- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TZ 8104-TZ 8169

-

Protection Level:

-

IP65

-

Operating Temperature:

-

-10-+65

-

Product name:

-

limit switch

-

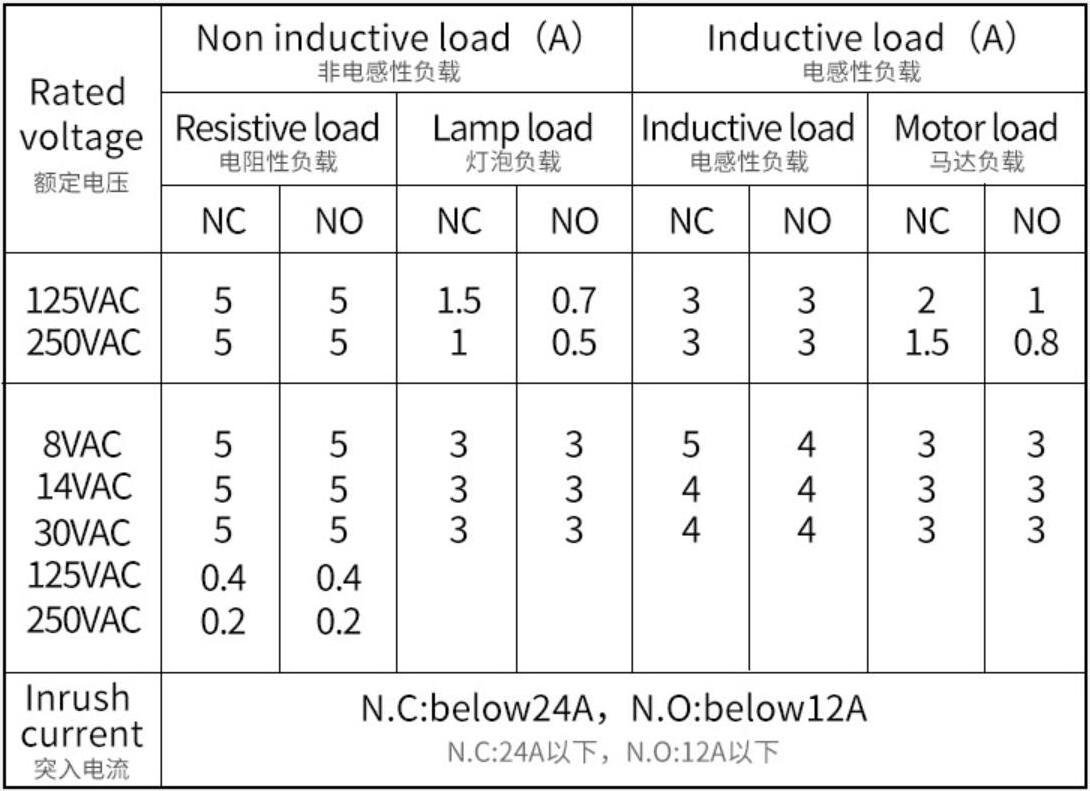

Rated voltage:

-

125/250VAC,8-1250VDC

-

Inrush current:

-

N.C:below 24A, N.O:below 12A

-

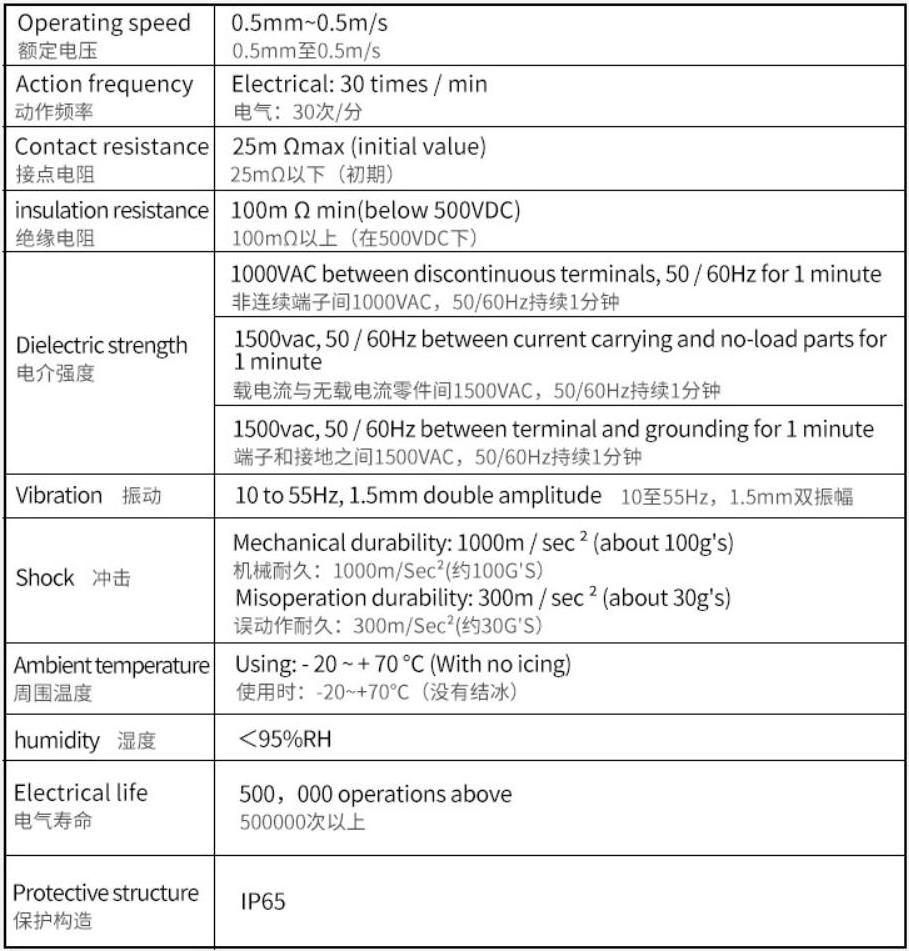

Operating speed:

