- Product Details

- {{item.text}}

Quick Details

-

Length:

-

Customers Requested, 330mm per pce to 450mm per pce or customized

-

Usage:

-

Industry

-

Hardness:

-

T3-T8

-

Al (Min):

-

99.7%

-

Wall Thickness:

-

0.8-8.0mm

-

Model Number:

-

ZJD

-

Brand Name:

-

Zhongjda

-

Aluminum & Alloy:

-

6063-T5 or 7001-T6

-

Color:

-

silver black gold or grey

-

Finish:

-

Anodizing

-

7001 Pole ID:

-

8.5mm,9.5mm 11mm or customized

-

6063 Pole ID:

-

11mm to 28mm or customized

-

Accessories:

-

shockcord and endtip

-

7001 Pole type:

-

pole with an insert

-

6063 Pole type:

-

pole with a neck end

-

Name:

-

7001 aluminum telescopic extension pole with spring button lock

Quick Details

-

Grade:

-

6000 series and 7000 series

-

Tolerance:

-

±5%

-

Place of Origin:

-

Liaoning, China

-

Length:

-

Customers Requested, 330mm per pce to 450mm per pce or customized

-

Usage:

-

Industry

-

Hardness:

-

T3-T8

-

Al (Min):

-

99.7%

-

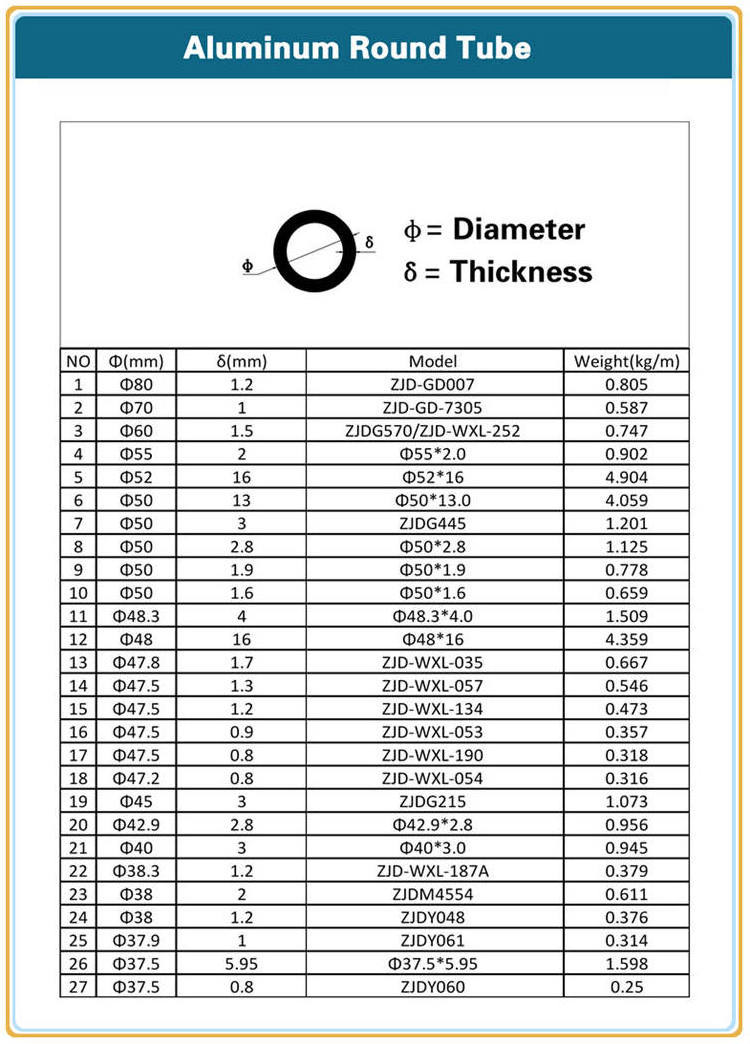

Wall Thickness:

-

0.8-8.0mm

-

Model Number:

-

ZJD

-

Brand Name:

-

Zhongjda

-

Aluminum & Alloy:

-

6063-T5 or 7001-T6

-

Color:

