- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

25

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

35 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

50 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DONGXING

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L9m*W2.6m*H2.8m

-

Weight (T):

-

10 T

-

Power(KW):

-

80kw

-

Application:

-

Plastic Products

-

Product name:

-

Muti Step High-speed Thermoforming Machine

-

Keyword:

-

PLA Tableware Making Machine

-

Suitable material:

-

PP,PS,PET,PVC,OPS,PLA

-

Function:

-

Forming - Punching - Cutting - Stacking

-

Max forming area:

-

w720*L600mm

-

Min.Forming Area:

-

420*300mm

-

Travel depth:

-

150mm

-

Sheet width:

-

450-760mm

-

Controller:

-

touch screen

Quick Details

-

Max.Forming Height(mm):

-

150 mm

-

Forming Width (mm):

-

780 mm

-

Forming Length (mm):

-

600 mm

-

Production Speed(Cycles/min):

-

25

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 2 mm

-

Heating Power (kW):

-

35 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

50 L/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DONGXING

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L9m*W2.6m*H2.8m

-

Weight (T):

-

10 T

-

Power(KW):

-

80kw

-

Application:

-

Plastic Products

-

Product name:

-

Muti Step High-speed Thermoforming Machine

-

Keyword:

-

PLA Tableware Making Machine

-

Suitable material:

-

PP,PS,PET,PVC,OPS,PLA

-

Function:

-

Forming - Punching - Cutting - Stacking

-

Max forming area:

-

w720*L600mm

-

Min.Forming Area:

-

420*300mm

-

Travel depth:

-

150mm

-

Sheet width:

-

450-760mm

-

Controller:

-

touch screen

Products Description

|

Technical Parameters

|

|

|

|

|

|

|

|||||

|

Station

|

Four Station

|

Three station

|

Four stations

|

Three station

|

Three station

|

Three station

|

|||||

|

Model

|

DM-060

|

|

Dm-80

|

|

DX-7260

|

DX-FY7190

|

|||||

|

Forming Area

|

W780*L600mm

|

|

W720*L800mm

|

|

W720*L600mm

|

W710*L900mm

|

|||||

|

Forming Depth (Max.)

|

150mm

|

|

150mm

|

|

150mm

|

150mm

|

|||||

|

Sheet thickness

|

0.15-0.2mm

|

|

|

|

0.15-0.2mm

|

0.15-2.0mm

|

|||||

|

cycle period

|

40/min

|

|

|

|

30/min

|

30/min

|

|||||

|

Air pressure

|

7Bar

|

|

|

|

7Bar

|

7Bar

|

|||||

|

Min.Forming Area

|

420*300mm

|

|

420*300mm

|

|

420*300mm

|

|

|||||

|

Sheet width

|

450-810mm

|

|

450-780mm

|

|

450-810mm

|

450-760mm

|

|||||

|

Suitable Sheet

|

PP,PS,PET,CPET,PVC,OPS,PLA,etc.

|

|

|

|

|

|

|||||

|

Power supply

|

AC 380V, 50Hz, Three-phase, Four-wire

|

|

|

|

|

|

|||||

|

Rated power

|

|

100kw

|

|

120kw

|

100kw

|

80kw

|

|||||

|

Heating power

|

20-55kw

|

|

20-55kw

|

|

20-55kw

|

20-55kw

|

|||||

|

Procedure

|

Forming-punching-cutting-stacking

|

Forming-cutting-stacking

|

Forming-punching-cutting-stacking

|

Forming-cutting-stacking

|

Forming-cutting-stacking

|

Forming-cutting-stacking

|

|||||

|

Dimension

|

L11m*W2.8m*H3m

|

L13m*W2.8m*H3m

|

L12m*W2.8m*H3m

|

L14m*W2.8m*H3m

|

L11m*W2.8m*H3m

|

L8m*W2.

6m*H2.8m

|

|||||

|

Weight

|

16T

|

14T

|

18T

|

16T

|

13T

|

10T

|

|||||

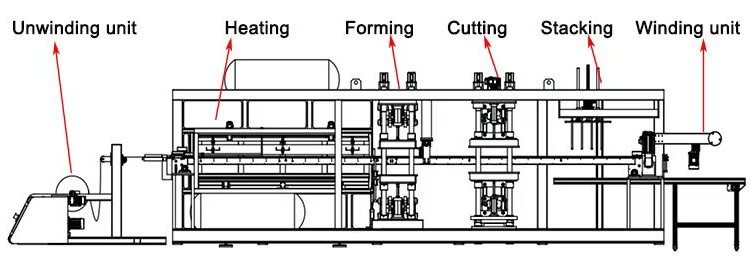

Feeding Part

1.Double material rod automatic mechanical loading roll device, roll diameter 1100mm, can bear 500kg.

Conveying part

1.The chain guide is made of aviation aluminum alloy with surface hard oxygen treatment.

2.The guide rail of Aluminum is full of cooled water can cool the heated sheet efficiently leads to stable conveying.

2.

The guide rail is electrically adjustable and can be adjusted in one direction.

3.

Driven by servo motor, accurate and efficient.

Heating Part

1.Hot oven length is 3 times the forming length,upper oven and lower oven heating ,lower oven with protective steel mesh,high temperature resistant wire,with current overload protection.

