- Product Details

- {{item.text}}

Quick Details

-

Wheel Size(mm):

-

500

-

Surface Roughness(μm):

-

0.63 μm

-

Table Size(mm):

-

400*1000

-

Year:

-

2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

hicas

-

Voltage:

-

380V 50HZ 3PH

-

Dimension(L*W*H):

-

4400*2400*2800

-

Weight (KG):

-

6200

-

Power (kW):

-

22

-

Wheel size O.D:

-

500mm

-

Wheel size I.D:

-

203mm

-

Width:

-

35~100mm

-

Distance from dressing spindle to table:

-

45mm

-

Electrical equipment total capacity:

-

40kVA

-

Overall dimensions:

-

4400*2400*2800

-

Spindle motor Power:

-

22 kw

-

Rotation speed:

-

0~1500

-

Size of working table:

-

400*1000

-

Max table load capacity:

-

1000

Quick Details

-

Grinding Length(mm):

-

1000

-

Table Travel (X) (mm):

-

1050

-

Table Travel (Y) (mm):

-

400

-

Wheel Size(mm):

-

500

-

Surface Roughness(μm):

-

0.63 μm

-

Table Size(mm):

-

400*1000

-

Year:

-

2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

hicas

-

Voltage:

-

380V 50HZ 3PH

-

Dimension(L*W*H):

-

4400*2400*2800

-

Weight (KG):

-

6200

-

Power (kW):

-

22

-

Wheel size O.D:

-

500mm

-

Wheel size I.D:

-

203mm

-

Width:

-

35~100mm

-

Distance from dressing spindle to table:

-

45mm

-

Electrical equipment total capacity:

-

40kVA

-

Overall dimensions:

-

4400*2400*2800

-

Spindle motor Power:

-

22 kw

-

Rotation speed:

-

0~1500

-

Size of working table:

-

400*1000

-

Max table load capacity:

-

1000

Product Description

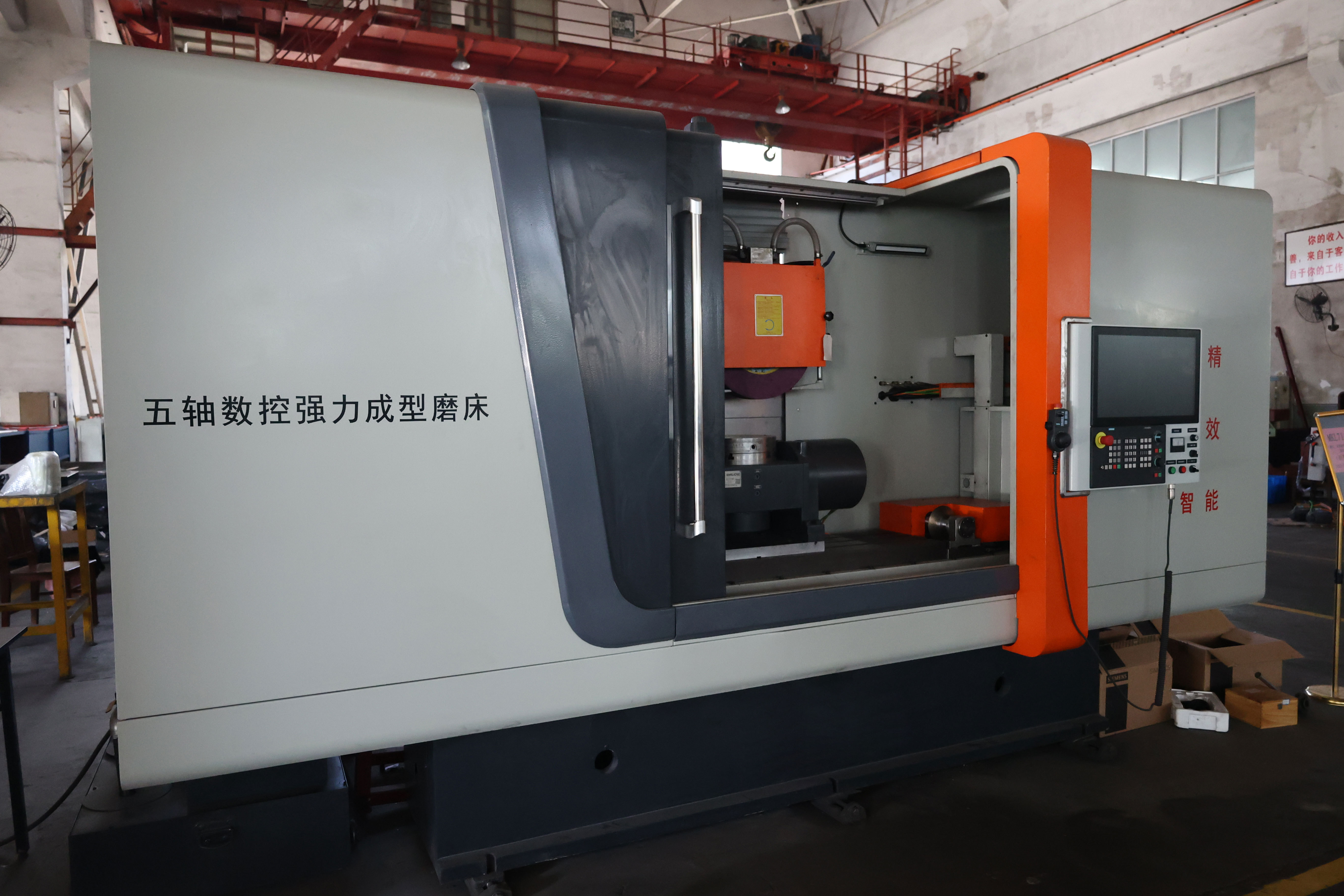

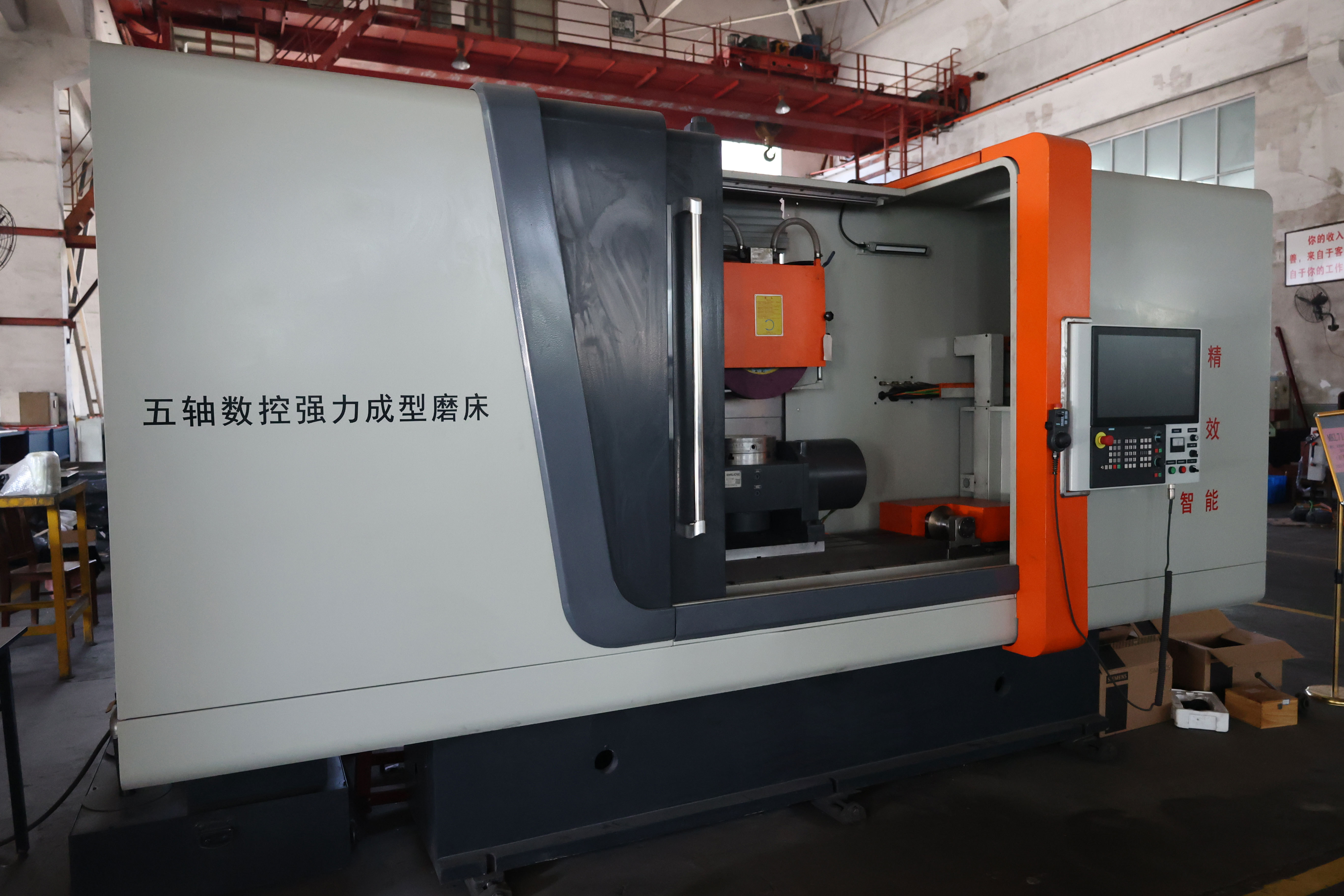

Main Structure

1>

The machine is CNC creep feed profile grinding machine, it adopts colume waist mobile structure. Horizontal guide rail is placed on both sides of the colume, which runs smoothly and work with high precision. The machine is suitable for multi direction,convex surface,concave surface ,arc surface and other parts surface.

2>

The machine has five CNC axes, X,Y,Z for linear axis, these three axes adopt linear guide rail and ball screw structure. Axis A adopts floating nut structure with high speed screw, with novel design, advanced technology, sensitive feed and high machining precision,which has the functions of forming grinding and surface grinding.Axis A is inclined axis, axis B is rotary axis and equipped with HEIDENHAIN encoder, which with high repetition accuracy.

