Henan Borben Boiler Co., Ltd. has been committed to the manufacturing and research and development of industrial boilers since its establishment. At present, the company has held A class A boiler manufacturing license, American ASME standard "S" (power boiler), "U" (pressure vessel) license seal and other international certifications, is the leader of industrial boiler manufacturers. The high-quality products produced by Bolben boiler sell well at home and abroad, covering all industries such as food, paper, electronics, heating and so on.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5400*2200*2400

-

Weight:

-

18t

-

Design fuel:

-

Biomass Pellet

Quick Details

-

Core Components:

-

Boiler main body

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

borben

-

Dimension(L*W*H):

-

5400*2200*2400

-

Weight:

-

18t

-

Design fuel:

-

Biomass Pellet

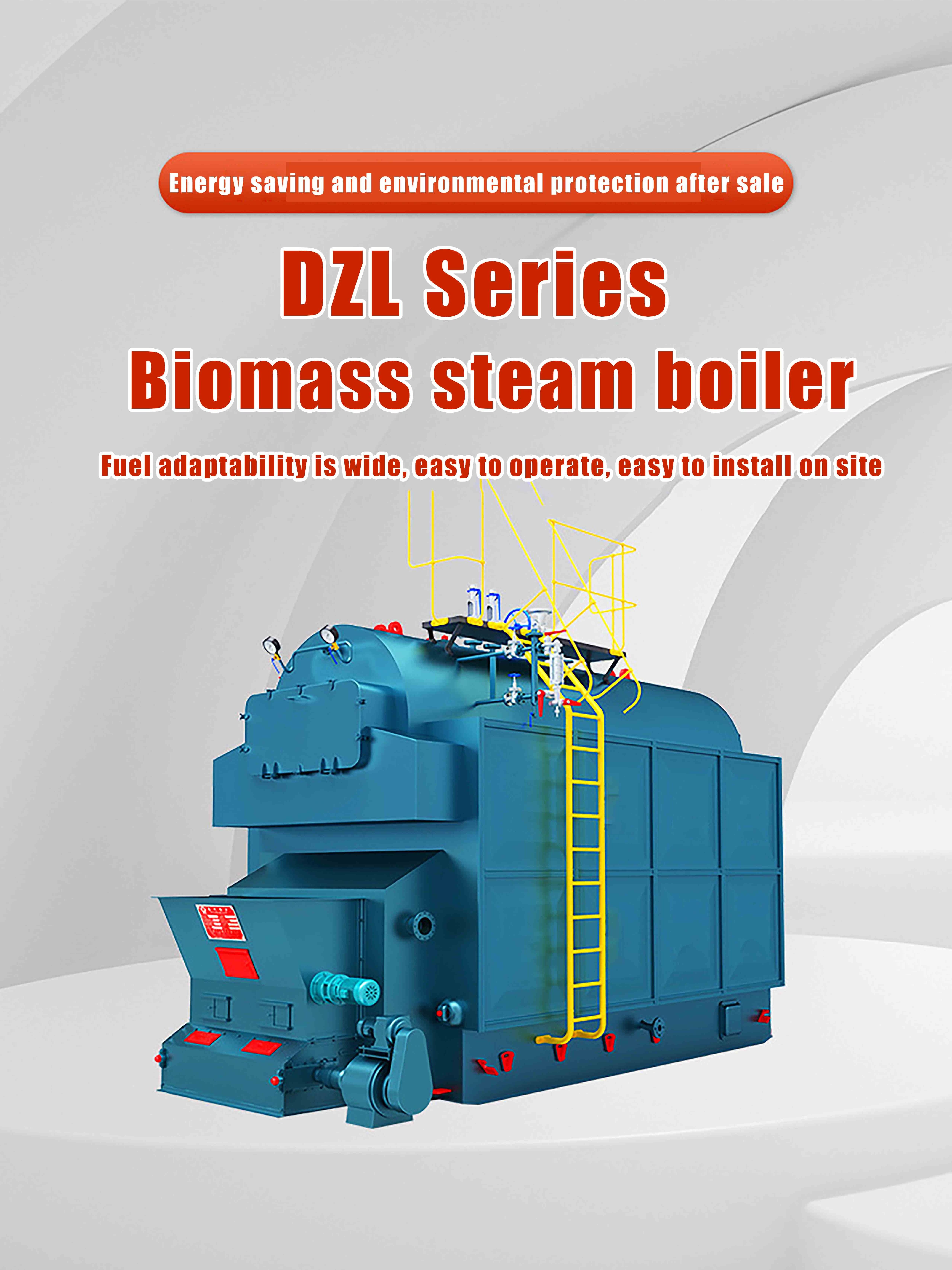

Simple structure

Technical characteristics

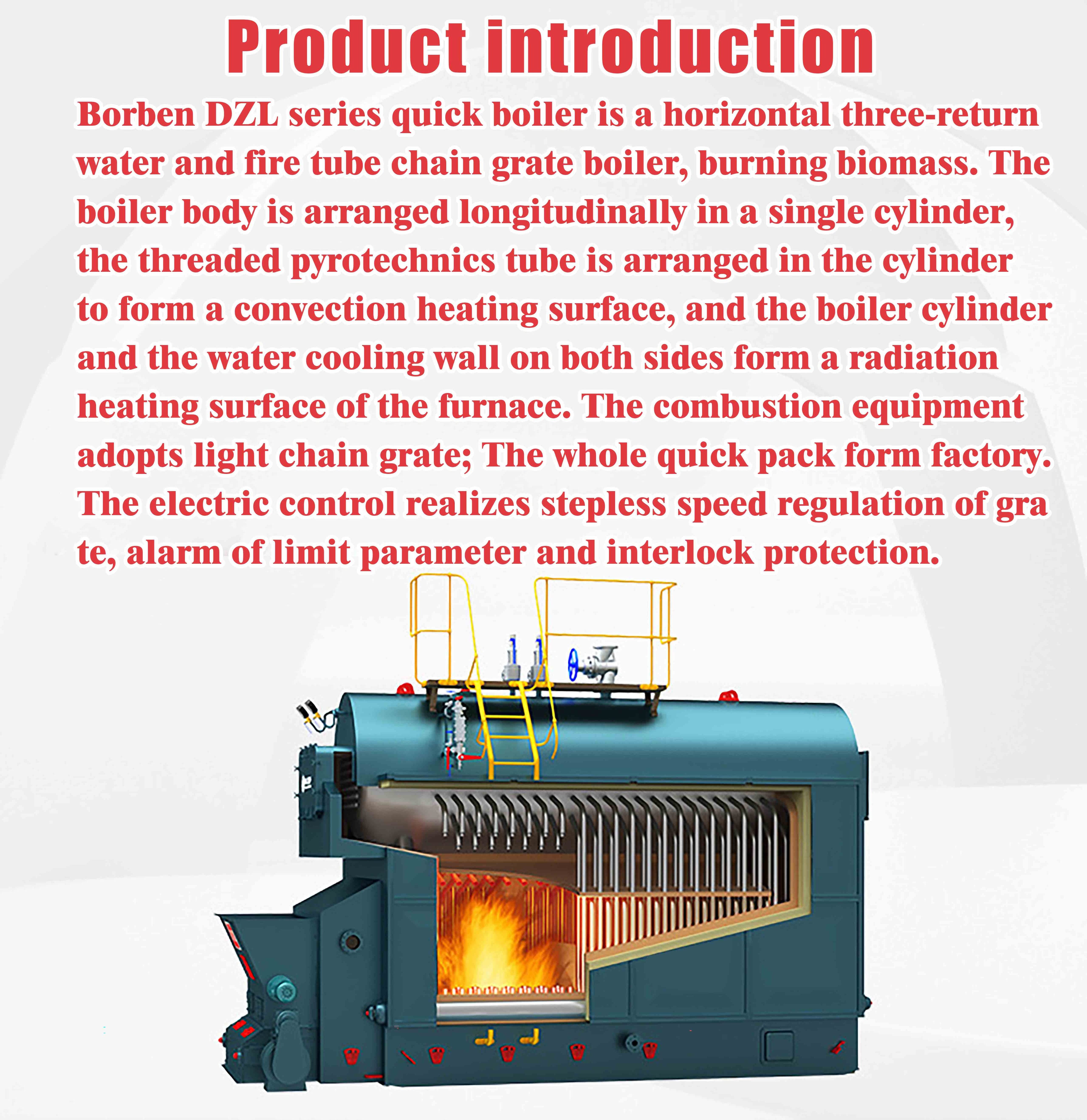

(1) The cylinder is composed of arch tube plate and threaded smoke pipe, so that the cylinder is changed from a quasi-steel body to a quasi-elastic structure, and the pulling member in the tube plate area is cancelled and the stress is reduced. The smoke pipe in the tube plate is changed from two return trips to one return trips, which solves the problem of tube plate cracks.

