Explore More Products

- Product Details

- {{item.text}}

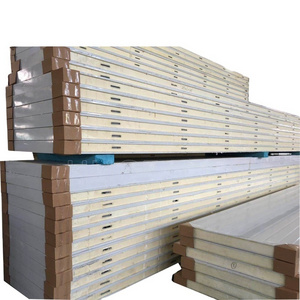

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SF

-

Model Number:

-

50/75/100/120/150

-

Product name:

-

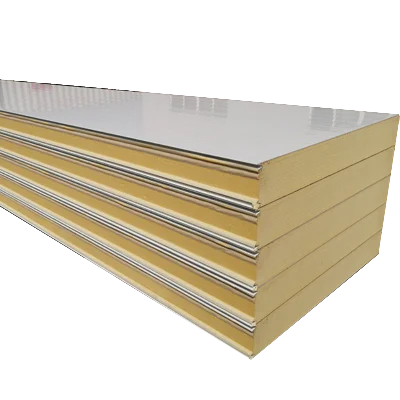

PU sandwich panel

-

Type:

-

sandwich panel

-

Color:

-

Customized

-

Core material:

-

PU PIR

-

Length:

-

As your requirement

-

Thickness:

-

50-200mm

-

Density:

-

50-120g

-

Features:

-

fierproof and waterproof easy to install

-

Surface material:

-

Color Coated PPGI Sheet

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Apartment

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SF

-

Model Number:

-

50/75/100/120/150

-

Product name:

-

PU sandwich panel

-

Type:

-

sandwich panel

-

Color:

-

Customized

-

Core material:

-

PU PIR

-

Length:

-

As your requirement

-

Thickness:

-

50-200mm

-

Density:

-

50-120g

-

Features:

-

fierproof and waterproof easy to install

-

Surface material:

-

Color Coated PPGI Sheet

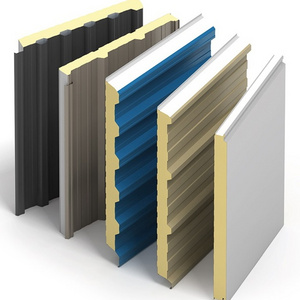

Product Description

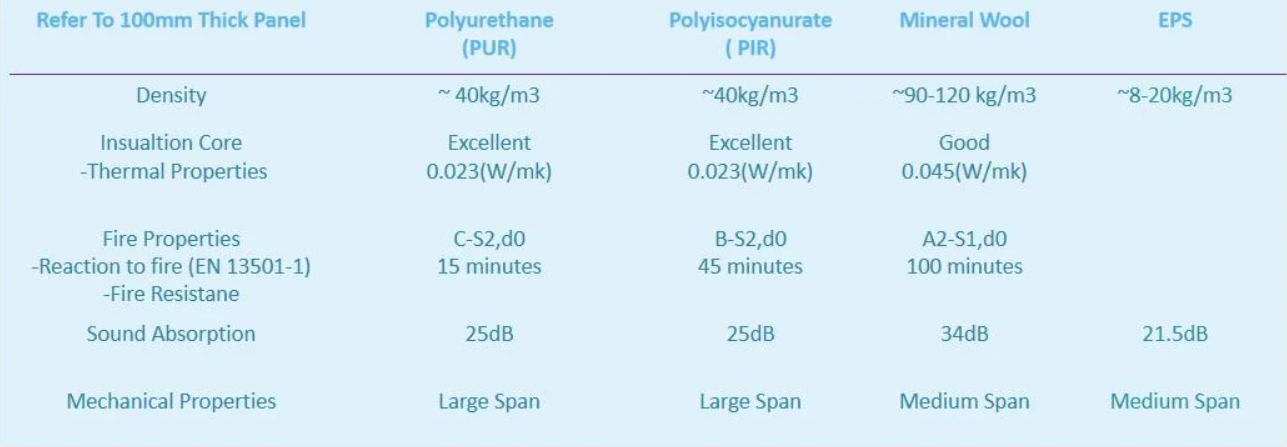

According to different core material, we offer Pur / Pir sandwich panel, Rockwool and Glasswool sandwich panel and EPS sandwich panel for your choice.

> Efficient Contruction:

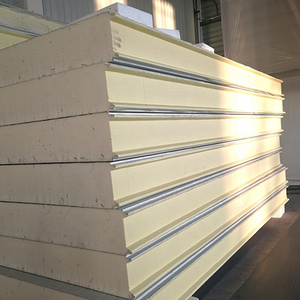

The light weight sandwich panels provide easy installation which can be triple faster than usual wood or concrete building. It can also has less affection from weather during construction. It allows large span, the supporting structure can be lighter.

> Perfect Energy Saving: Sandwich panel provides high thermal insulation by means of PUR, PIR, EPS and Mineral Wool insulation materials. It has lower U value and higher insulation capability .

> Environmental Friendly: Sandwich panels require less maintenance than concrete an brick structure; repainting is not required.It is more economical and environmental friendly.

> Safe, Durable and Reusable: Sandwich panels are light weight that are easy and safe to handle during construction. It can be easy assembly and disassembly.

> Versatility: Sandwich panels can be used for various applications, from all kinds of pre-fabricated steel buildings , warehouse, walk-in cold storgaes, cleanroom, farm, food processing plant and etc.

> Benefit and Value: Compare with traditional construction, sandwich panel are more economical in terms of labours, machines, time, maintenance.cost etc. It enables big saving in future operation costs.