3>

Unique anti-collision grinding head structure, spindle accuracy and stability, standard Siemens 840D/828D numerical control system. It can be longitudinal movement of the table, grinding head vertical feed, column transverse feed, grinding wheel spindle and dressing spindle for separate control or linkage; With linear interpolation and circular interpolation and other functions,can realize automatic cycle grinding, positioning accuracy and repeated positioning accuracy.

4>

Grinding wheel can be dressed by diamond roller, or by diamond pen and diamond disc through axis Y and axis Z linkage dressing with high precision.

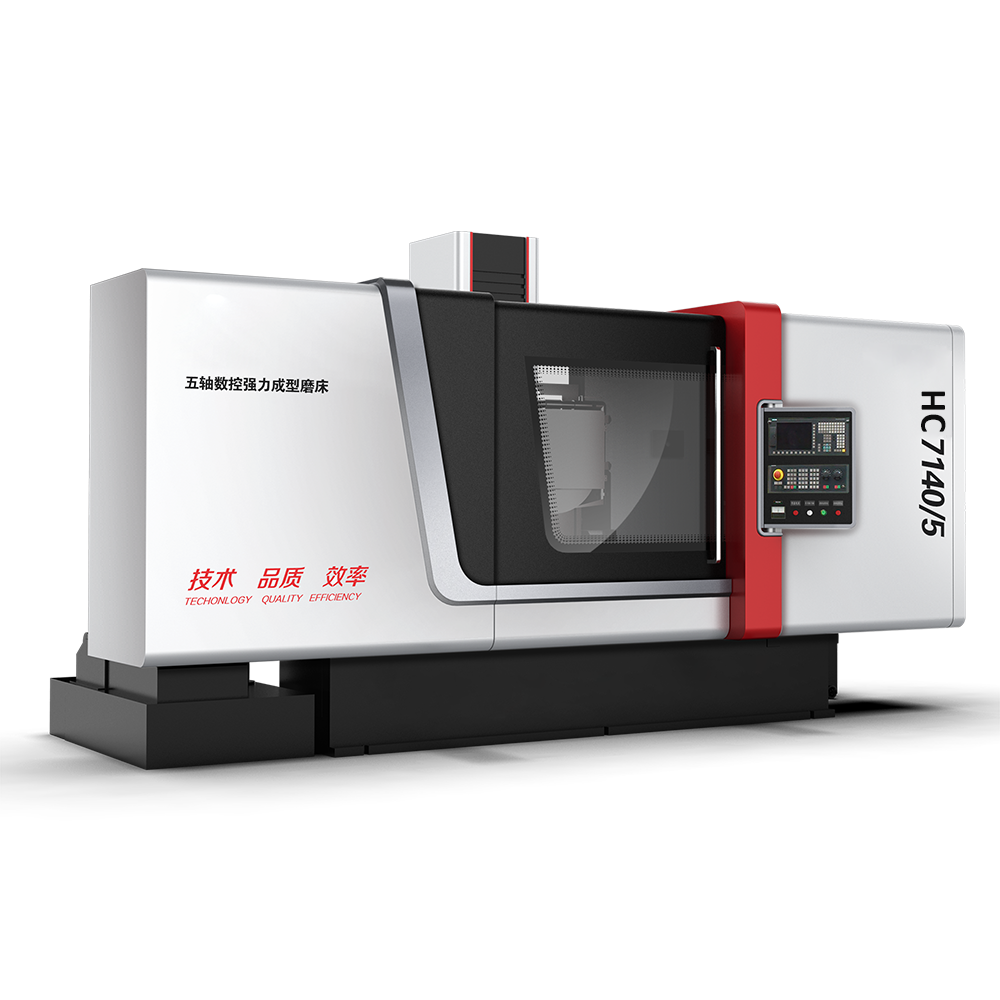

Specification

|

Model Number

|

HC7140/5

|

|

Size of working table (W*L)

|

400×1000MM

|

|

Max table load capacity (Including eletromagnetic chuck and turntable)

|

1000KG

|

|

axis-X Max. stroke

|

1050MM

|

|

axis-X Speed of movement

|

0.02~15M/MIN

|

|

axis-X Setting unit

|

0.001MM

|

|

axis-Y Distance from spindle center to tabel

|

200~950MM

|

|

axis-Y Speed of movement

|

0.01~2M/MIN

|

|

axis-Y Setting unit

|

0.001MM

|

|

axis-Z Column transverse travel

|

400MM

|

|

axis-Z speed of travel movement

|

0.01~3 m/min

|

|

axis-Z Setting unit

|

0.001 mm

|

|

axis- A Angle range

|

±60°

|

|

axis- A Min.feed

|

0.001°

|

|

axis-B Angle range

|

0°~360°

|

|

axis-B Min.feed

|

0.001°

|

|

Spindle motor Power

|

22KW

|

|

Spindle motor Rotation speed

|

0~1500rpm

|

Detailed Images

Certifications

Packing&Shipping

Hot Searches