(2) Due to the arrangement of the riser row in the lower part of the drum, the dead water area at the bottom of the drum is eliminated, so that the mud is not easy to deposit, and the high temperature area of the drum can be cooled well to prevent the bulge in the lower part of the drum.

(3) The use of high efficiency heat transfer threaded smoke pipe, to obtain enhanced heat transfer effect, to achieve the boiler heating, pressure boost characteristics, improve the thermal efficiency of the boiler.

(4) Compact structure, compared with the same type of boiler, small size, saving boiler room infrastructure investment.

(5) Stable operation, convenient adjustment, sufficient output.

(6) The threaded smoke pipe is used to strengthen heat transfer, improve the heat transfer coefficient and thermal efficiency, because the flue gas has a disturbing effect in the pipe. The smoke pipe is not easy to accumulate ash, and plays the role of self-cleaning.

(7) The splayed wall in the furnace and the exit smoke window have a certain dust reduction effect. The original dust concentration of the boiler is controlled below the standard, and the boiler dust emission reaches the national environmental protection regulations.

Type parameter

|

Serial number

|

item

|

unit

|

Technical parameter

|

Technical parameter

|

|

|

|

||||

|

1

|

Model number

|

|

DZH1-0.7-AII

|

DZH1-1.0-AII

|

DZH2-0.7-AII

|

DZH2-1.25-AII

|

DZH4-1.25-AII

|

||||

|

2

|

Overall dimension

|

M

|

3.9×1.85×3.12

|

3.9×1.85×3.12

|

5.2×2.40×3.30

|

5.20×2.40×3.30

|

5.6×2.44×3.4

|

||||

|

3

|

Evaporation capacity

|

t/h

|

1

|

1

|

2

|

2

|

4

|

||||

|

4

|

Working pressure

|

Mpa

|

0.7

|

1

|

0.7

|

1.25

|

1.25

|

||||

|

5

|

Steam temperature

|

℃

|

171

|

184

|

171

|

194

|

194

|

||||

|

6

|

Design thermal efficiency

|

%

|

77

|

77

|

77

|

78

|

78

|

||||

|

7

|

Hourly coal consumption

|

kg/h

|

119

|

119

|

235

|

235

|

410

|

||||

|

8

|

Boiler heating area

|

m2

|

39.4

|

43.93

|

53.6

|

73.6

|

146.3

|

||||

|

9

|

Grate area

|

m2

|

1.9

|

1.9

|

3.74

|

3.74

|

3.93

|

||||

|

10

|

Combustion mode

|

|

Layer firing

|

|

|

|

|

||||

|

11

|

Applicable coal

|

|

Class II bituminous coal

|

|

|

|

|

||||

|

12

|

Boiler weight

|

t

|

9.2

|

10.3

|

12.6

|

13.2

|

17.8

|

||||

Performance advantage:

Hot Searches