- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.6mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ST

-

Voltage:

-

380V 50hz 3 phases or as required

-

Dimension(L*W*H):

-

7.2*1*1.5m

-

Weight:

-

4500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Hot Product 2021

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Main frame:

-

300H Steel

-

Plc:

-

DETLA

-

Thickness:

-

0.3-0.6mm

-

Color:

-

Client's Request

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Material:

-

Color Steel Galvanized Plate

-

Decoiler:

-

5T Manual Decoiler

-

Roller material:

-

45#steel Chrome Plated

Quick Details

-

Type:

-

roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10m/min

-

Rolling thinckness:

-

0.3-0.6mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ST

-

Voltage:

-

380V 50hz 3 phases or as required

-

Dimension(L*W*H):

-

7.2*1*1.5m

-

Weight:

-

4500 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

Hot Product 2021

-

Usage:

-

Steel Construction

-

Raw material:

-

PPGI PPGL GI GL

-

Main frame:

-

300H Steel

-

Plc:

-

DETLA

-

Thickness:

-

0.3-0.6mm

-

Color:

-

Client's Request

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Material:

-

Color Steel Galvanized Plate

-

Decoiler:

-

5T Manual Decoiler

-

Roller material:

-

45#steel Chrome Plated

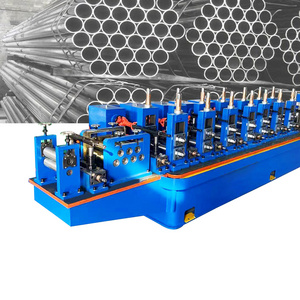

(1). Brief Introduction

The Roof tiles made by oursingle layer roofing roll forming machine for roof panel have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands,

ancient architectures and modern villas.

