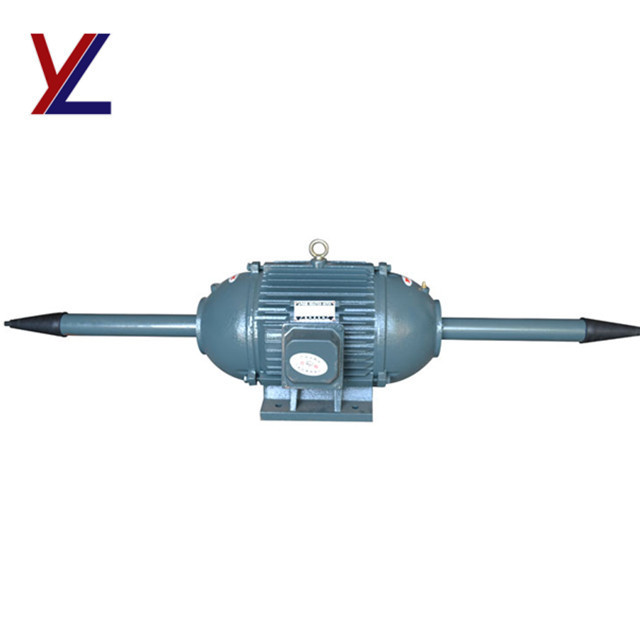

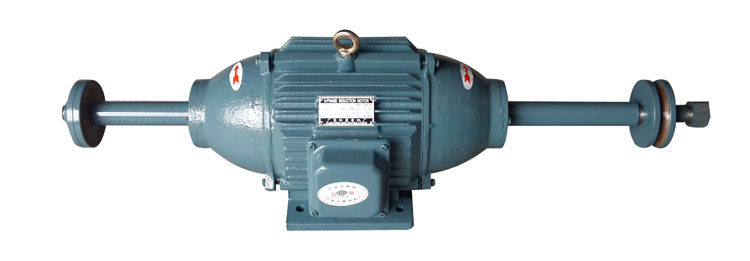

This machine is designed as a tapered thread shaft with self-locking function. It can also be modified into a splint shaft according to the demand, which is convenient and flexible. It is the preferred polishing machine for small cost polishing.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YL

-

Model Number:

-

YL-PM 17

-

Dimensions:

-

1200mm*300mm*300mm

-

Wheel Diameter:

-

300mm

-

Frequency:

-

2 HP

-

Weight:

-

75KG

-

KEY:

-

bench buffer

-

Keyword:

-

bench buffer

-

Name:

-

Double head bench polishing and buffing machine for watch case

-

Type:

-

eyeglasses buffing machine

-

Power:

-

380v/50HZ/ 3 Phase

-

Usage:

-

polishing and buffing machine

Quick Details

-

Voltage:

-

120V, 220V/50HZ, 120V/60HZ, 16A, 110V/60Hz, 230-240/50Hz

-

Rated Voltage:

-

380V

-

Rated Input Power:

-

3KW,4KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YL

-

Model Number:

-

YL-PM 17

-

Dimensions:

-

1200mm*300mm*300mm

-

Wheel Diameter:

-

300mm

-

Frequency:

-

2 HP

-

Weight:

-

75KG

-

KEY:

-

bench buffer

-

Keyword:

-

bench buffer

-

Name:

-

Double head bench polishing and buffing machine for watch case

-

Type:

-

eyeglasses buffing machine

-

Power:

-

380v/50HZ/ 3 Phase

-

Usage:

-

polishing and buffing machine

Products Description

Double-head grinding machine for stainless steel surface polishing to clear and mirror finish

1.The double-head grinding machine with tapered thread shaft

Suitable for polishing cloth wheel/polishing hemp wheel/nylon wheel, the middle hole is :12MM

2. The double-head grinding machine with splint shaft

Suitable for 25 hole polishing wheels, the widest wheel is 100MM

3. The double speed grinding machine with splint shaft

Suitable for 25 hole polishing wheel, width can exceed 100MM,

The two-speed polishing machine has two powers :2.2KW&3KW,3KW&4KW, and 4KW & 5.5KW