> Perfect Energy Saving: Sandwich panel provides high thermal insulation by means of PUR, PIR, EPS and Mineral Wool insulation materials. It has lower U value and higher insulation capability .

> Environmental Friendly: Sandwich panels require less maintenance than concrete an brick structure; repainting is not required.It is more economical and environmental friendly.

> Safe, Durable and Reusable: Sandwich panels are light weight that are easy and safe to handle during construction. It can be easy assembly and disassembly.

> Versatility: Sandwich panels can be used for various applications, from all kinds of pre-fabricated steel buildings , warehouse, walk-in cold storgaes, cleanroom, farm, food processing plant and etc.

> Benefit and Value: Compare with traditional construction, sandwich panel are more economical in terms of labours, machines, time, maintenance.cost etc. It enables big saving in future operation costs.

Propertis Of Sandwich panel

|

Product Name

|

Pu Cold Room Panel

|

|

Core Thickness

|

50mm 60mm 80mm 100mm 120mm 150mm 180mm 200mm

|

|

Density of core

|

38-42kg/m3

|

|

Steel Plate Thickness

|

0.4-0.8mm

|

|

Metal Sheet

|

Color Coated Steel Sheet / Stainless steel plate

|

|

Galvanized layer of steel plates

|

Exterior plate and Inner plate: Aluzinc or Zinc coating

|

|

Panel Length

|

According to customers' request

|

|

Width

|

1000mm / 1135mm

|

|

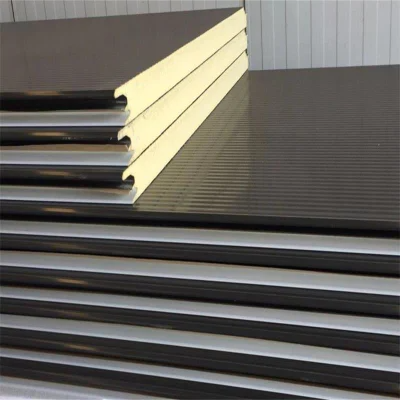

Product Name

|

Roof Sandwich Panel

|

|

Core Thickness

|

40mm / 60mm / 100mm / 120mm

|

|

Density of core

|

38-42kg/m3

|

|

Steel Plate Thickness

|

0.4-0.7mm

|

|

Metal Sheet

|

Color Coated Steel Sheet

|

|

Galvanized layer of steel plates

|

Exterior plate and Inner plate: Aluzinc or Zinc coating

|

|

Panel Length

|

According to customers' request

|

|

Product Name

|

Wall Sandwich Panel

|

|

Core Thickness

|

40mm / 60mm / 80mm / 100mm / 120mm

|

|

Density of core

|

38-42kg/m3

|

|

Steel Plate Thickness

|

0.4-0.7mm

|

|

Metal Sheet

|

Color Coated Steel Sheet

|

|

Galvanized layer of steel plates

|

Exterior plate and Inner plate: Aluzinc or Zinc coating

|

|

Panel Length

|

According to customers' request

|

|

Width

|

1000mm

|

Strict Quality Control

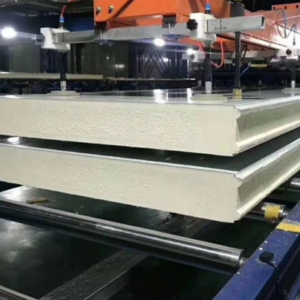

1: Sandwich panel testing equipment

With the exception of introducing the full set of Germany production line, relevant sandwich panel testing equipment are timely purchased in. Following parameter can be tested in the laboratory.

> mechanical performance of sandwich panels

> close-cell rate of foams

> fire resistance of foams

> heat transfer coefficient of foams

> stability of product dimensions all production are in strict accordance with current quality control standard in Europe.

With the exception of introducing the full set of Germany production line, relevant sandwich panel testing equipment are timely purchased in. Following parameter can be tested in the laboratory.

> mechanical performance of sandwich panels

> close-cell rate of foams

> fire resistance of foams

> heat transfer coefficient of foams

> stability of product dimensions all production are in strict accordance with current quality control standard in Europe.

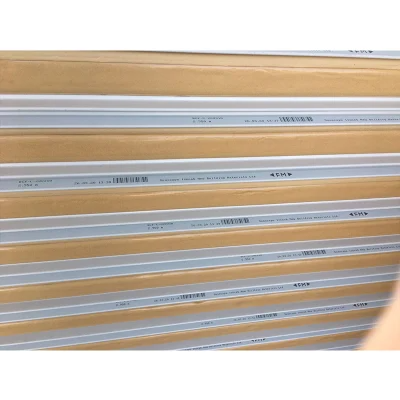

2: High-quality Materials

> steel sheets are produced by color-coated line(introduced from Nippon Steel), performances of which are all conforming with European standard.

> Foam mateirals are supplied by the world top four PUR suppliers such as Bayer, DOW, Huntsman .Sunscape has also established long-term cooperative mechanism with them to make efforts for the development of PUR sandwich panels.

> steel sheets are produced by color-coated line(introduced from Nippon Steel), performances of which are all conforming with European standard.

> Foam mateirals are supplied by the world top four PUR suppliers such as Bayer, DOW, Huntsman .Sunscape has also established long-term cooperative mechanism with them to make efforts for the development of PUR sandwich panels.

Project Case

Recommend Products

Hot Searches