Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Qingdao City,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(Customized)

-

Dimension(L*W*H):

-

20*3.5*4 meters

-

Power (kW):

-

90

-

Weight:

-

20000 KG

-

Name:

-

WPC Wood Plastic Profile Production Line

-

Processing Type:

-

Profile Extrusion

-

Keywords:

-

WPC Wood Profile Extrusion Machine

-

Product name:

-

Profile Making Machine

-

Final product:

-

WPC profile,WPC decking,WPC floor,WPC wall cladding

-

Motor:

-

SIEMENS Brand

-

Productiong size:

-

150-400mm width

-

Raw material:

-

PP PE WPC

-

Machine type:

-

WPC Profile Extrusion Machine

-

Usage:

-

WPC Decking Flooring Panel Machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Qingdao City,China

-

Brand Name:

-

YIERTAI

-

Voltage:

-

380V/3P/50HZ(Customized)

-

Dimension(L*W*H):

-

20*3.5*4 meters

-

Power (kW):

-

90

-

Weight:

-

20000 KG

-

Name:

-

WPC Wood Plastic Profile Production Line

-

Processing Type:

-

Profile Extrusion

-

Keywords:

-

WPC Wood Profile Extrusion Machine

-

Product name:

-

Profile Making Machine

-

Final product:

-

WPC profile,WPC decking,WPC floor,WPC wall cladding

-

Motor:

-

SIEMENS Brand

-

Productiong size:

-

150-400mm width

-

Raw material:

-

PP PE WPC

-

Machine type:

-

WPC Profile Extrusion Machine

-

Usage:

-

WPC Decking Flooring Panel Machine

Product Description

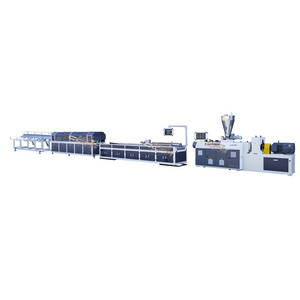

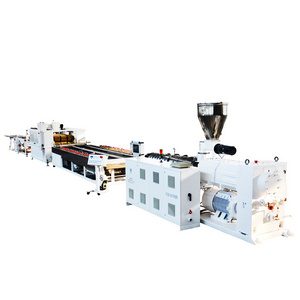

Wood plastic board extrusion machine line

PVC/UPVC WPC wood plastic composite WPC profile extrusion line

for making window and door frames, photo frames, indoor wall panel and ceiling panel etc. The extrusion line includes conical twin screw extruder, calibration platform, tractor and cutter with dust suction device, product stacker.

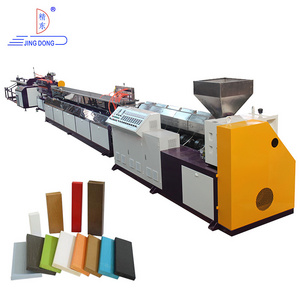

PP PE WPC wood plastic composite WPC profile extrusion line

for making outdoor WPC decking,fence, post, pallet, flooring, chair, wall panel etc.The extrusion line includes conical twin screw extruder, calibration platform, cutting machine with dust suction device, product stacker. Through mixing, granulating, extruding, embossing, sanding,brushing etc processing, the PE WPC profile can be similar with natural wood in appearance and feel.

Application

Wood Plastic Composite products extrusion line Main products:

(1)PP/PE WPC wood plastic composite WPC profile extrusion line for making outdoor WPC decking,fence, post, pallet, flooring, chair, wall panel and ceiling panel etc.

(2)PVC/UPVC WPC wood plastic composite WPC profile extrusion line for making window and door frames, indoor wall panel and ceiling panel etc.

(1)PP/PE WPC wood plastic composite WPC profile extrusion line for making outdoor WPC decking,fence, post, pallet, flooring, chair, wall panel and ceiling panel etc.

(2)PVC/UPVC WPC wood plastic composite WPC profile extrusion line for making window and door frames, indoor wall panel and ceiling panel etc.

(3)PVC/UPVC WPC wood plastic composite WPC door panel extrusion line for making door panel.

(4)PVC/UPVC WPC wood plastic composite WPC foam board extrusion line for making foam board. The foam board can be used for making furniture,partition,poster board,etc.

Specification

|

Model

|

Motor power(kw)

|

Screw Diameter (mm)

|

L/D ratio

|

RPM

|

Capacity(kg/h)

|

|

MSSJ-30

|

2.2

|

30

|

25

|

0-50

|

8~12

|

|

NSSJ-45

|

7.5~15

|

45

|

25~30

|

0-73

|

15~30

|

|

MSSJ-65

|

15~45

|

65

|

25~33

|

0-90

|

45~150

|

|

MSSJ-75

|

22~90

|

75

|

25~33

|

0-120

|

80~350

|

|

MSSJ-90

|

30~160

|

90

|

25~34

|

0-120

|

80~600

|

|

MSSJ-120

|

90~250

|

120

|

25~34

|

0-120

|

250~800

|

|

MSSJ-150

|

110~355

|

150

|

25~36

|

0-120

|

350~1100

|

Detailed images

Products process:

1)PP/PE+WOOD EXTRUSION LINE CRAFT:

wood milling(wood powder,rice husk)---mixer(plastic+wood)---granulator---wpc extrusion line-embossing/sandering/brush napping

2) PVC+WOOD EXTRUSION LINE CRAFT:

wood milling(wood powder,rice husk)---mixer(plastic+wood)---wpc extrusion line ---embossing/sandering/brush napping

conical double screw extruder

We will supply customer with the according extruder, to achieve the optimal plasticizing state. The electrical system has mainly equipped with imported electric parts. temperature control system precision up to ±1℃.

vacuum setting table and cooling system

Hall-off machine

Automatic pipe cutting machine

Hot Searches