1.What is your MOQ?

Our MOQ is usually only 1 PCS.

2.What is your delievery time?

The time of delievery is around 10-45days.

3.What is the shipping port?

We ship the goods via Xiamen or Shanghai port.

4.What is your payment terms?

We accept 30% T/T in advance,70% in the period of shipment or 100% L/C.

5.How should I contact you?

You can contact us with Trade Manager or send us an email by click Contact Supplier bottom.

6.What is the location of your company?

Our company is located in the Xiamen Fujian Province,China.

If you would like to have a visit, you are much welcome.

7.How about the samples?

We could send you the samples ,most samples are free to send to most places in China.If sent to other countries,transport fee

shoule be paid by you.

8.Why choose us?

1 Genuine produces with excellent quality and competitive price.

2 Cooperating with the customers all over the world and knowing the markets very well.

3 Strongtech is a listed company. Everything can be rest assured working with us.

4 After- Services will be highly-satisfied. Any problems and feedbacks will be answered in a short of time.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LIVTER

-

Model Number:

-

Z0123

-

Ball diameter (mm):

-

5

-

chamfer angle:

-

10

-

Contour radius (mm):

-

7

-

Cutting diameter (mm):

-

20

-

maximum depth of cut:

-

50

-

Functional length (mm):

-

10

-

Helix angle:

-

30

-

Shank diameter (mm):

-

10

Quick Details

-

Material:

-

Diamond

-

Coating:

-

No,

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIVTER

-

Model Number:

-

Z0123

-

Ball diameter (mm):

-

5

-

chamfer angle:

-

10

-

Contour radius (mm):

-

7

-

Cutting diameter (mm):

-

20

-

maximum depth of cut:

-

50

-

Functional length (mm):

-

10

-

Helix angle:

-

30

-

Shank diameter (mm):

-

10

Recommend Products

Products Description

|

Ball diameter (mm)

|

5

|

Useful length (mm)

|

20-50

|

|

chamfer angle

|

10

|

Cutting edge form

|

helical

|

|

Minimum cutting diameter at the center (mm)

|

5

|

Material

|

diamond

|

|

Contour radius (mm)

|

7

|

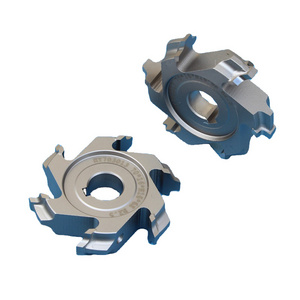

Class

|

Side Mills

|

|

Cutting diameter (mm)

|

20

|

Number of slots

|

5

|

|

maximum depth of cut

|

50

|

blade length

|

20-50(mm)

|

|

Number of effective cutting edges around

|

5

|

Blade diameter

|

30(mm)

|

|

Functional length (mm)

|

10

|

Shank diameter

|

10(mm)

|

|

Helix angle

|

30

|

full length

|

20-50(mm)

|

|

Shank diameter (mm)

|

10

|

Specifications (diameter*full length)

|

10-70(mm)