-

silver black gold or grey

-

Finish:

-

Anodizing

-

7001 Pole ID:

-

8.5mm,9.5mm 11mm or customized

-

6063 Pole ID:

-

11mm to 28mm or customized

-

Accessories:

-

shockcord and endtip

-

7001 Pole type:

-

pole with an insert

-

6063 Pole type:

-

pole with a neck end

-

Name:

-

7001 aluminum telescopic extension pole with spring button lock

7001 aluminum telescopic extension pole with spring button lock

| Aluminum Alloy |

6063, 6005, 6005A, 6105, 6101, 6082, 6061 |

| Tempers | T4 , T5 , T6 |

|

Extrusion Capacity

2750 Ton, 10" Press

|

|

|

Surface Treatment

Mill finish , Sand Blasting , Anodizing , Wood grain , Electrophoresis painting , Powder coating * Powder coating thickness: 60-120um * Anodizing thickness: 8-25um |

|

|

|

Fabrication

Cutting Countersinking Punching Notching Bending Deburring Drilling Tapping

Milling

Forming

|

|

Design

*Engineering -CAD Shape Design

|

|

|

Standard Dies Shape |

|

|

Angles

(equal)

,

Angles

(unequal)

,

C shapes

,

Caps

,

Carpet bar

,

Channels

,

Corners

|

|

|

Tolerance |

|

|

According to GB5237.1-2008

or as per agreement

|

|

|

Industry Standards |

|

|

ISO9001: 2008 , ISO14001: 2004 , ISO10012 , AAA grade standardize corporate |

|

| Testing | |

|

Validation

,

Durability

,

Reliability

,

Mechanical

,

Chemical

,

Physical

,

Dimensional

,

|

|

*Spiral Bundle: Extrusions are stacked and tightly wrapped with a stretch film for finish protection.

*Shrink Sleeve: Extrusions are individually covered with a heat shrink film that tightly adheres to the

profile for finish protection.

*Interleave / Kraft: Extrusions are serpentine interleaved with PEP and Kraft for finish protection.

*Paper Layer / Box: Extrusions are layered, separated by paper and boxed for finish protection.

*Box: Extrusions are placed in custom cardboard boxes for finish protection.

*Custom Crate: Extrusions can be placed in a custom wooden shipping crate for further protection.

SUPPLYING YOU WITH SOLUTIONS

Phone support

: speak to a friendly voice you trust to get the job done

Industry leading practises:

take the stress out of material control

On the case:

we make sure every order is chased

In the know:

one step ahead, recording the progress of your order

Comprehensive technology:

we use the latest technology to stay ahead

Mail us any time:

fast and reliable responses to inbound email

| Q1: What are the advantages of using the 6000 series of alloys in aluminum extrusions ? |

|

A: The 6000 series , which incorporates magnesium and silicon, provide good extrudability, strength, corrosion resistance, formability and machinability -- which explains why it’s also ZJD’s alloy of choice for all our aluminum extrusions . |

| Q2: If I wish to send an electronic drawing to you, what types of files can you accept? |

|

A: We accept many file formats such as DXF, DWG and IGES. |

|

Q3: Why do extrusion companies always ask me to sign off on a drawing before they can order tooling if I’ve already provided a drawing? |

|

A: Oftentimes, we find a few key dimensions that are missing from the original drawing that need to be clearly identified. Other times, we have taken exception to a tolerance, dimension, alloy, note, surface condition, etc. It’s just our way of documenting exactly what we have agreed upon. |

| Q4: What is the difference between anodized and mill finished ? |

|

A: Mill is the raw state of aluminum as extruded - no surface treatment. Anodized (also known as Satin Clear or Clear Anodized ) is an electrolytic process. This process increases

corrosion resistance and weather resistance.

|

| Q5: What About Anodizer Rack Marks? |

|

A: Electrical contact must be made to each part to be anodized . The more electrical current required, the greater the electrical contact. The size of the contact therefore

depends on the

anodizing

process and the size of the part being

anodized

.

|

|

Q6: What is your closest sea-port ?

|

|

A: Dalian City SeaPort .

|