- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

FillinMachine

-

Dimension(L*W*H):

-

600*400*800mm

-

Weight:

-

80 KG

-

Product name:

-

Vertical horizontal screw powder filling machine

-

Keywords:

-

Vial Powder Filling Machine

-

Capacity:

-

10-30 times/min

-

Range of measurement:

-

0.1g-100g (filling parts need to be replaced)

-

Volume:

-

20L

-

Measuring method:

-

Screw metering

-

Suitable for bottle height:

-

50-200(mm)

-

Suitable for bottle diameter:

-

15-100(mm)

-

Products applicable:

-

Various Powder

-

Operation system:

-

Touch screen+Pedal

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

FillinMachine

-

Dimension(L*W*H):

-

600*400*800mm

-

Weight:

-

80 KG

-

Product name:

-

Vertical horizontal screw powder filling machine

-

Keywords:

-

Vial Powder Filling Machine

-

Capacity:

-

10-30 times/min

-

Range of measurement:

-

0.1g-100g (filling parts need to be replaced)

-

Volume:

-

20L

-

Measuring method:

-

Screw metering

-

Suitable for bottle height:

-

50-200(mm)

-

Suitable for bottle diameter:

-

15-100(mm)

-

Products applicable:

-

Various Powder

-

Operation system:

-

Touch screen+Pedal

Marketing Campaign

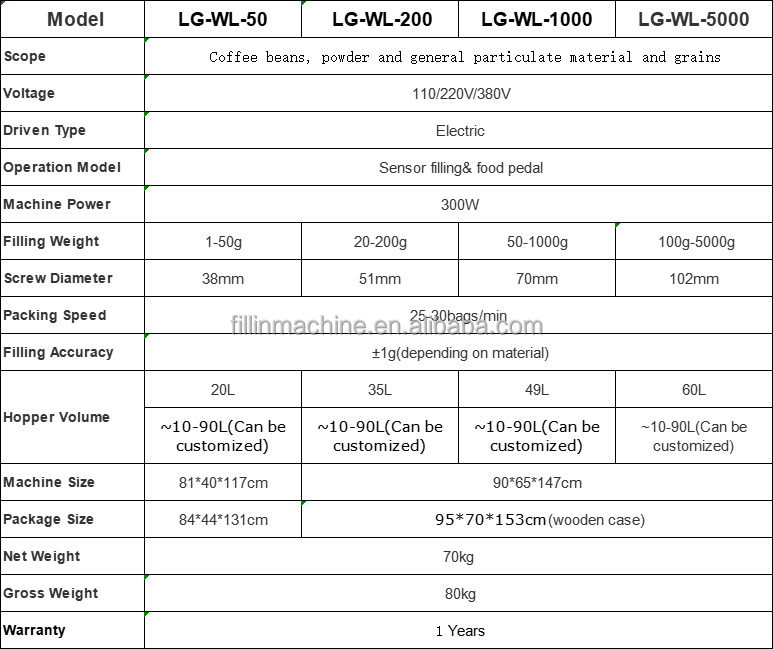

Specification

|

item

|

value

|

|

Condition

|

New

|

|

Type

|

Filling Machine

|

|

Brand Name

|

FillinMachine

|

|

Product name

|

Vertical Dry Powder Weighing Filling Machine Auger Powder Filler Dispenser Spiral Screw Powder Filling Machine

|

|

Keywords

|

Vial Powder Filling Machine

|

|

Capacity

|

10-30 times/min

|

|

Range of measurement

|

1g-100g (filling parts need to be replaced)

|

|

Volume

|

20L(customized)

|

|

Measuring method

|

Screw metering

|

|

Suitable for bottle height

|

50-200(mm)

|

|

Suitable for bottle diameter

|

15-100(mm)

|

|

Products applicable

|

Various Powder

|

|

Operation system

|

Touch screen+Pedal

|

Recommend Products

Products Description

The semi automatic Vial Powder filling Machine introductions:

Vertical Dry Powder Weighing Filling Machine Auger Powder Filler Dispenser Spiral Screw Powder Filling Machine

Adopting PLC control, it has the advantages of high accuracy, fast speed, large torque and long life. Touch screnn display, the packing weight can be adjusted steplessly at any time, the working status can be changed at any time, and the operation is convenient.

This semi automatic powder filling machine can complete tasks such as weighing and filling. Suitable for packaging powdery and granular materials that are easy to flow or have poor fluidity;

Filling Machine Features:

1. This powder filling machine is integrated with machine, electricity, light and instrument. It is controlled by single chip

computer. It has the functions of automatic quantification, automatic filling, automatic adjustment of measurement error and so on.( Optional servo motor ) 2. Stepping motor and electronic weighing technology, fast speed and high precision.

3. The same quantitative packaging machine can be packed 0.1-100g by adjusting and replacing filling parts of different specifications with the keyboard of electronic scale.

4. Errors caused by material specific gravity and material level change can be automatically tracked and corrected.

computer. It has the functions of automatic quantification, automatic filling, automatic adjustment of measurement error and so on.( Optional servo motor ) 2. Stepping motor and electronic weighing technology, fast speed and high precision.

3. The same quantitative packaging machine can be packed 0.1-100g by adjusting and replacing filling parts of different specifications with the keyboard of electronic scale.

4. Errors caused by material specific gravity and material level change can be automatically tracked and corrected.

Buyer Evaluation

Our services

1. If there is a machine problem within 1 year of delivery,we can provide free spare parts replacement

2. Support returns within 2 days after payment,and cannot be returned after delivery.

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested.

6. Support Certifications,CE certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes.

2. Support returns within 2 days after payment,and cannot be returned after delivery.

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested.

6. Support Certifications,CE certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes.

Details Images

Hot Searches