- Product Details

- {{item.text}}

Quick Details

-

Size:

-

3300mmx2114mmx1750mm

-

Power:

-

4.5Kw, 4.5Kw

-

Weight (KG):

-

2500 kg

-

Product name:

-

Sludge Dewatering Screw Press Machine

-

Application:

-

Wastewater Treatment Plant

-

Type:

-

Screw Press

-

Capacity:

-

120-200kg/ds/h

-

Material:

-

304 Sainless Steel

-

Certification:

-

ISO9001:2008

-

Voltage:

-

220v 380V 50HZ 60HZ(Or Customized

-

Control:

-

Automatic Control Box

-

After-sales Service:

-

Video Techinical Support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

longdai

-

Weight:

-

2500kg

-

Size:

-

3300mmx2114mmx1750mm

-

Power:

-

4.5Kw, 4.5Kw

-

Weight (KG):

-

2500 kg

-

Product name:

-

Sludge Dewatering Screw Press Machine

-

Application:

-

Wastewater Treatment Plant

-

Type:

-

Screw Press

-

Capacity:

-

120-200kg/ds/h

-

Material:

-

304 Sainless Steel

-

Certification:

-

ISO9001:2008

-

Voltage:

-

220v 380V 50HZ 60HZ(Or Customized

-

Control:

-

Automatic Control Box

-

After-sales Service:

-

Video Techinical Support

Product Description

The main body of the screw-type sludge dewatering machine is composed of multiple fixed rings, a moving ring and a spiral filter part, which organically combines the filtration concentration technology and the pressing technology, and completes the sludge concentration and pressing and dehydration in one cylinder; In the cavity, it uses the relative swimming between the fixed and movable laminations to quickly discharge the filtrate and never block it; in the dehydration cavity, the continuous shrinkage of the volume in the spiral cavity is used to enhance the internal pressure and the pressure regulation mechanism of the back pressure plate, so that the The unique and subtle filter body mode replaces the traditional filter cloth and centrifugal filtering methods, and its advanced solid-liquid separation and self- cleaning technology will create a new era of sludge dewatering.

Working Principle

1.Concentration: When the screw push shaft rotates, the multiple fixed and movable laminations located on the periphery of the push shaft move relatively. Under the action of gravity, the water is filtered out from the relatively moving lamination gap to achieve rapid concentration.

2.Dewatering: the concentrated sludge moves forward with the rotation of the screw shaft; along the outlet direction of the mud cake, the pitch of the screw shaft gradually decreases, the gap between the rings also gradually decreases, and the volume of the spiral cavity gradually decreases. Continuously shrinking; under the action of the back pressure plate at the outlet, the internal pressure gradually increases, and under the continuous operation of the screw shaft, the water in the sludge is squeezed and discharged, and the solid content of the filter cake is continuously increased, and finally the sludge is realized. continuous dehydration.

3. Self-cleaning: The rotation of the screw shaft drives the moving ring to rotate continuously, and the equipment relies on the movement between the fixed ring and the moving ring to realize the continuous self-cleaning process, thus cleverly avoiding the common clogging problem of traditional dehydrators.

Parameters

|

Specification///model

|

|

DL-101

|

DL-102

|

DL-201

|

DL-202

|

DL-301

|

DL-302

|

||||||

|

Processing capacity(m³/h)

|

Mud concentration(S.S.0.2-0.5%)

|

0.6-1.5

|

1.2-3.0

|

1.8-4.5

|

3.6-9.0

|

6.0-15

|

12-30

|

||||||

|

|

Mud concentration(S.S.0.5-2.0%)

|

0.25-0.6

|

0.5-1.2

|

0.75-1.8

|

1.5-3.6

|

2.5-6.0

|

5.0-12

|

||||||

|

|

Mud concentration(S.S.2.0-5.0%)

|

0.1-0.25

|

0.2-0.5

|

0.3-0.75

|

0.6-1.5

|

1.0-2.5

|

2.0-5.0

|

||||||

|

|

Mud concentration(S.S.0.2-0.5%)

|

0-3.0

|

2.4-6.0

|

3.6-9.0

|

7.2-18

|

12-30

|

24-60

|

||||||

|

|

Mud concentration(S.S.0.5-2.0%)

|

0-5.0

|

5.0-10

|

9.0-15

|

18-30

|

30-50

|

50-100

|

||||||

|

|

Mud concentration(S.S.2.0-5.0%)

|

0-5.0

|

5.0-10

|

9.0-15

|

18-30

|

30-50

|

50-100

|

||||||

|

Mud cake moisture content(%)

|

|

75-85

|

|

|

|

|

|

||||||

|

Spiral diameter (mm) * quantity (pieces)

|

|

100*1

|

100*2

|

200*1

|

200*2

|

300*1

|

300*2

|

||||||

|

Use power (KW)

|

|

0.2

|

0.3

|

0.6

|

0.8

|

0.8

|

1.2

|

||||||

|

Equipment dimensions (mm)

|

L

|

1816

|

1816

|

2500

|

2500

|

3255

|

3455

|

||||||

|

|

W

|

756

|

910

|

850

|

935

|

985

|

1295

|

||||||

|

|

H

|

1040

|

1040

|

1270

|

1270

|

1600

|

1600

|

||||||

|

Reference weight (kg)

|

|

190

|

275

|

360

|

470

|

820

|

1350

|

||||||

Product details

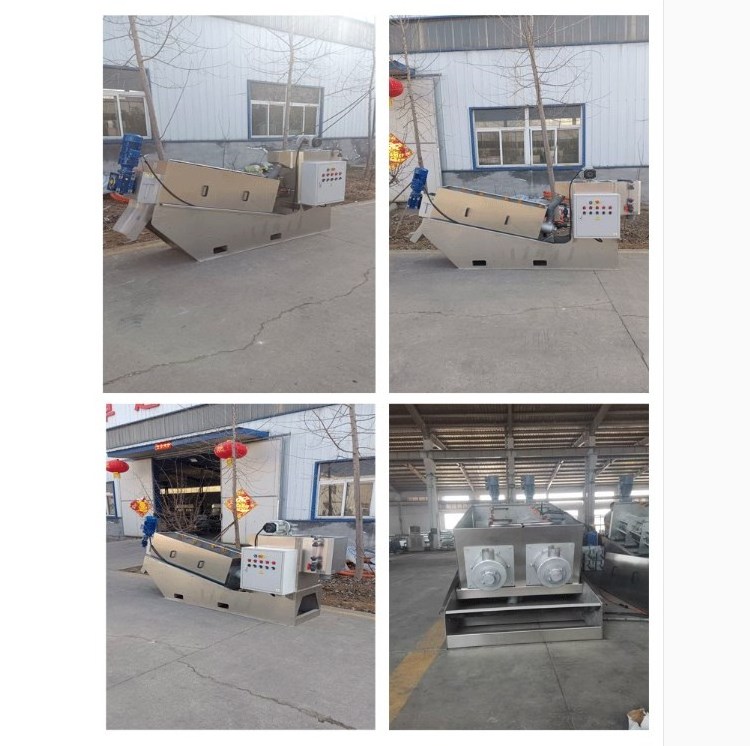

Real picture

Hot Searches