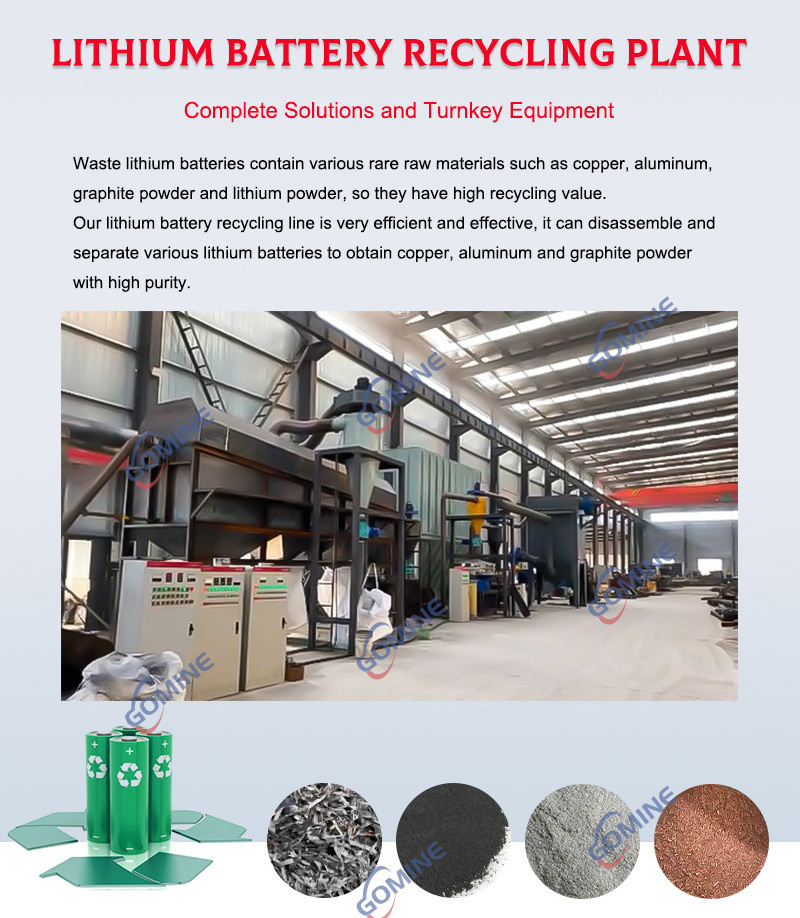

Lithium battery recycling provides essential raw materials for manufacturing new batteries while lessening dependence on finite resources, fostering sustainable development.

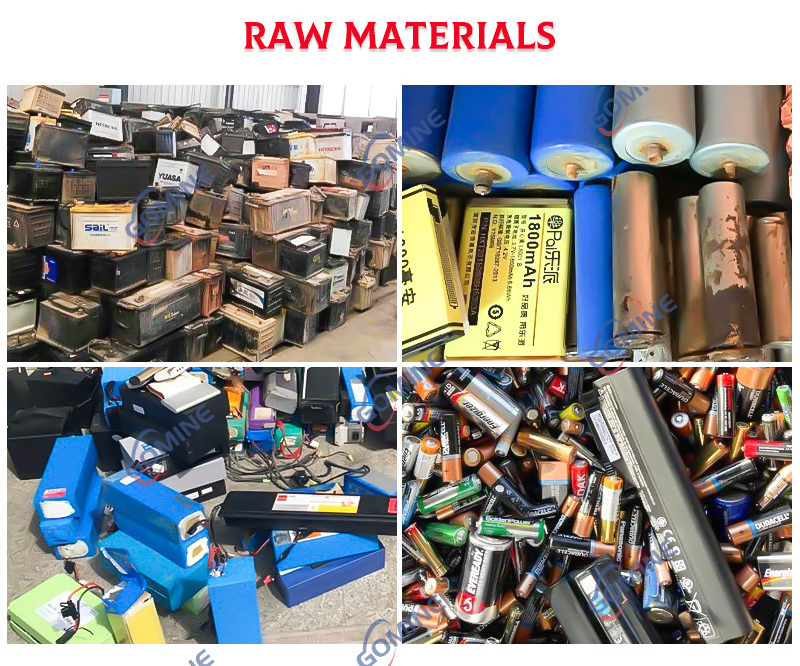

Lithium batteries contain several valuable materials worth recycling, inculding: Lithium(primary component of lithium batteries), Cobalt, Nickel(provide high energy density), Aluminum (the casing of lithium batteries is typically made of aluminum), Manganese(used to enhance battery performance and stability), Copper(connectors and wires in lithium batteries are often made of copper), Plastics and other components.

