- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2000

-

Machine Type:

-

Coiling Bending Machine

-

Raw Material:

-

Steel Bar

-

Power:

-

CNC

-

Extra Services:

-

Welding / Brazing

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Bending angle:

-

±0-180°

-

Traction steel speed:

-

110m/min(MAX)

-

Single wire Diameters:

-

5-12mm

-

Color:

-

Support Customized

-

Material:

-

Steel Material

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Feihong

-

Year:

-

2024

-

Weight (KG):

-

2000

-

Machine Type:

-

Coiling Bending Machine

-

Raw Material:

-

Steel Bar

-

Power:

-

CNC

-

Extra Services:

-

Welding / Brazing

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Bending angle:

-

±0-180°

-

Traction steel speed:

-

110m/min(MAX)

-

Single wire Diameters:

-

5-12mm

-

Color:

-

Support Customized

-

Material:

-

Steel Material

Description of Product

CNC stirrup bender can automatically complete the straightening, lengthening, bending and cutting of steel wire, so that it can save time, labor and materials. With high processing precision and efficiency, it can realize fully automated, uninterrupted assembly line for steel wire processing. The machine is widely used in railways, highways, bridges, real estate, large-scale wire processing plants and other fields.

|

Model |

FHG-10D |

|

diameter |

5-10mm |

|

Traction motor power |

Synchronous servo moto 5.5KW |

|

Bending motor power |

Synchronous servo moto 3kw |

|

Cutting motor power |

Mechanical cut,3kw brake motor |

|

Rated total power |

16.5kw |

|

Overall dimension |

2500mm*960mm*1800mm |

|

Overall machine weight |

1000kg |

|

Bending angle |

0-135° one-way bending |

|

Length tolerance |

±1mm |

|

Touchable screen |

10 Inch |

|

System |

Feihong6.0CNC System |

|

Traction steel speed |

110m/min(MAX) |

|

Bending speed |

1200°/sec |

|

Rated voltage |

380V/220V/110V/415V440V |

|

Pneumatic system pressure |

≥0.7Mpa |

|

Air compressor power |

4KW |

Please note: we can custom machine according to your detail requirement.

Finished Stirrup Photos

Machine Features

· The stirrup bending machine adopts servo controlling system;

· Automatically accomplish the functions of rebar's feeding, straighten, bending and cutting etc.;

· Max bending diameter of rebar is 14mm;

· Continuously bend various stirrup of plane figure;

· Widely used in construction industry and rebar manufacturing enterprise;

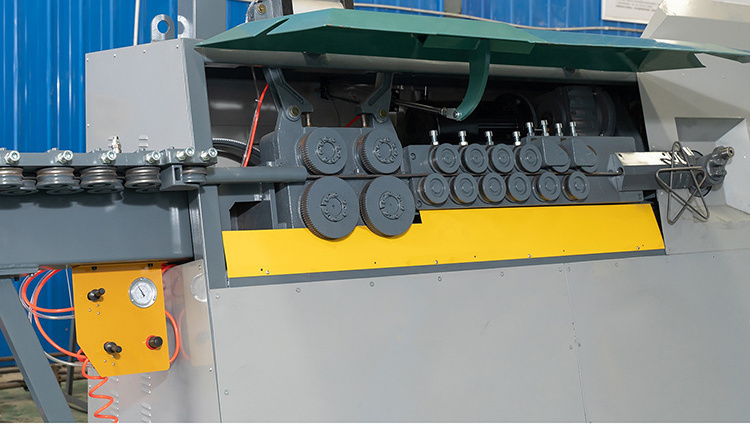

Adjustable Traction and Straightening Wheels

Pre-Straightening Wheels

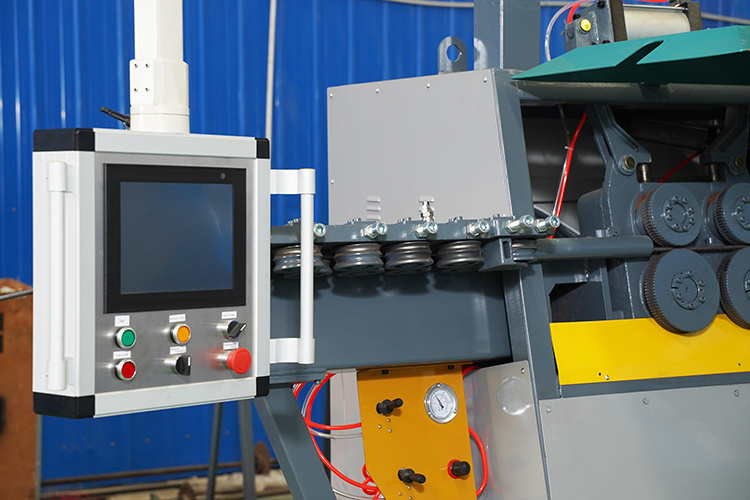

PLC Controll and Touch Screen

Servo Contro System

1.CNC stirrup bender can digitally control the traction and pressing amount according to the steel wire diameter, and the electric control detects the bending motion, makes the operation simple and the work more stable.

2. The bending moulds are made by special technology, has high surface hardness and durability.

3. The split type fixed blade design without the overall replacement, it’s convenient maintenance, reduce cost.

4. The full closed loop control of high precision servo drive makes the length accuracy of the machining reach to ± 1mm, and the angle accuracy reach to ± 1 degrees

5. The electronic control system can store nearly hundreds of commonly used graphics, and can be directly export stored graphics according to the requirements.

6. According to the calculation of 12 hours per day, the output of equipment can reach 15T.

7. The equipment with daily cleaning device, it can easily maintain the equipment and prolong the service life of the equipment

Machine in factory

Packing & Delivery

Stirrup bending machine will be packed wooden case. It is suitable for long distance sea shipment.

Our Factory

Our Service

Pre-sale Service

1. According to your requirements to help you design a reasonable solution, choose a reasonable equipment .

2. In-depth explanation of customer service scheme by design experts.

Sale Service

1. Provide the video to help you to learn about how the device works.

2. Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

FAQ

1. Q: Are you a factory or trading company?

A: We are a professional manufacturer.

2. Q: Can you do OEM?

A: Yes, we can do OEM as client’s requirement.

4. Q: All products have a warranty?

A: YES, Our warranty term is One Year.

5. Q: What about the delivery time?

A: Usually 15-30 days after down payment.

6. Q: What is the biggest advantage of the company?

A: Stable Better Quality and Perfect Service.