4. The double speed grinding machine with tapered thread shaft

The two-speed polishing machine has two powers :2.2KW&3KW,3KW&4KW, and 4KW & 5.5KW

Technical parameters

Two end tip polishing machine for (single speed) traditional polishing machine, economical, simple operation, with two stations for two people at the same time polishing; The coil in the motor is made of copper wire to increase the life of the motor; Ex-factory design for the tapered thread shaft, with self-locking function, can also be modified into a splint shaft according to demand, convenient and flexible, is the first choice of small cost polishing machine.

|

Item

|

Nominal power

|

Rotate speed(r/min)

|

Voltage

|

Size(L*W*H, mm)

|

W/unit

|

3-phase Asynchronous Polishing Electromotor

|

|

AUTO-PM017-1

|

1.5KW

|

|

380V

|

1100*400*390

|

30KW

|

Operation mode: S6=60% Class of Insulation of Stator Winding: B Taper of Shaft stretch taper thread of side: 16 degree

|

|

AUTO-PM017-2

|

2.2kw

|

2860r/min

|

380V

|

1100*400*390

|

32KW

|

|

|

AUTO-PM017-3

|

3KW

|

2900r/min

|

380V

|

1100*400*390

|

48KG

|

Operation mode: S6=60%

Class of Insulation of Stator Winding: B Taper of Shaft stretch taper thread of side: 16 degree

|

|

AUTO-PM017-4

|

4KW

|

2900r/min

|

380V

|

1100*400*390

|

52KG

|

4KW, RPM2900,

Voltage :380V

|

|

AUTO-PM017-5

|

5.5KW

|

2900r/min

|

380V

|

1100*400*390

|

80KW

|

|

|

AUTO-PM017-6

|

7.5KW

|

2900r/min

|

380V

|

1100*400*390

|

84KW

|

|

|

PM017-D1

|

2.2/3KW

|

1420-2900 r/min

|

380V

|

1100*400*390

|

75KG

|

Double speed polishing machine, you can adjust the speed to 1420 or 2900 as your needs.Suitable for polishing biger metal parts.

|

|

PM017-D2

|

4/5.5KW

|

1440-2900 r/min

|

380V

|

1200*340*340

|

80kg

|

Double speed polishing machine, you can adjust the speed to 1440 or 2900 as your needs.Suitable for polishing smaller metal parts.

|

Excellent with hand control, Fine polishing for metal parts surface as jewelry, rings, watch case, nacklace, buckle, tableware, arc knife, metal edge, aluminum polishing process .

The double-head polishing machine is (single speed) traditional polishing machine, economical and economical, easy to operate, with two stations for both of them to be polished simultaneously.

Matching cloth wheel or wind wheel, and polishing wax can make the product achieve the desired polishing effect.

Double speed and point polisher is based on the single speed machine combine two speed coil in a motor casing, the effect of the implementation used a double speed, by the speed of the rotary switch to choose the suitable for polishing, make the machine more flexible.

You can adjust the spee

|

3-phase induction Motor

|

|

|

|

Operation mode

|

S6=60%

|

|

|

Rated Voltage

|

220V

|

|

|

3KW and Below

|

Connection Y

|

|

|

4KW and Above

|

Triangle Connection

|

|

|

Nominal Power

|

50HZ

|

|

|

Working temperature

|

below 104 degree

|

|

|

Height above sea level

|

below 1000M

|

|

|

Nominal Power

|

1.5,2.2,3,4,5.5,7.5KW (2,3,4,5.5,7.5,10HP)

|

|

|

Others Nominal Voltage

|

220/380V,346V,420V or 60 HZ rate

|

|

|

Characteristic

|

Small volume, light, attractive appearance, firm structure, reliable performance

|

|

Application

1. For polishing and grinding from different angle on different work pieces.

2. Two work stations allow two workers polishing or two polishing processes by one worker at a time.

3. All casting parts ensure durable use.

4. Widespread use in process of polishing in different industries.

5. Using rough and soft Soft muslin buff allows polishing on different position and from different angel.

6. Double speed motor allows exchange between 2 different power and rotate speed.

7. For grinding and polishing of flat and camber surface of plate materials and nails.

8.Working platform can be set up to 90 degree, allow 2 workers polishing on both sides.

Hot Searches