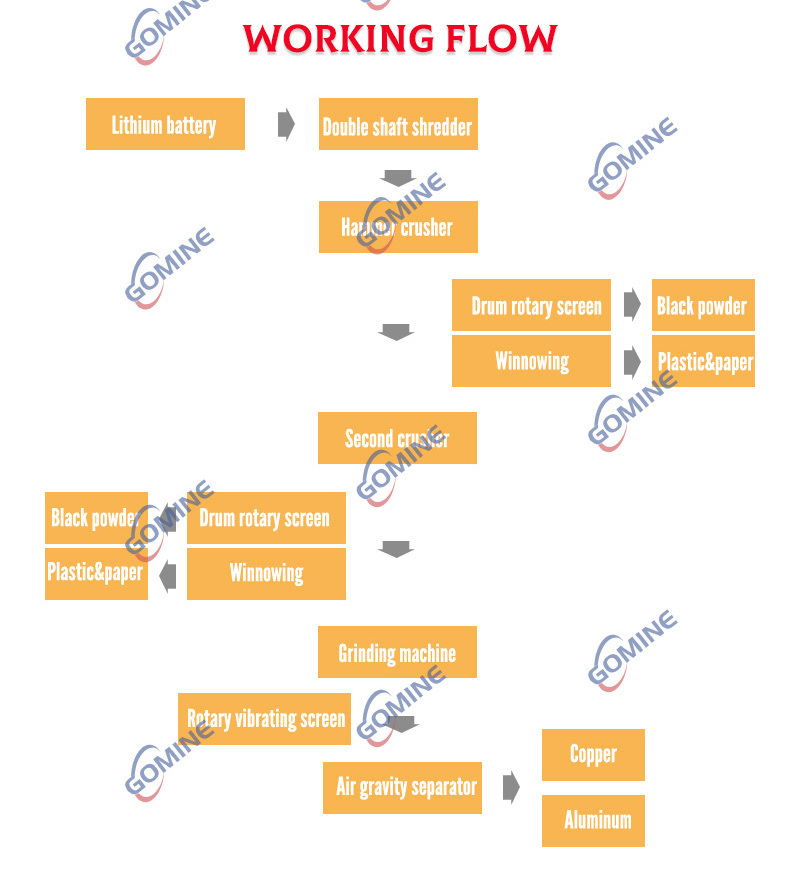

The lithium battery recycling plant consists of multiple machines working together, the following is a description of some of the core equipment:

Shredder:

Shredded lithium batteries into smaller pieces.

Hammer crusher:

For the secondary crushing of shredded materials.

Grinder:

For the grinding of the crushed materials.

Separation Machine:

Separate the materials after being ground.

Collector:

Collect and release the dust .

Pulse Purifier (Air Cleaner):

Clean all the dust produced during the operation of the wholesystem.

Classifying Screen:

Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic Machine:

Separate nickel from the metals.

Gravity Separator:

Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower:

Keep the whole system in a negative state so as to collect the materialsand purity the air .

|

Model

|

Capacity

|

|

GML-300

|

300kg/h

|

|

GML-500

|

500kg/h

|

|

GML-800

|

800kg/h

|

|

GML-1000

|

1000kg/h

|

|

GML-1500

|

1500kg/h

|

|

GML-2000

|

200kg/h

|

Note:

1. The above lithium-ion battery recycling equipment is our standard configuration. For different raw materials, the configuration might be different.

2. Please feel free to contact us for detailed information or special request.

Packaging & Shipping

Hot Searches