- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PEEK 5600G

-

Specification:

-

Customized

-

Length:

-

1M;2M;3M or Customized

-

Thickness:

-

Customized

-

Standard:

-

ISO9001

-

Color:

-

Natural

-

Product name:

-

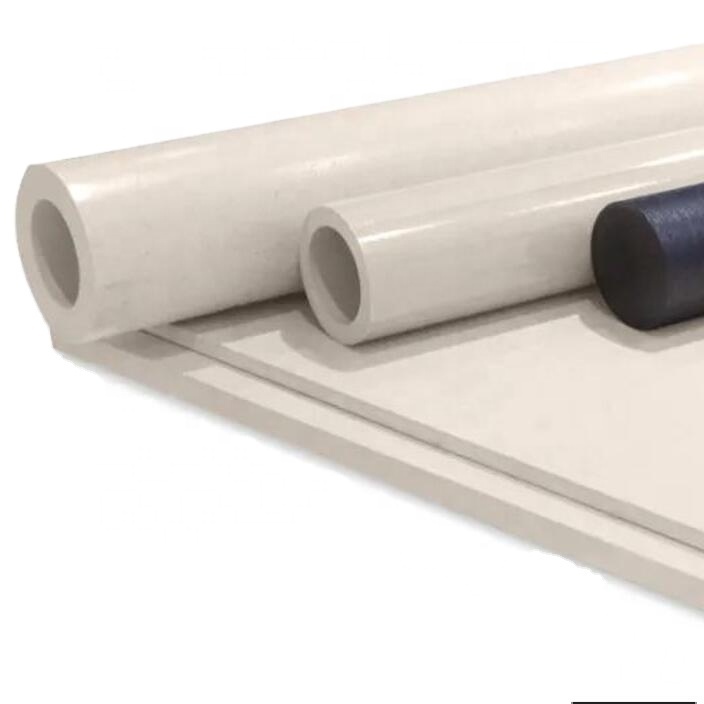

PEEK Tube

-

Density:

-

1.31 g/cm

-

Melting point:

-

343℃

-

Distortion Temperature:

-

163 ℃

-

Continuous service Temperature:

-

260 ℃

-

Tensile Strength (23℃):

-

100 MPa

-

Bending Strength (23℃):

-

163 MPa

-

Flammability:

-

V-0

Quick Details

-

Processing Service:

-

Cutting, Grinding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Junhua PEEK

-

Model Number:

-

PEEK 5600G

-

Specification:

-

Customized

-

Length:

-

1M;2M;3M or Customized

-

Thickness:

-

Customized

-

Standard:

-

ISO9001

-

Color:

-

Natural

-

Product name:

-

PEEK Tube

-

Density:

-

1.31 g/cm

-

Melting point:

-

343℃

-

Distortion Temperature:

-

163 ℃

-

Continuous service Temperature:

-

260 ℃

-

Tensile Strength (23℃):

-

100 MPa

-

Bending Strength (23℃):

-

163 MPa

-

Flammability:

-

V-0

Products Description

▲ >130 PEEK tube specifications for your option.More size option.▲ > 20 tons of PEEK products we have in stock around the year. Fast delivery time.

▲ Any size of PEEK tube is cutted as your material requirement. Free cutting service.

▲ 580mm Ultra big PEEK tube.Bigger diameter tube.

▲ Irregular PEEK tubes are developed as the buyer`s project requirement.Innovation in technology.

▲ Any size of PEEK tube is cutted as your material requirement. Free cutting service.

▲ 580mm Ultra big PEEK tube.Bigger diameter tube.

▲ Irregular PEEK tubes are developed as the buyer`s project requirement.Innovation in technology.

PEEK seals

Peek seals are used in areas that require the control of things for example like liquids and natural gasses to prevent

leakage.There are several different applications and areas that PEEK seals can be found in such as valves, compressors, packers and blow out preventers. The high-performance thermoplastic polymer PEEK is perfectly suited for this sealing applications due to its excellent properties such as high temperature tolerance, good mechanical and chemical resistance and its hardness and

rigidity.

Peek seals are used in areas that require the control of things for example like liquids and natural gasses to prevent

leakage.There are several different applications and areas that PEEK seals can be found in such as valves, compressors, packers and blow out preventers. The high-performance thermoplastic polymer PEEK is perfectly suited for this sealing applications due to its excellent properties such as high temperature tolerance, good mechanical and chemical resistance and its hardness and

rigidity.

PEEK back-up rings

Back up rings are normally used in high pressure environments in combination with an O-ring or seal. ChinaPEEK back up rings have a high compressive strength and thermal stability. In conjunction with temperature,chemical and fatigue resistance, the back up

ring material functions as an added insurance when spikes in pressure can cause the O-ring to fail and the stronger, tougher, back up ring is used to help prevent failure.

ring material functions as an added insurance when spikes in pressure can cause the O-ring to fail and the stronger, tougher, back up ring is used to help prevent failure.

PEEK valve seats

Valve seats are used in environments to control the flow of fluids, allowing them to flow freely and also have the ability to lose to prevent the flow. ChinaPEEK is a commonly used material and considered premium in valve seats applications due to its excellent chemical and thermal properties. The high temp polymer remains resistant despite the continuous exposure of hot water and steam and increases the torque requirement of the valve due to

its rigidity.

|

NO.

|

Patent Name

|

Patent Number

|

Apply Date

|

Issue Date

|

|

1

|

PEEK capillary tubes continuous extrusion process and technology

|

ZL201310425335.3

|

2013.09

|

2017.03

|

|

2

|

PEEK rotor production technology

|

ZL201310423283.6

|

2013.09

|

2017.05

|

|

3

|

PEEK wearing bush for the weaving machine

|

ZL201310423033.2

|

2013.09

|

2017.01

|

|

4

|

PEEK slim sheet continous extrusion process and technology

|

ZL201402447189.4

|

2014.08

|

2014.12

|

|

5

|

PEEK needle bar frame for medical

|

ZL201721255079.8

|

2017.09

|

2018.04

|

|

6

|

PEEK Cassette for liquid-crystal display (LCD)

|

ZL201721254977.1

|

2017.09

|

2018.05

|

|

7

|

PEEK cable extrusion technology with electromagnetic preheat function

|

ZL201721255076.4

|

2017.09

|

2018.04

|

|

8

|

PEEK injected and metal imbedded star wheel

|

ZL201721254833.6

|

2017.09

|

2019.03

|

|

9

|

PEEK glass frame

|

ZL201721839957.0

|

2017.12

|

2018.08

|

|

10

|

PEEK bottle clamp for food processing and filling machine

|

ZL201721839847.4

|

2017.12

|

2018.09

|

Hot Searches