2.Far infrared

ceramic heating bricks

Machine Description

Plastic Cup Thermoforming Making Machine

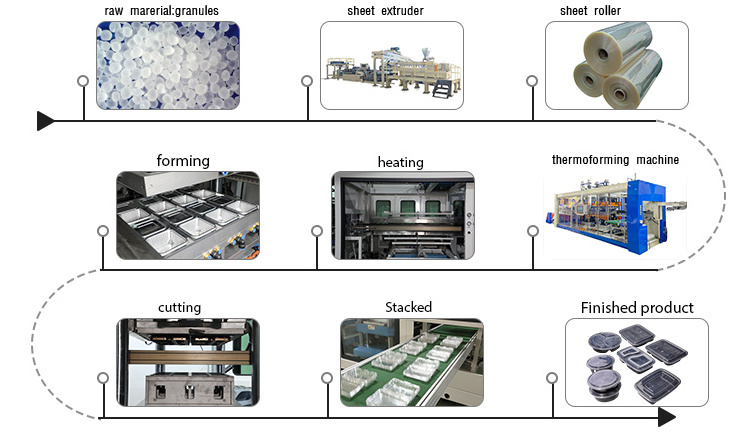

It's full-automatic air pressure thermoforming machine.

Outstanding Features:

1.Machine operation is controlled by PLC and Touch Screen.

2.Adopt four-pillars to fix mold,ensure whole machine precision.

3.

Temperature control module for precise control of individual temperature zones.

4.Easy to operate,outstanding performance,low noise and high quality.

5.The machine adopts

servo stretching

,energy saving 5%-10% than pneumatic stretching,stable speed,precise positioning,noise,and safer operation control.

Heating System Forming System

|

Partial configuration

|

|

|

|

Relay

|

Omron

|

|

|

scram button

|

Schneider

|

|

|

Contactor

|

Schneider

|

|

|

Proximity Switch

|

Omron

|

|

|

Stretching 、Feeding servo motor

|

Delta/Inovance

|

|

|

PLC

|

Omron

|

|

|

Touch screen

|

Taiwan Weintek

|

|

Products Description

3 stations Full Automatic Thermoforming Machine

All uses the servo control system,combined with the advanced automation system.

suitable material:PP,PET,PS,PVC,PE,OPS,biodegradable materials.

Working Station

1. Adopt the structure of four-pillars(40Cr steel) for supporting, which make our forming station more stronger and stable, shock absorption and wear resisting.

2. The parallelism misalignment between guide plate is less than 0.05mm,and for mould,less than 0.03mm,much lower than the industry average value. So our forming product size will be more precision, bottom will be more perfect.

3. Connection mechanism adopts wear resisting steel bushing, bears more weight, rotates more precise. And the symmetrical swing ensures the parallelism of machine running, to avoid four pillars transverse abrasion, and make the machine more long-life.

4. The assisting mechanism of changing mould, which is equipped with the sliding rail and supporting bar, to realize quick changing, save more time and labor.

5. Driven by high-power servo motor, super precision, high efficiency, and low noise.

6. The working theory is a combination of positive and negative pressure with assisting stretching in mould by some nylon plugs, which makes it have more powerful ability of making products.

7. The mould cavity has the cooling water inside, which expedites the cooling speed and makes it easy to demould.

8. The upper and lower station can adjust automatically, fast and more convenient.

the machine running.

Our Factory

Dongguan Dongxing Machinery Equipment Co., Ltd.

is a professional production enterprise specializing in the R & D, innovation and manufacture of various plastic molding machines. The company is located in Qiaotou town, Dongguan, adjacent to the airport, bus station and freight station. The traffic is very convenient.

Combined with more than 20 years' experience of plastic suction machine manufacturing, we developed a positive and negative pressure forming punching and stacking integrated machine with independent intellectual property rights. From a series of production processes such as charging, positive and negative pressure

molding, punching, trimming, stacking, counting, conveying, automatic recovery of materials,etc., a series of production processes are completed at once. The company specializes in producing positive and negative pressure thermoforming machine, cup making machine, servo driven high-speed molding machine and ordinary high-speed molding machine.

Customer visits to our factory and our exhibitions

Certifications

Packing Details

Plastic Thermoforming Machine packaging

1,Standard export wooden case with plastci film.

2,as customer's request.

3.1*40HC

Application

This machine is suitable for the production of highly demanding food packaging products:

cup lids, freshness trays, moon cake trays, disposable fast food boxes, disposable food boxes, instant noodle bowl lids, milk tea lids, coffee cup lids, beverage cups, ice cream cups, jelly cups, packaging boxes, plastic packaging containers for daily necessities, medical plastic packaging, wine packaging and plastic packaging for electrical appliances.

Applicable materials: PP, PS, PET, CPET, PVA, OPS, PLA, etc.

FAQ

Q1: Are you a factory or trading company?

We are a factory, and we are a professional plastic thermoforming machinery and equipment manufacturer dedicated to the research and development。

Q2. why should you buy from us not from other suppliers?

Combined with more than 20 years' experience of plastic suction machine manufacturing, we developed apositive and negative pressure forming punching and stacking integrated machine with independentintellectual property rights.

Combined with more than 20 years' experience of plastic suction machine manufacturing, we developed apositive and negative pressure forming punching and stacking integrated machine with independentintellectual property rights.

Q3: How long is the warranty period?

13months calculated from the date of shipment from our factory.During warranty period, except the artificial factor, the spares are free to maintenance, beyond the warranty time, the buyer needs to pay the spare charge and shipping cost.

Q4: How to install the machine?

We will send technician to your factory to install the machine, and teach your workers to use it. You pay all related costs, including visa charge, double-way tickets, hotel, meals, and technician salary.

Q5:How can we guarantee quality?

W

e will test repeatedly before shipment until we achieve customer satisfaction.

Hot Searches