- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.37*1.8*0.95m

-

Weight:

-

350 kg

-

Marketing Type:

-

Hot Product

-

Core Components:

-

spares

-

Material:

-

Carbon Steel

Quick Details

-

Max. Capacity:

-

100-150KG/H

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HUIJU

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1.37*1.8*0.95m

-

Weight:

-

350 kg

-

Marketing Type:

-

Hot Product

-

Core Components:

-

spares

-

Material:

-

Carbon Steel

Product Description

|

Model No

|

HJ-FFP100

|

|

Power

|

15kw/380v

|

|

Feeding Power

|

0.4kw

|

|

Cutting Power

|

0.4kw

|

|

Capacity

|

100-150kg/hour

|

|

Size

|

1.37*1.8*0.95m

|

|

Weight

|

350KG

|

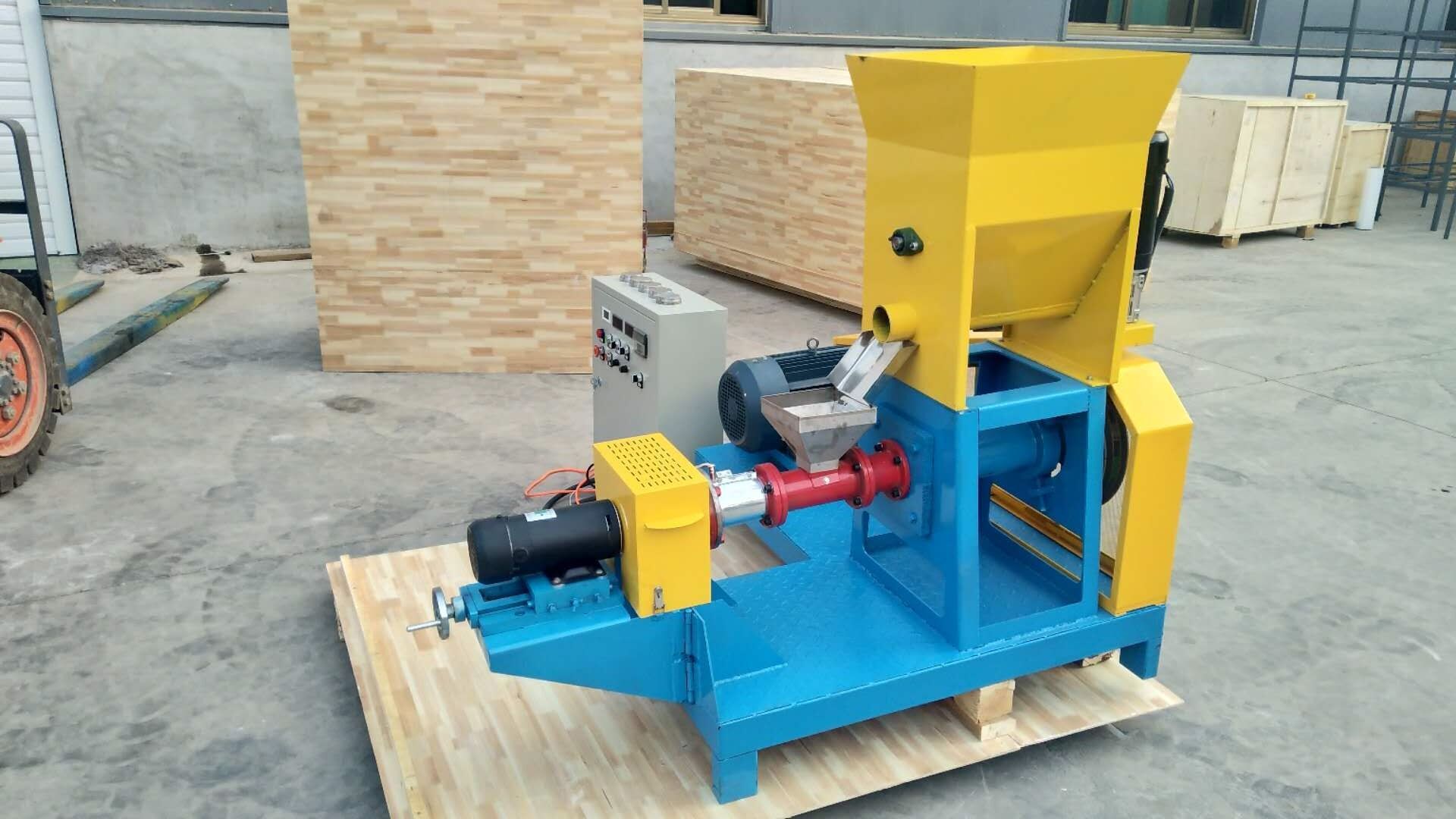

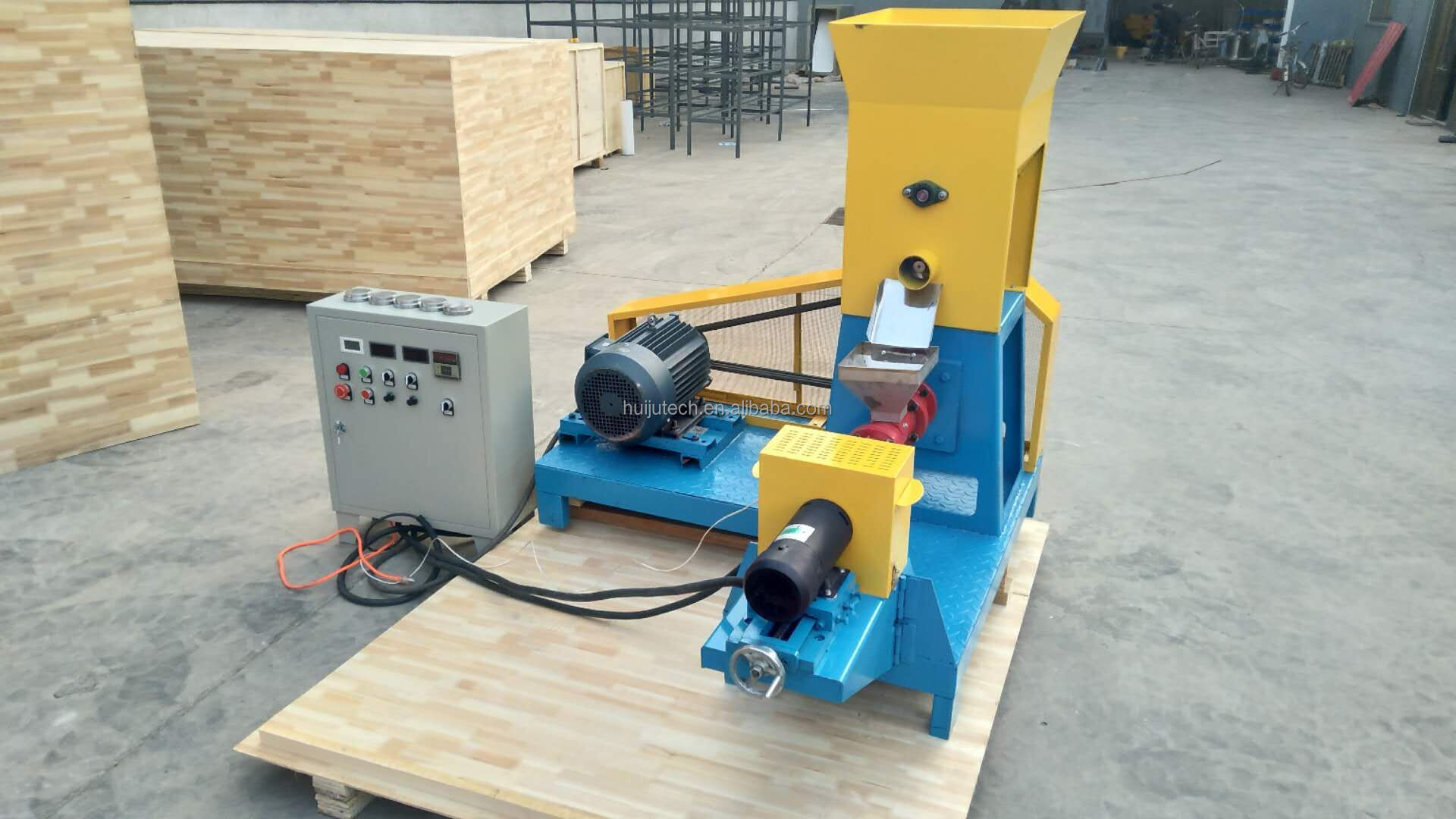

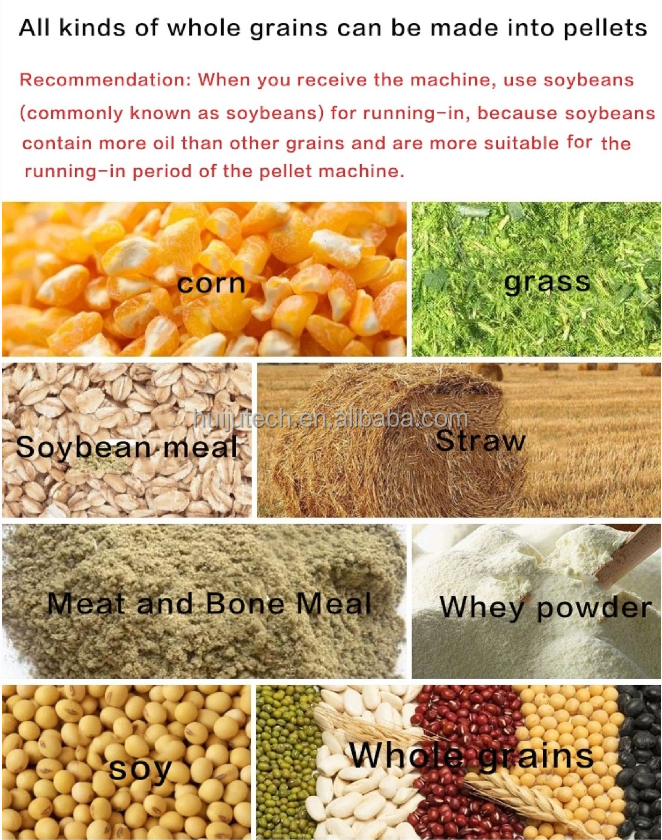

Specification

The dry puffing machine is mainly composed of a feeder (bucket), an extrusion puffing device, a power and transmission system, a frame, an electric control system, and the like.

1, Feeder (bucket)

The feeder (bucket) is an automatic speed regulation type, which is composed of a hopper, a pusher spiral, a discharge pipe, a casing and the like.

2. Extruding device

The extrusion puffing device is the core part of the puffing machine, and the corresponding combination is selected according to different uses, that is, puffing different materials and different discharging modes. The extrusion and expansion device can be divided into two parts, the cavity combination and the driving component combination. The cavity combination is generally composed of the feeding box, the compression chamber, the discharging box (the ring gap discharge does not have this piece), and the adjusting screw plug (expansion full) Composition of fat soybean or other single raw materials: The driving component combination is mainly composed of a bearing housing assembly, a main shaft extrusion spiral (group), a bullet head and the like.

