- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

widely, in air plane, oil

-

Grade:

-

inconel 600

-

Ni (Min):

-

68%

-

Model Number:

-

inconel 600

-

Brand Name:

-

Raymond

Quick Details

-

Resistance (μΩ.m):

-

standard

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

965

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

widely, in air plane, oil

-

Grade:

-

inconel 600

-

Ni (Min):

-

68%

-

Model Number:

-

inconel 600

-

Brand Name:

-

Raymond

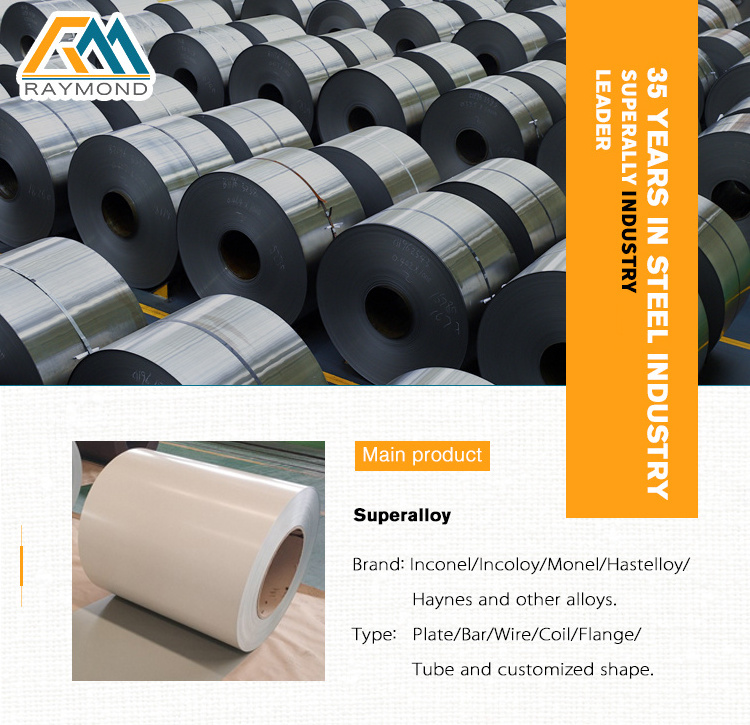

1.Introduction

Inconel 600 alloy is ni-cr-iron base alloy solid solution strengthening, has good resistance to high temperature corrosion and oxidation resistance, good cold and hot machining and welding performance,under 700 ℃ has a satisfactory heat intensity and high plasticity.

2.Chemistry

Some chemical properties of Inconel 600 include:

|

|

N

|

Cr

|

Fe

|

C

|

Mn

|

Si

|

Cu

|

AL

|

Ti

|

|

MIN

|

72

|

14

|

6

|

|

|

|

|

|

|

|

MAX

|

|

17

|

10

|

0.15

|

1.0

|

0.5

|

0.05

|

0.3

|

0.3

|

3.Nearly brand

GH3600, GH600 (China), NC15Fe (France), w. nr.2.4816, NiCr15Fe (Germany), NA14 (UK)Inconel600,

UNS NO6600(us) NiCr15Fe8(ISO)Inconel600, 55din /EN 2.4816, ASTM b600-168, ASME

UNS NO6600(us) NiCr15Fe8(ISO)Inconel600, 55din /EN 2.4816, ASTM b600-168, ASME

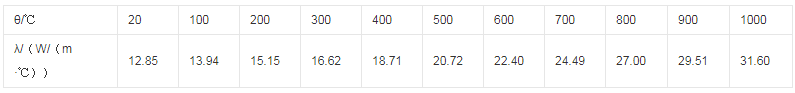

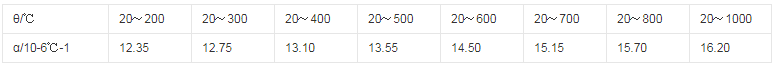

4.Property

heat conductivity

electrical resistivity

5.Inconel 600 has the following features:

1. Good corrosion resistance of reducing, oxidizing and nitriding media.

2. Good stress corrosion crackingresistance at room temperature and high temperature.

3.Good resistance to dry chlorine gas and hydrogen chloride gas corrosion.

4. It has good mechanical properties at minus, room temperature and high temperature.

5. Has the very good creep rupture strength, recommended above 700 ℃ working environment.

2. Good stress corrosion crackingresistance at room temperature and high temperature.

3.Good resistance to dry chlorine gas and hydrogen chloride gas corrosion.

4. It has good mechanical properties at minus, room temperature and high temperature.

5. Has the very good creep rupture strength, recommended above 700 ℃ working environment.

Hot Searches