A pipe per bending all individually preparing five action sequence and 10 sections of speed, allows the operator to match the use, improve work efficiency, reduce the fitting interference

- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.05

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Power (kW):

-

5.5

-

Weight (KG):

-

2200

-

Type:

-

Tube bender

-

Max bending capacity:

-

38MM

-

Bending thickness:

-

2MM

-

Usage:

-

Pipe and tube bending

-

Application:

-

Pipe processing

-

Voltage:

-

220V/380V/440V

-

Weight:

-

2200kg

-

Demension:

-

4200X950X1200mm

-

Color:

-

Customized

Quick Details

-

Machine Type:

-

DW38CNC-4A-2S-V

-

Bending Radius (mm):

-

10 - 180

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

0.05

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BLMA

-

Power (kW):

-

5.5

-

Weight (KG):

-

2200

-

Type:

-

Tube bender

-

Max bending capacity:

-

38MM

-

Bending thickness:

-

2MM

-

Usage:

-

Pipe and tube bending

-

Application:

-

Pipe processing

-

Voltage:

-

220V/380V/440V

-

Weight:

-

2200kg

-

Demension:

-

4200X950X1200mm

-

Color:

-

Customized

Products Description

Main features

* Fully automatic and CNC pipe bending machine

* Equipped with 2 servo motor programmable axis

* Feeding: servo motor drive; Rotation: servo motor drive

* Bending: hydraulic and encoder control; Servomotor with reducer.

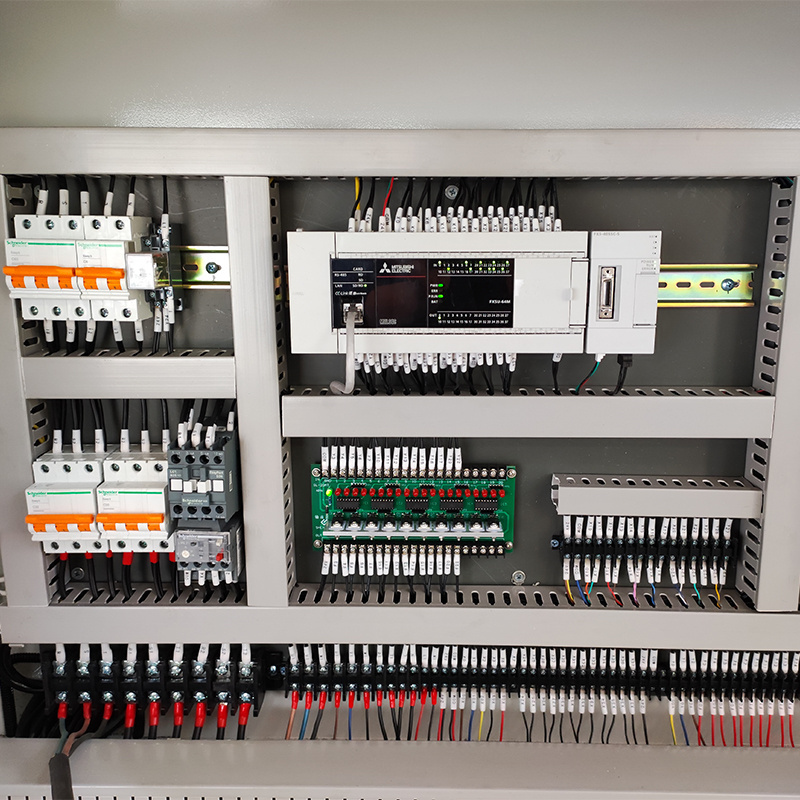

* Imported hydraulic system and PLC(standard) unit or IPC(optional).

* Automatic lubrication system for moving areas.

* Self-diagnostic system, detecting the error immediately.

* Multiple groups pipe-bending information storage.

* Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature.

* Touch screen and human/machine interface control provide user friendly operations.

|

Max bending capacity

|

Ø38mmx2mm

|

|

Max bending radius

|

No limited

|

|

Min bending radius

|

According to pipe diameter

|

|

Max bending degree

|

190°

|

|

Max effective distance of mandrel

|

3000mm

|

|

Feeding method

|

Direct feeding/clamping feeding

|

|

Bending speed

|

Max85°/s

|

|

Rotary speed

|

Max 200°/s

|

|

Feeding speed

|

Max1200mm/s

|

|

Bending accuracy

|

±0.1°

|

|

Rotary accuracy

|

±0.1°

|

|

Feeding accuracy

|

±0.1mm

|

|

Information inputting method

|

Working value (Y, B, C)

|

|

Bending method

|

Servo bending

|

|

Hydrualic motor power

|

5.5kw

|

|

Bending servo motor power

|

3KW

|

|

Rotary servo motor power

|

750W

|

|

Feeding servo motor power

|

2KW

|

|

Head left and right moving servo motor power

|

1KW

|

|

Max storage unit (3)

|

1000 groups

|

|

Max oil pressure

|

14Mpa

|

|

Machine weight

|

2200kg

|

PLC Controller

Recommend Products

Bending sample

Our services

Pre-service

1.We will help you confirm the model of our machine according to your offered pipe information.

2.You are very welcome to see our machine how to work in the factory before you place an order

with us.

with us.

Aftersales-service:

1.

Our machine is easy to use. Operation manual and teaching video will be sent out with machine.

We also offer free training in our factory, the following is our training contents:

Detailed function of our machine, 1 hour;

NC control using, 0.5 hour;

Tooling installation and adjustment, 0.5-1 hours;

Maintenance and repair, 0.5-1 hours;

Real operation according client products, 1-2 hours.

During the training period,we offer free pick-up,hotel and food.

2. We guarantee machine quality for 13 months, during this period, if spare parts of the machine are not man-made damage, we can send the component to the customer by DHL, TNT freely.

3.Our factory provide the service for the customer forever, if the customer need operation help,we

provide 24 hours on-line reply service.

provide 24 hours on-line reply service.

Hot Searches