-

5mm-0.5m/s

-

Operating frequency:

-

Electical: 30 Operations/min

-

CONTACT RESISTANCE:

-

25m Max.(initial Value)

-

INSULATION RESISTANCE:

-

100m Min.(below 500VDC)

-

Vibration:

-

10 ~55Hz Complex Amplitude

-

Shock:

-

Mechanical durable:1000/sec2

-

Weight:

-

About 130 to 190g

Quick Details

-

Max. Voltage:

-

250V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MINYANG

-

Model Number:

-

TZ 8104-TZ 8169

-

Protection Level:

-

IP65

-

Operating Temperature:

-

-10-+65

-

Product name:

-

limit switch

-

Rated voltage:

-

125/250VAC,8-1250VDC

-

Inrush current:

-

N.C:below 24A, N.O:below 12A

-

Operating speed:

-

5mm-0.5m/s

-

Operating frequency:

-

Electical: 30 Operations/min

-

CONTACT RESISTANCE:

-

25m Max.(initial Value)

-

INSULATION RESISTANCE:

-

100m Min.(below 500VDC)

-

Vibration:

-

10 ~55Hz Complex Amplitude

-

Shock:

-

Mechanical durable:1000/sec2

-

Weight:

-

About 130 to 190g

Product description:

A travel switch (also known as a limit switch) is a commonly used small current main control device. By utilizing the collision of moving parts in production machinery to activate their contacts, the control circuit can be connected or disconnected to achieve certain control objectives. Usually, these types of switches are used to limit the position or stroke of mechanical movement, causing the moving machinery to automatically stop, move in reverse, change speed, or move back and forth according to a certain position or stroke.

In electrical control systems, the function of position switches is to achieve sequential control, positioning control, and detection of position status. Used to control the stroke and limit protection of mechanical equipment. Construction: Composed of an operating head, contact system, and housing.

In actual production, the travel switch is installed in a pre arranged position. When the module installed on the moving parts of the production machinery collides with the travel switch, the contact of the travel switch acts to achieve circuit switching. Therefore, a travel switch is an electrical device that switches circuits based on the travel position of moving parts, and its working principle is similar to a button.

Travel switches are widely used in various machine tools and lifting machinery to control their travel and provide terminal limit protection. In the control circuit of the elevator, a travel switch is also used to control the speed of opening and closing the car door, the limit of automatic door opening and closing, and the upper and lower limit protection of the car.

Travel switches can be installed on relatively stationary objects (such as fixed frames, door frames, etc., referred to as stationary objects) or moving objects (such as cranes, doors, etc., referred to as animals). When an animal approaches a stationary object, the connecting rod of the switch drives the contact of the switch to cause the closed contact to open or the open contact to close. Control the operation of circuits and mechanisms by changing the opening and closing status of switch contacts.

Product features:

High reliability: The travel switch can complete the switch action in a short time, ensuring the stability of the circuit and reliable current transmission. In addition, its service life is longer due to its simple structural design and easy maintenance.

Quick response: The travel switch can achieve high-speed switching operation, usually completing switching in milliseconds.

Compact structure: The design of the travel switch allows for compact installation, suitable for smaller spaces.

Cost effectiveness: Due to the basic materials and manufacturing technology used in the production process, the cost of travel switches is relatively low, which makes them widely applicable to various mechanical equipment in different industries.

Wide application range: Travel switches are not only used in machine tools and lifting machinery, but also in elevator control systems to control the speed of door opening and closing, automatic door closing limit, and upper and lower limit protection of the elevator car.

Safety: The travel switch has overload protection and short circuit protection functions, which can monitor abnormal current and voltage situations, and automatically cut off the power supply when a fault is detected, ensuring equipment and personal safety.

Automation control: Travel switches can be integrated with other automation system components (such as timers and sensors) to achieve automation control and further optimize production processes.

Adjustable and diversified: The travel switch can adjust the switch quantity and control mode according to different needs, and there are multiple types to choose from, including high-temperature resistant, waterproof, fireproof, and explosion-proof, suitable for different environmental applications.

Easy to operate: The travel switch is easy to operate and maintain, and some models also have a self diagnostic function for easy troubleshooting.

Product parameters:

Product details:

Workshop:

Certificate:

Product application cases:

Transportation and packaging:

FAQ:

Unable to trigger: This may be due to a wiring problem or damaged components. You can check whether the wiring is correct, or replace the limit switch with a new one to troubleshoot.

False operation or false alarm: This may be caused by contaminated or damaged sensor elements. You can clean the sensor element or replace damaged parts.

Electrical problems: Such as disconnected cables or damaged circuits can cause the limit switch to fail. Checking the cable connections and checking that the circuit is working properly is key to solving the problem.

Mechanical Damage: Limit switches can fail due to damaged mechanical parts or inaccurate accuracy. In this case, the limit switch may need to be replaced or repaired.