- Product Details

- {{item.text}}

Quick Details

-

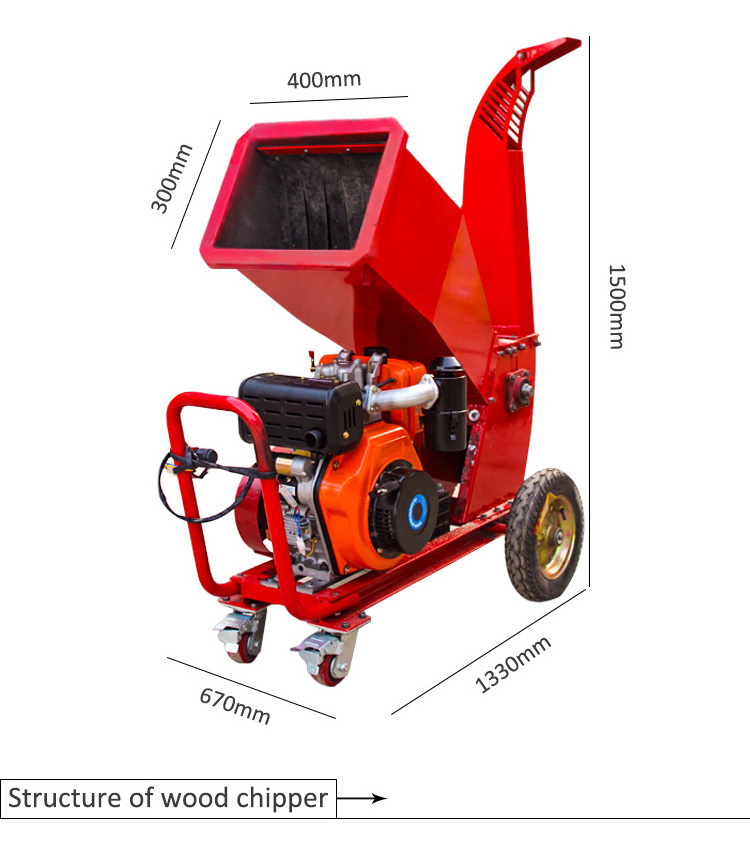

Dimension(L*W*H):

-

1330x670x1500mm

-

Weight:

-

180 KG

-

Wood Inlet Dimension:

-

400x300mm

-

Capacity:

-

1-2t/h

-

Power:

-

15hp

-

Name:

-

firewood processor

-

Engine type:

-

diesel engine

-

Engine model:

-

186F

-

Usage:

-

Wood Shredder Cutting Wood Branch

-

Fuel tank Capacity (L):

-

6.5L

-

Feature:

-

High Efficiency Low Cost

Quick Details

-

Use:

-

Chipping Wood

-

Place of Origin:

-

China

-

Brand Name:

-

YULE

-

Dimension(L*W*H):

-

1330x670x1500mm

-

Weight:

-

180 KG

-

Wood Inlet Dimension:

-

400x300mm

-

Capacity:

-

1-2t/h

-

Power:

-

15hp

-

Name:

-

firewood processor

-

Engine type:

-

diesel engine

-

Engine model:

-

186F

-

Usage:

-

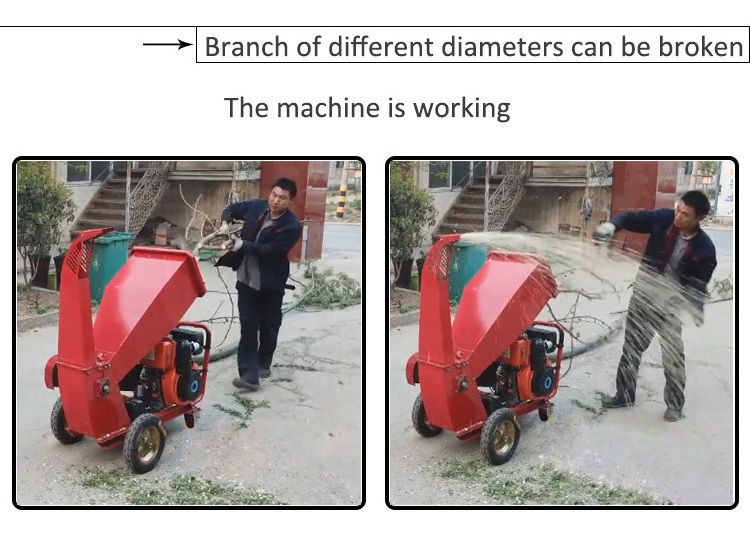

Wood Shredder Cutting Wood Branch

-

Fuel tank Capacity (L):

-

6.5L

-

Feature:

-

High Efficiency Low Cost

Fire wood processor firewood processor

The wood chipper machine is mainly made up of its own body, a feed inlet device, a cutterhead device, a discharging device,and an auxiliary fan.The whole set of equipment is simple in structure,sturdy and durable (with a unique and high quality cutterhead), stable operation, high quality and efficiency.

|

Machine Dimension |

1330*670*1500mm |

|

Caoacity |

1-2t/h |

|

Engine type |

D iesel engine |

|

Engine model |

186F |

|

Start type |

E lectric start |

|

Fuel tank Capacity(L) |

6.5L |

|

Power |

15 hp |

|

Color |

Customized |

|

Wood inlet dimension |

400*300mm |

|

Weight |

180kg |

The wood chipper advantages:

Powerful, large-diameter design is more suitable for raw materials delivery, easy to move freely.

Usage:

1.The small chips made by the wood chipper can be used for animal bedding, for the forestry and soil protecting, for new energy making, for compost and for charcoal.

2.Some customers use their colored garden waste chips, cover the soil and made the garden beautiful.Some of them use the garden waste chips in the fireplace

More types of wood chipper

Pre-sale services

1. 24 hours online, Your inquiry will be reply quickly.

2. Help you choose the most suitable machine

3. Introduce details of the machine for you with pictures or video.

In-sales services

1. Customized machine according to your request.

2. Test and inspect every machine with strict quality control.

3. Packing with standard export wooden box after you confirm the machine

After-sales services

1. Offer the professional engineer help you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality guarantee for two years. Free repair for quality problem during these years.