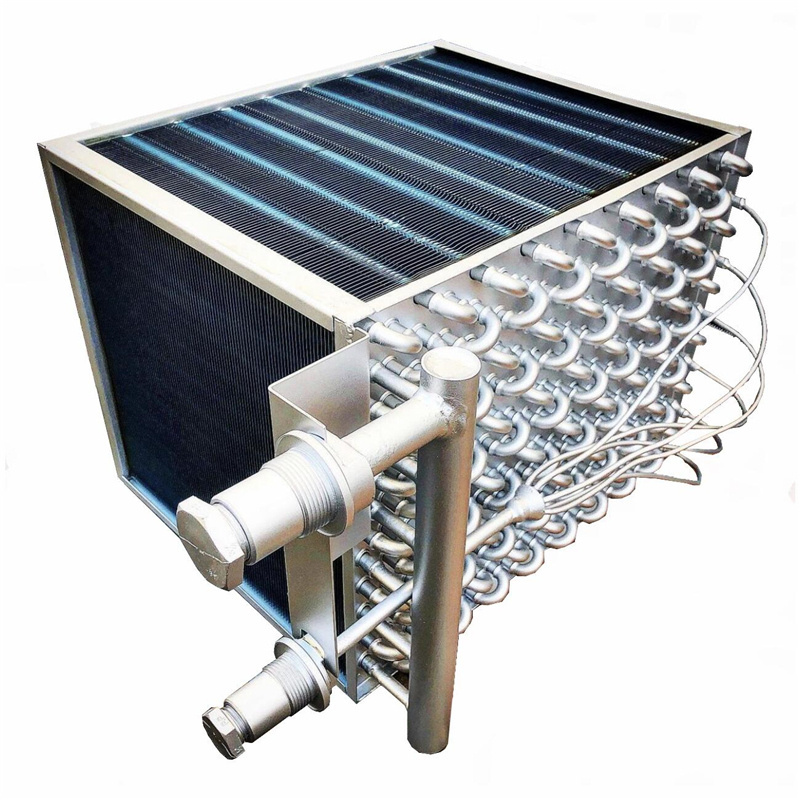

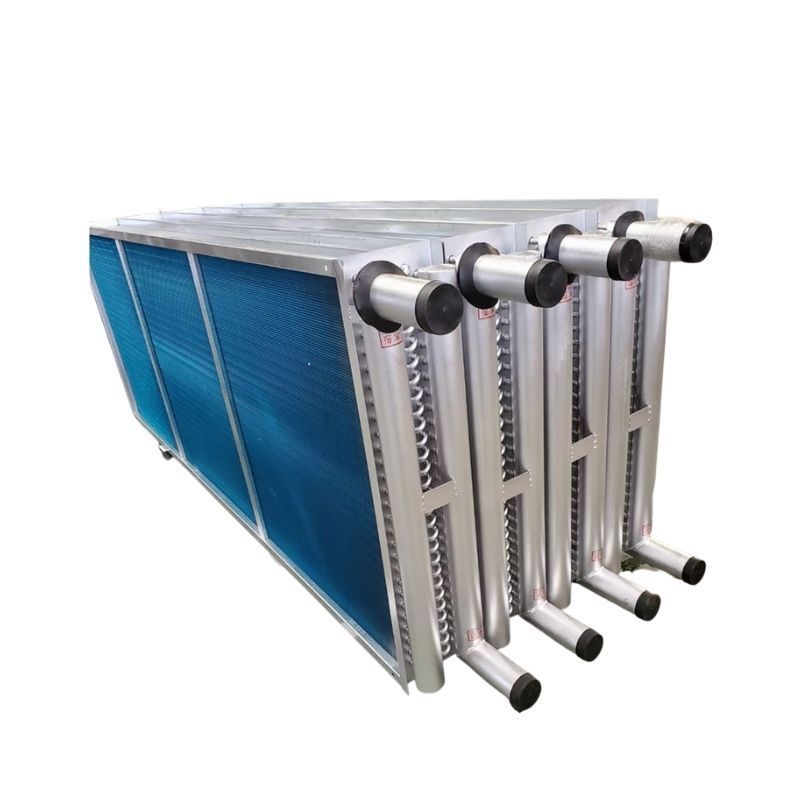

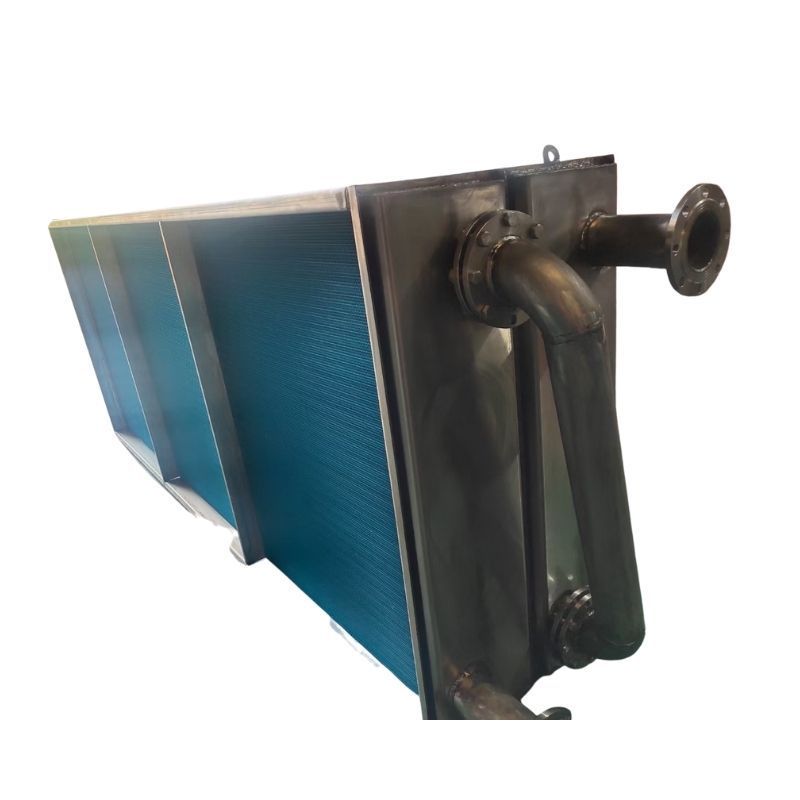

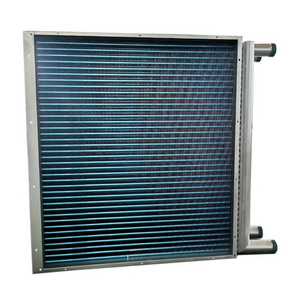

fin heat exchanger has better heat dissipation than the traditional straight tube heat exchanger and is able to transfer heat more quickly.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

CST

-

Liquid Flow Rate:

-

3.5m/s

-

Maximum Working Pressure:

-

20 Mpa

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1030*280*610mm

-

Working Temperature Range:

-

-10-25℃

-

Material:

-

CU, AL,SS304/316,CuNi,Brass,Titanium

-

FIn type:

-

Wave fin

-

Frame:

-

Galvanized steel/SS304,316

-

Tube diameter:

-

9.52/12.7/15.88/20/25mm

-

Application:

-

heat exchanger, evaporator,condenser,radiator

-

Coating:

-

E-coating>Al epoxy>hydrophilic> aluminum

-

Tube type:

-

bare/thread

-

FIn thickness:

-

0.12 mm/Custom made

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Voltage:

-

220V

-

Core Components:

-

stainless steel tube aluminum fin

-

Place of Origin:

-

China

-

Brand Name:

-

CST

-

Liquid Flow Rate:

-

3.5m/s

-

Maximum Working Pressure:

-

20 Mpa

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1030*280*610mm

-

Working Temperature Range:

-

-10-25℃

-

Material:

-

CU, AL,SS304/316,CuNi,Brass,Titanium

-

FIn type:

-

Wave fin

-

Frame:

-

Galvanized steel/SS304,316

