- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

1000 KG

-

Product name:

-

Log Washer

-

Usage:

-

Mining Washing

-

Color:

-

Customized Color

-

Tank slope:

-

≤12°

-

Size:

-

Customized Size

-

Quality:

-

100% Tested

-

Price:

-

Competetive (Can Negotiate)

-

MOQ:

-

1 Set

-

Installation:

-

Technical Guidance

-

Certification:

-

ISO9001

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Changyi

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

1000 KG

-

Product name:

-

Log Washer

-

Usage:

-

Mining Washing

-

Color:

-

Customized Color

-

Tank slope:

-

≤12°

-

Size:

-

Customized Size

-

Quality:

-

100% Tested

-

Price:

-

Competetive (Can Negotiate)

-

MOQ:

-

1 Set

-

Installation:

-

Technical Guidance

-

Certification:

-

ISO9001

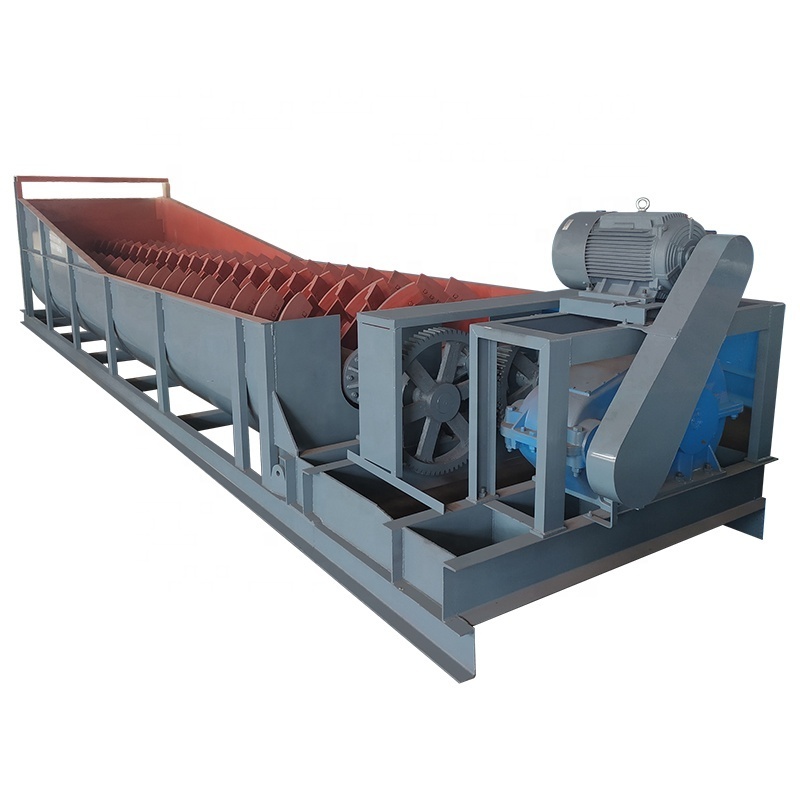

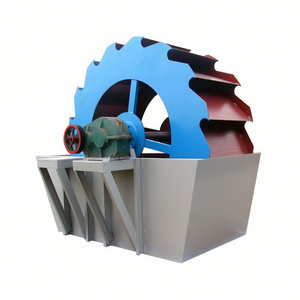

Product Description

Widely used in all kinds of easy to wash and difficult to wash ore washing. The mud content in the ore is more than 20% will block the crusher and chute, and the trough washing machine can make the ore containing mud in more than 20% of the ore in the washing machine spiral stirring, scrubbing to achieve the purpose of separating the ore and mud, the ore after washing is discharged from the discharge port, and the mud water is discharged from the tailings.

Features of Log Washer

1. Large capacity, convenient installation, simple operation, low cost, high efficiency.

2. Log Washers ideal for scrubbing difficult materials such as tough insoluble clays, conglomerates, soft stone and cemented aggregate.

3. High capacity.

4. Replaceable heavy duty conveying paddles.

5. Fabricated with heavy duty shafts.

6. Oversize bearings and gears.

7. Thick-walled shafts.

8. Lower end bolted to fully machined stub shaft. Upper end mounted through flexible coupling to output shaft of gearbox.

9. The compound drive divides the operating load over an optimal combination of oversized helical and spur gears.

10.Continuous grinding and abrading log washer paddles.

11. Adjustable water discharge gates on both sides of lower end of the tub.

Application Areas

Log washer is mainly used to wash the manganese ore, iron ore, phosphate and other minerals.

It is usually used to clean and separate the silt and stains from manganese ore, iron ore and other low-grade mineral.

Working Principle

The left and right spiral shaft completes the scrubbing and lifting of ore, the spiral blade adopts a new design, and the lower end of the spiral shaft adopts advanced polymer wear-resistant materials and sealing technology. Inclined installation, minerals and water from the inlet into the tank body, through the spiral shaft impeller agitation, to achieve the cleaning effect of the ore. After cleaning, the mud and debris flow out through the overflow trough, and the ore sinks into the bottom of the trough and is discharged from the discharge port.

Operational approach:

1. Before operation must be checked according to the check content before starting.

2. After hearing the start signal, be ready to start.

3. Close the switch and start the operation button.

4. The ore of the warehouse must be finished before it can be stopped.

5. Press the miner operation stop button.

6. Turn off the power switch.

7. No notice of power failure and emergency shutdown must immediately pull off the switch.

Technical Parameters

|

Model

|

Rotary speed

(r/min)

|

Capacity

(t/h)

|

Power

(kw)

|

|

2RXL320

|

28

|

10

|

4

|

|

2RXL540

|

23

|

20-40

|

11

|

|

2RXL1200

|

19

|

50-100

|

45

|

Note: Data only for reference, according to customer requirements for design and production.

Details Images

Packaging&Shipping

Hot Searches