The material is pushed from the feed box from the extrusion spiral (set) to the compression chamber to obtain a preliminary extrusion, heating, and then continuously subjected to different degrees of extrusion and heating until discharge. When puffed whole fat soybean powder or other single raw materials (single hole discharge), the undischarge effect is not obtained, the gap between the screw plug and the bullet can be adjusted, and the template of different discharge apertures is not replaced, and the material is discharged. The hole diameter series is 1mm1.5mm in 2mmp3mn and 3.5mmp4mmp5mp6.8m. Users can choose from them. The bearing housing assembly mainly refers to the bearing housing, the left and right end covers, the fuel filler, the oil mark, the bearing, the oil seal and the like. The function of the installation is to support the main shaft, install the bearing accessories, and lubricate the cooling bearings.

3, electronic control system

The electrical control system, according to the host power size and feeding form, the configuration is also different, the machine independent control box, fixed on the rack.The motors of this system can start and stop independently. In the use, the starting sequence is as follows: main motor, one cutting motor, one feeding motor

1, Feeder (bucket)

The feeder (bucket) is an automatic speed regulation type, which is composed of a hopper, a pusher spiral, a discharge pipe, a casing and the like.

2. Extruding device

The extrusion puffing device is the core part of the puffing machine, and the corresponding combination is selected according to different uses, that is, puffing different materials and different discharging modes. The extrusion and expansion device can be divided into two parts, the cavity combination and the driving component combination. The cavity combination is generally composed of the feeding box, the compression chamber, the discharging box (the ring gap discharge does not have this piece), and the adjusting screw plug (expansion full) Composition of fat soybean or other single raw materials: The driving component combination is mainly composed of a bearing housing assembly, a main shaft extrusion spiral (group), a bullet head and the like.

The material is pushed from the feed box from the extrusion spiral (set) to the compression chamber to obtain a preliminary extrusion, heating, and then continuously subjected to different degrees of extrusion and heating until discharge. When puffed whole fat soybean powder or other single raw materials (single hole discharge), the undischarge effect is not obtained, the gap between the screw plug and the bullet can be adjusted, and the template of different discharge apertures is not replaced, and the material is discharged. The hole diameter series is 1mm1.5mm in 2mmp3mn and 3.5mmp4mmp5mp6.8m. Users can choose from them. The bearing housing assembly mainly refers to the bearing housing, the left and right end covers, the fuel filler, the oil mark, the bearing, the oil seal and the like. The function of the installation is to support the main shaft, install the bearing accessories, and lubricate the cooling bearings.

3, electronic control system

The electrical control system, according to the host power size and feeding form, the configuration is also different, the machine independent control box, fixed on the rack.The motors of this system can start and stop independently. In the use, the starting sequence is as follows: main motor, one cutting motor, one feeding motor

Packing & Delivery

plywood box for export

Related Product

Hot Searches