- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Blind flange

-

Flange Type:

-

WN

-

Color:

-

Customer's Requests

-

Pressure:

-

PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

-

OEM:

-

Accept

-

Type:

-

Round Flange

-

Technics:

-

Forged Casting

-

Flange material:

-

Carbon Steel / Q235 / Stainless Steel

-

Coating:

-

black paint, yellow transparent paint

-

Packing:

-

Wooden case or pallet

-

Transportation:

-

Bulk Vessel

Quick Details

-

Standard:

-

ANSI, MSS, AWWA, DIN, UNI, JIS, BS, EN1092, GOST, SABS

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

TIANYI SUNS

-

Model Number:

-

Blind flange

-

Flange Type:

-

WN

-

Color:

-

Customer's Requests

-

Pressure:

-

PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

-

OEM:

-

Accept

-

Type:

-

Round Flange

-

Technics:

-

Forged Casting

-

Flange material:

-

Carbon Steel / Q235 / Stainless Steel

-

Coating:

-

black paint, yellow transparent paint

-

Packing:

-

Wooden case or pallet

-

Transportation:

-

Bulk Vessel

ANSI B16.5 Stainless Steel SS Weld Neck Pipe Flange Supplier

Products Description

Weld Neck Flange

is flanges that designed to be joined to a piping system by butt welding. This kind of flange include lots of specification.

Weld Neck Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high-stress applications. The necks, or hubs, transmits stresses to the pipeline.

The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck Flange. The bore of Weld-Neck flange matches bore of the pipeline, reducing turbulence and erosion.

Weld Neck Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high-stress applications. The necks, or hubs, transmits stresses to the pipeline.

The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck Flange. The bore of Weld-Neck flange matches bore of the pipeline, reducing turbulence and erosion.

|

Size

|

1/2″ to 48″ DN10~DN5000

|

|

Flange Standards

|

ANSI, MSS, AWWA, DIN, UNI, JIS, BS, EN1092, GOST, SABS

|

|

Pressure Rating

|

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

|

|

ANSI B16.5

|

6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64

|

|

JIS

|

5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K

|

|

UNI

|

6Bar 10Bar 16Bar 25Bar 40Bar

|

|

EN

|

6Bar 10Bar 16Bar 25Bar 40Bar

|

|

Coating

|

Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized

|

|

Process

|

Forged

|

|

Test Certificates

|

Raw Materials Certificate

100% Radiography Test Report Third Party Inspection Report, etc |

|

Production technique

|

Forged, Heat treated and machined

|

|

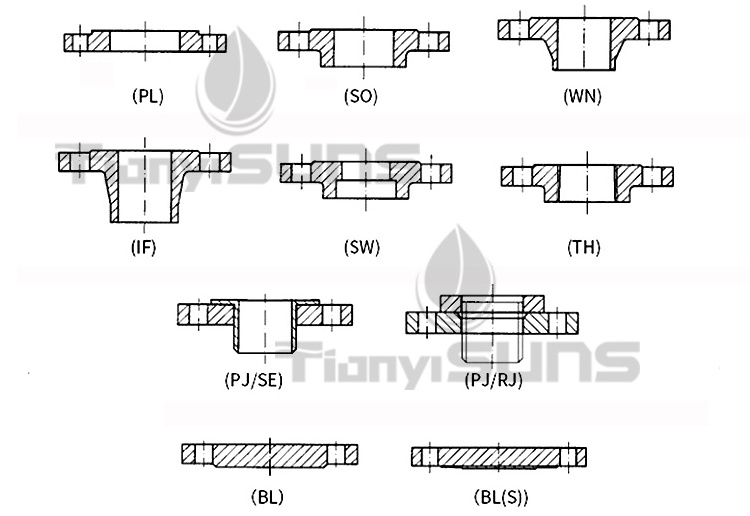

Types

|

Weld Neck, Blind, Slip-On, Socket-Weld, Threaded, Orifice, Spectacle Blinds

|

|

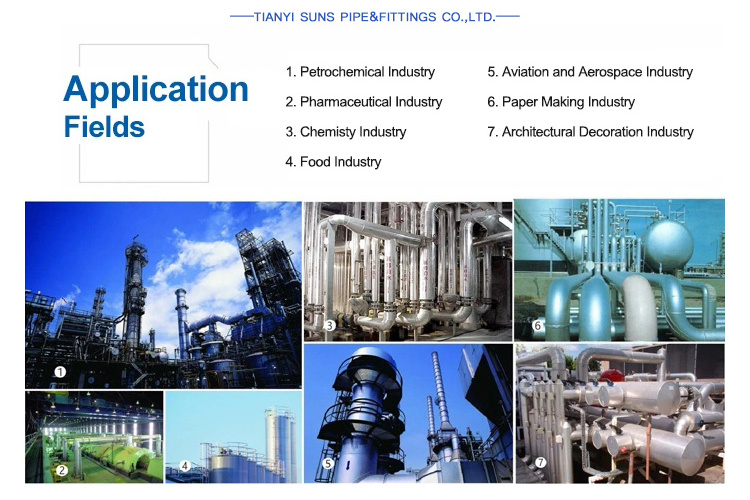

Uses & application

|

Bitumen upgraders.

Heavy oil refineries.

Nuclear power (mostly seamless). Petrochemicals and acids. |

Details Images

SEVERAL TYPES

Production process

FACTORY DISPLAY

Testing

Product packaging

Recommend Products

Hot Searches