- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50Hz

-

Power:

-

40KW

-

Dimension(L*W*H):

-

1600mm*1100*1800

-

Weight:

-

850 kg

-

Function:

-

Oil Filtration

-

Product name:

-

Waste Transformer Oil Filtration System

-

Raw material:

-

Stainless Steel

-

Heating method:

-

Burner

-

Capacity:

-

5-300Tons

-

Application:

-

Transformer Oil Purification

-

Suitable Oil:

-

Lube Oil Hydraulic Oil

-

Advantages:

-

Environmentally Friendly

Quick Details

-

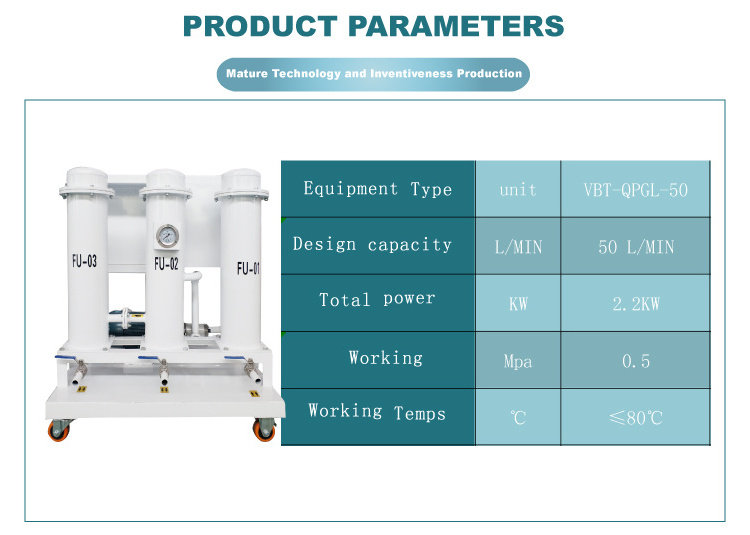

Flow:

-

3000L/H

-

Place of Origin:

-

Chongqing

-

Brand Name:

-

Vbolt

-

Voltage:

-

380V/50Hz

-

Power:

-

40KW

-

Dimension(L*W*H):

-

1600mm*1100*1800

-

Weight:

-

850 kg

-

Function:

-

Oil Filtration

-

Product name:

-

Waste Transformer Oil Filtration System

-

Raw material:

-

Stainless Steel

-

Heating method:

-

Burner

-

Capacity:

-

5-300Tons

-

Application:

-

Transformer Oil Purification

-

Suitable Oil:

-

Lube Oil Hydraulic Oil

-

Advantages:

-

Environmentally Friendly

Product Description

Three- Stage Vacuum Used Oil Purifier

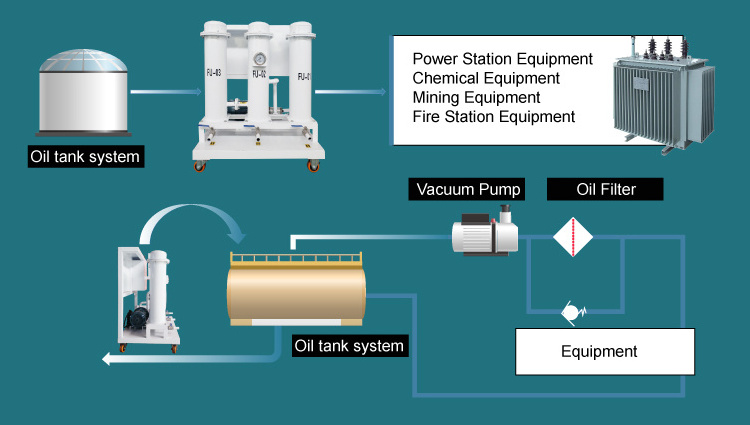

1) For maintenance of large scale power substation transformers, rapid and deep treatment of

new transformer oil, imported insulation oil. As well as vacuum filtering and purifying of mutual

inductor oil, capacitor oil, refrigerator oil.

2) Especially suitable for purifying of large scale power transmission units higher than 110KV and

transformers of main state grid.

itis three stage vacuum transformer oil purifier, which contain vacuum pump and roots pump. We can

do more big capacity of machine, and the smallest one is biggest one is more than

30,000L/H. The machine is adopted the rustproof and moisture film and wood cases packages. We can

take special order for you, like the machine face, color, weight, size, filter precision, filter numbers, spare

parts, oil specification tester, etc.

Application

Feature show

No.1

Our commitment to fuel cleanness

We guaranteed to Provide Clean Oil Fitration Systems ,adopt Duplex stereo-evaporation technology and G technology,adopt German 3UG3 phase relay,Impurity elimination technology that combines nanomolecules with mesh filtration.

Strong ability to remove impurities: high β-value precision filter material, multi-stage filtration step by step encryption, to remove fine particles in the oil. The filter element has large volume and large dirt holding capacity. Long service life, and equipped with automatic detection function of filter element pollution degree.

No.2

Low maintenance cost

Apply Trapezoidal spiral automatic back flushing system

Back flushable (cleanable) element reduces down time and frequency of

element replacements.

The usage life purifier is greatly prolonged by applying the advanced dielectric condensation devices

No.3

High efficiency

Adopt distinctive removing impurities technology that takes double FH trapezoidal network and absorbs by high polymer materials instead of the traditional simple network technology

Filter performance rated to remove 98% of all water and solid contaminants in a single pass. Various sizes to handle flow rates ranging from 10L/Min to300L/min

No.4

After sales

1. Service engineer to come to understand the needs of customers, help customers to design or improve the reasonable fluid pipeline scheme.

2. In accordance with customer demand to provide the best oil processing solutions, for customized design and customized production.

3. The company products and services more than "3 packets" standards of the state.

4. Engineers provide the installation instructions, hardware inspection, loading and running software debugging on site, and close cooperation with construction ,design units and customer ,Ideal with various aspects of operational equipment to ensure production safety equipment in time .

5. To provide comprehensive technical support, including system upgrade, equipment improvement, maintenance, technical consulting, etc.

6. Company engineers, operators and maintenance personnel for the user to provide different training courses, to ensure equipment use and maintenance of zero barriers at customer side.

Hot Searches