|

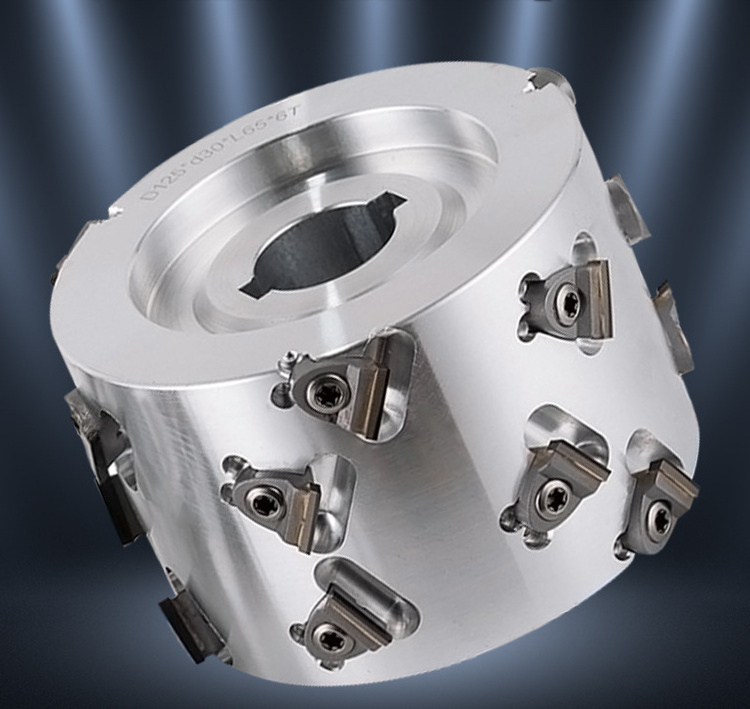

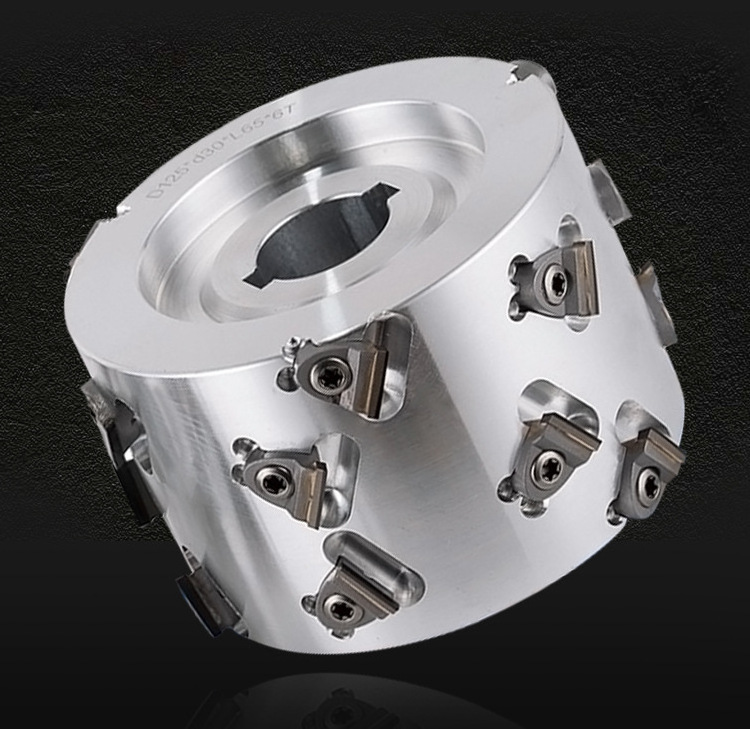

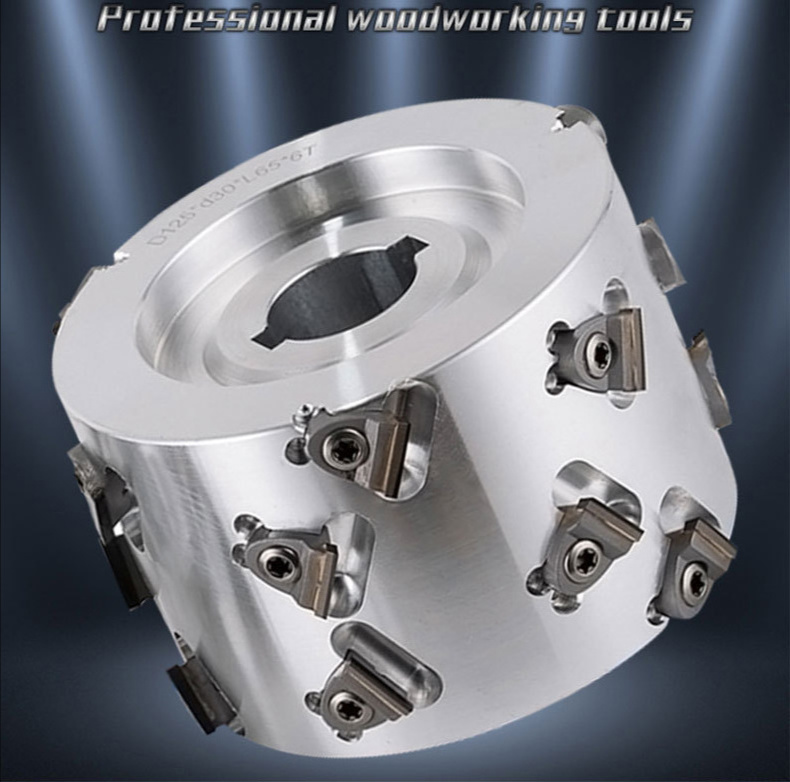

Woodworking PCD pre-milling cutter is a tool commonly used in the wood processing industry. It has the characteristics of high hardness, high wear resistance and high cutting speed, which can greatly improve the efficiency and quality of wood processing. It will be introduced in detail below.