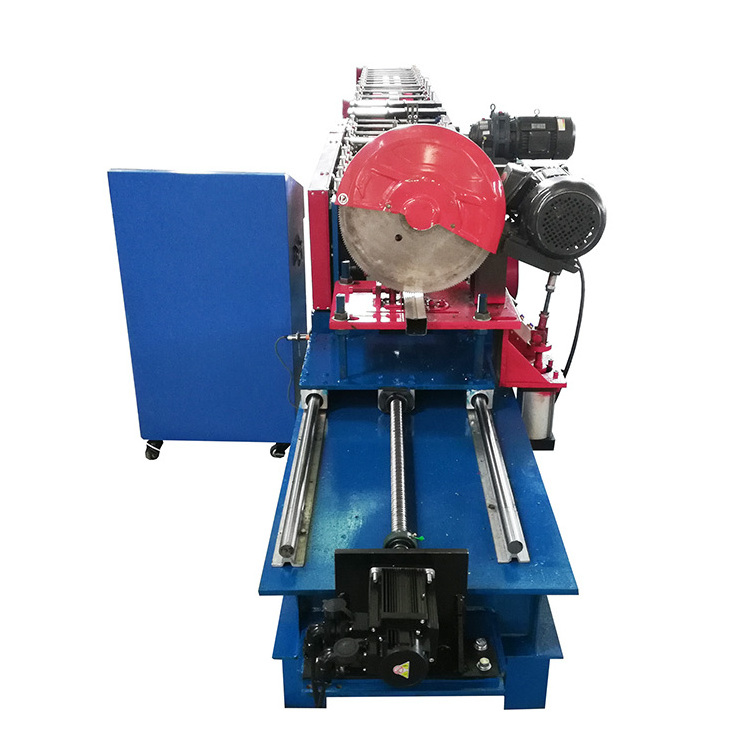

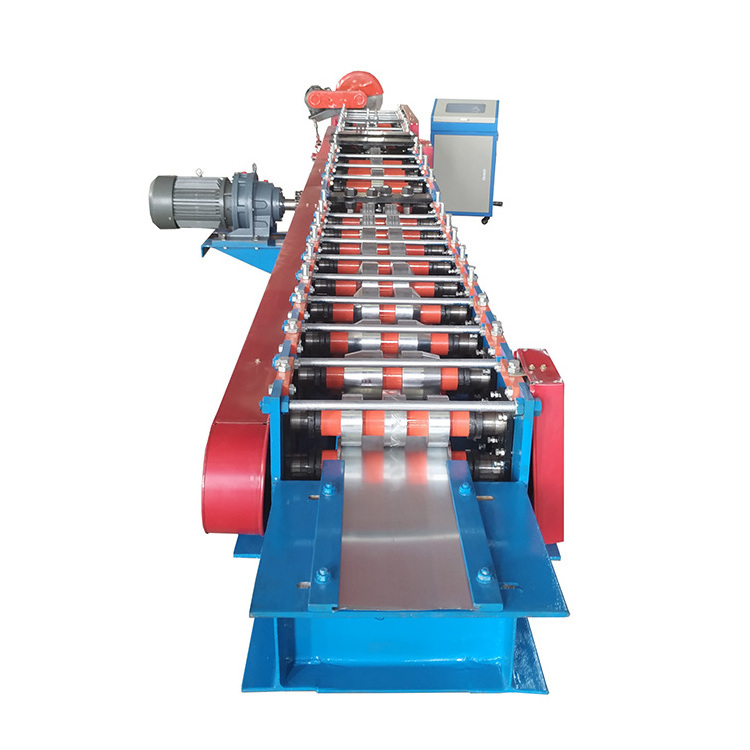

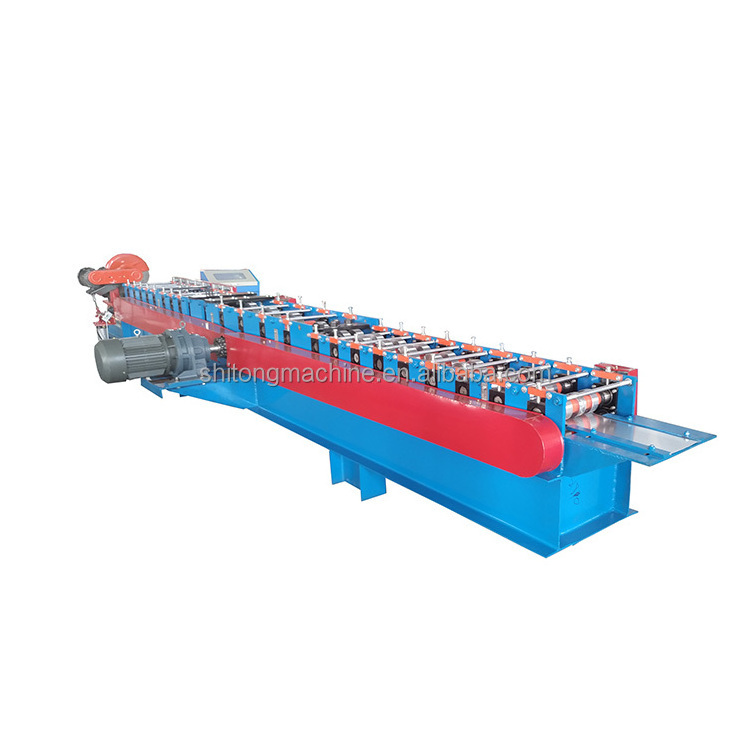

2). Working Flow of Metal Roofing Sheet Corrugating Iron Sheet Roll Forming Making Machine,Cold Galvanizing Line

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter

(3) .Technical Detail

A Sheet Specifications

|

1 |

Coil Type |

PPGI GI |

|

2 |

Thickness |

0.3-0.6mm |

|

3 |

Yield stress |

Q235 |

B Components Details

|

Roller Material |

High grade 45# steel. Hard chrome plating, 0.05mm. |

|

Main Frame |

300# steel. More stable and no shaking. |

|

Middle Plate |

16mm. We use thicker plates to ensure stability of our products. |

|

Forming Steps |

14 rollers |

|

Shaft Material |

Φ60 mm, high grade 45# steel. |

|

Treating process: tempering- finish turning, high rigidity, hard to deform. |

|

|

Cutting Blade Material |

Cr12, hardness HRC60-62. |

|

Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C. Electric Components

|

Suitable Power |

380V, 50 Hz, 3 phase or according to your need. |

|

Screen |

7 inch touch screen, easy to operate. |

|

PLC |

Delta DVP 14ES |

|

well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

|

|

Frequency Converter |

Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

|

Length Measurement Device |

Omron, made in Japan. |

|

It features with high accuracy and stability. |

|

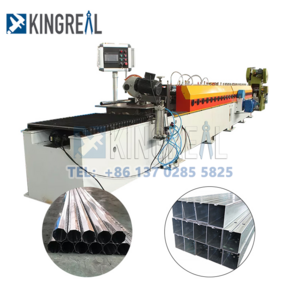

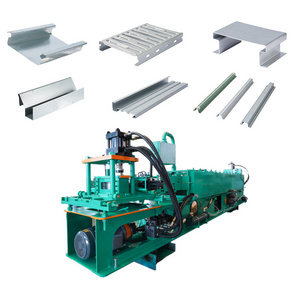

4. We have other Roll Forming Machine for your reference |

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,

shutter door machine, floor decking machine and other associated equipment.

Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

|

6. We provide shipping service for Roll forming machines |

1. Machines need one 20 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

|

7. Terms and aftersale service |

1.Payment Term: 30% paid by T/T as down payment, the rest 70% after inspection by buyer in seller’s factory while before delivery. After finished production, we will inspect the machine and inform the buyer, the buyer send person to inspect goods, then payoff the whole payment before shipping.

2.Delivery Time: We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

3.After sale Service: We could send technician to your country to install machine if you need. The buyer need to pay for all the cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.Warranty: 24 months

During the warranty, the replaceable parts are free, but the buyers need to pay for the shipping . We will also provide you instruction manual to show you how to operate the machines.