-

Tube diameter:

-

9.52/12.7/15.88/20/25mm

-

Application:

-

heat exchanger, evaporator,condenser,radiator

-

Coating:

-

E-coating>Al epoxy>hydrophilic> aluminum

-

Tube type:

-

bare/thread

-

FIn thickness:

-

0.12 mm/Custom made

-

Marketing Type:

-

Hot Product 2019

fin heat exchanger has better heat dissipation than the traditional straight tube heat exchanger and is able to transfer heat more quickly.

Name: Tube

• Material: stainless steel, copper, aluminum, Cu-Ni, brass, titanium • Diameter: 5mm, 7 mm, 7.94mm, 9.52mm, 11.5mm, 12mm, 12.7mm, 15mm, 15.8mm 20mm, 25mm • Smooth, Smooth thick-walled, Grooved, Super grooved (deeper grooves) • Connection to several circuits available

Name: Fin

• Material: Aluminum, Copper Stainless steel, Titanium Hot deep carbon steel, golded

•Coating:

E-coating> Al epoxy>hydrophilic

• Thickness: 0.1-2mm

• Type: wave fin, flat fin , window fin

Name: Frame and casing

• Material: Galvanized steel, Aluminum, Stainless steel Copper, Brass

• Thickness: 1-5 mm

• End plates with or without collets

• Various design of side plates

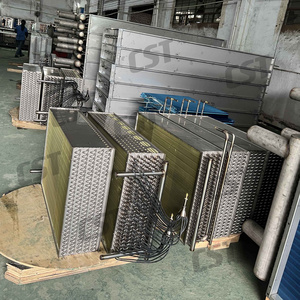

* Sample testing support.

* View our Factory.

* Free parts

* Oneline shill support

VRCOOLERTECH CST Company

Charge air cooler

CST Heat Exchanger Co.,Ltd

Address: Xinsheng Road 56, Luoyang, Changzhou, China. (Near Shanghai)

E-mail: totoro@cstheatexchanger.com