1. Characteristics of woodworking PCD pre-milling cutters

1. High hardness: The cutting part of the woodworking PCD pre-milling cutter is made of polycrystalline diamond (PCD). Its hardness is as high as 8000-10000HV, which is 3-5 times higher than the hardness of carbide cutting tools. Therefore, woodworking PCD pre-milling cutters can easily cut high-hardness materials such as wood, effectively avoiding tool wear and damage.

2. High wear resistance: Since the cutting part of the woodworking PCD pre-milling cutter is made of polycrystalline diamond, its wear resistance is very good, 3-5 times higher than that of carbide tools. In the case of high-speed cutting, the cutting edge of the woodworking PCD pre-milling cutter is very stable and will not wear or deform.

3. High cutting speed: The cutting speed of woodworking PCD pre-milling cutters is very fast, more than 3 times higher than the cutting speed of traditional wood processing tools. This is because the cutting part of the woodworking PCD pre-milling cutter is made of polycrystalline diamond, which has a very low friction coefficient and generates less heat during the cutting process, so the cutting speed can be greatly increased.

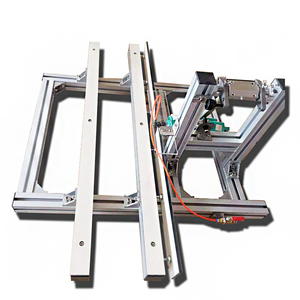

2. Application of woodworking PCD pre-milling cutter

Woodworking PCD pre-milling cutters are widely used in wood processing industries, such as furniture manufacturing, floor manufacturing, wooden door manufacturing, etc. The following are some specific applications of woodworking PCD pre-milling cutters in wood processing.

1. Wood cutting: During the wood cutting process, the woodworking PCD pre-milling cutter can cut wood quickly and accurately, greatly improving the efficiency and quality of wood cutting.

2. Wood milling: In the wood milling process, the woodworking PCD pre-milling cutter can cut wood at high speed and easily complete milling of various complex shapes, such as tenons, slots, engravings, etc.

3. Wood sanding: During the wood sanding process, the woodworking PCD pre-milling cutter can cut wood at high speed, making the wood surface smooth and flat, and improving the processing quality of the wood.

3. Selection of woodworking PCD pre-milling cutters

Choosing a suitable woodworking PCD pre-milling cutter is very important to improve wood processing efficiency and ensure processing quality. Here are some factors to consider when choosing a PCD pre-mill for woodworking.

1. Processing materials: Different wood materials have different hardness and texture, and a suitable woodworking PCD pre-milling cutter needs to be selected for processing. For example, hard wood needs to choose a woodworking PCD pre-milling cutter with high hardness and high wear resistance, while soft wood can choose a relatively soft woodworking PCD pre-milling cutter.

2. Processing size: Choose a suitable woodworking PCD pre-milling cutter according to the size of the wood processing. Larger size woodworking PCD pre-milling cutters can greatly improve processing efficiency, while smaller size woodworking PCD pre-milling cutters are suitable for operations such as fine machining and engraving.

3. Processing accuracy: According to the accuracy requirements of wood processing, select a suitable woodworking PCD pre-milling cutter. High-precision woodworking PCD pre-milling cutters can ensure the accuracy and surface quality of wood processing.

4. Tool brand: Choosing a well-known brand of woodworking PCD pre-milling cutter can ensure the quality of the cutter and after-sales service.

In short, the woodworking PCD pre-milling cutter is a woodworking processing tool with high hardness, high wear resistance and high cutting speed, which can greatly improve the efficiency and quality of wood processing. When choosing a woodworking PCD pre-milling cutter, you need to make a selection based on factors such as processing materials, processing dimensions, and processing accuracy to ensure the best processing effect.

Customer consultation

Our company

FAQ

FAQ

Hot Searches