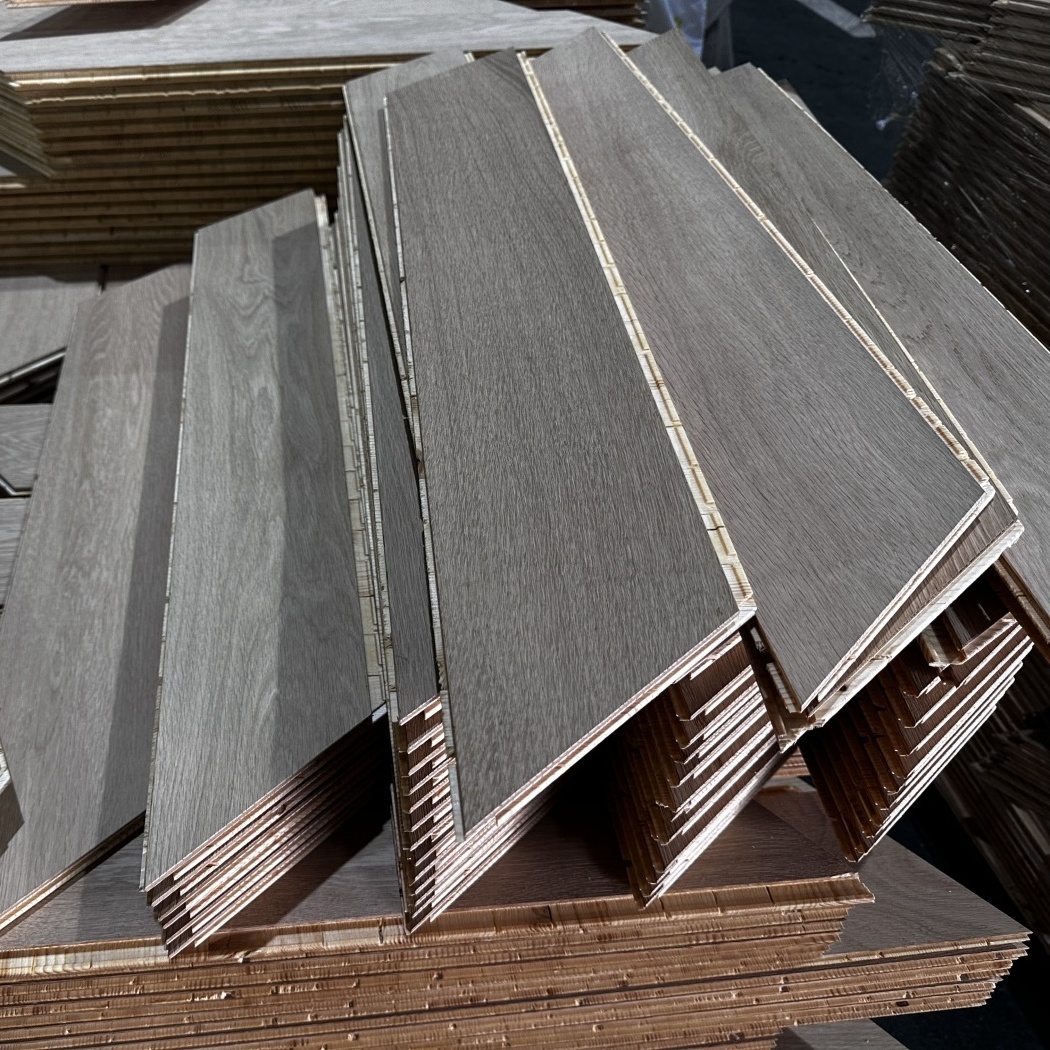

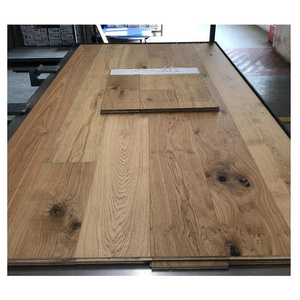

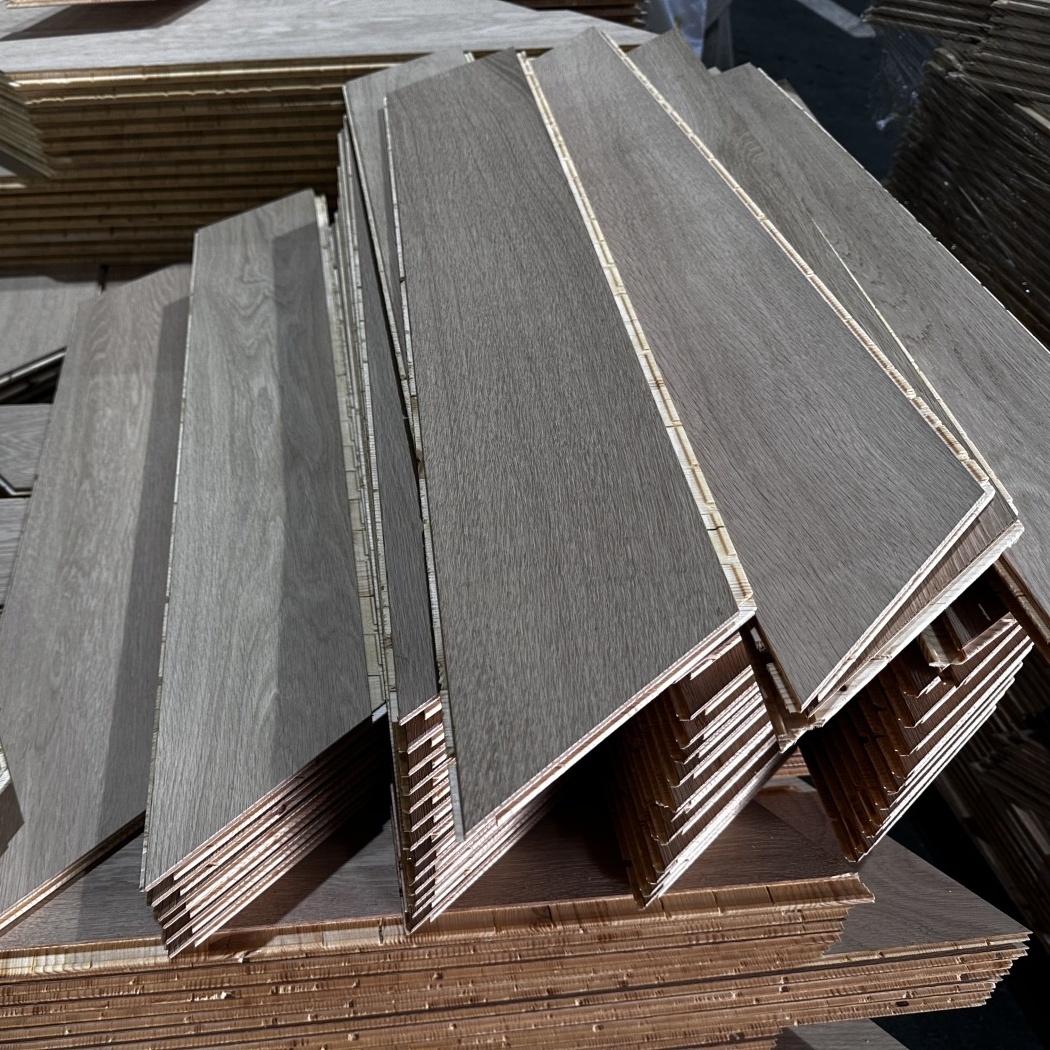

2G system of European oak hardwood flooring brushed engineered oak timber flooring chevron oak with natural oiled for indoor

FOB Reference Price:

Get Latest Price

≥2 Square meters

US $48

≥100 Square meters

US $43

≥1600 Square meters

US $38

≥100000 Square meters

US $33

Free Inquiry

Customized Request

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

indoor

-

Design Style:

-

Modern

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kelai

-

Model Number:

-

15/4X120X600mm

-

Type:

-

Engineered wood floor

-

Pattern:

-

chevron

-

Grade:

-

AB

-

Surface:

-

Brush

-

coating:

-

UV lacquered

-

Connect:

-

2G

-

Bevel:

-

Mirco bevel

-

MOQ:

-

100 Sq Meter

-

Certificates:

-

FSC

-

MOISTURE CONTENT:

-

8%-10%

Quick Details

-

Engineered Wood Flooring Type:

-

Multilayer Engineered Wood Flooring

-

Technics:

-

Brushed

-

Installation Type:

-

T&G

-

Application:

-

indoor

-

Design Style:

-

Modern

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kelai

-

Model Number:

-

15/4X120X600mm

-

Type:

-

Engineered wood floor

-

Pattern:

-

chevron

-

Grade:

-

AB

-

Surface:

-

Brush

-

coating:

-

UV lacquered

-

Connect:

-

2G

-

Bevel:

-

Mirco bevel

-

MOQ:

-

100 Sq Meter

-

Certificates:

-

FSC

-

MOISTURE CONTENT:

-

8%-10%

Product Description

|

Species

|

Oak

|

Pattern

|

Chevron

|

|

Construction

|

Multilayer Engineered wood flooring

|

Top Veneer Thickness

|

4MM

|

|

Moisture Content

|

8%-10%

|

Thickness

|

15MM

|

|

Grade

|

ABCD

|

Width

|

120 MM

|

|

Surface Finish

|

Unfinished

|

Length

|

600MM

|

|

Surface Texture

|

Wire Brushed

|

Coating

|

UV lacquered

|

|

Bevel

|

Micro Bevel

|

Connect system

|

2G

|

Detailed Images

A contemporary look with a classical geometrical composition and layout given by a shadowing effect. Playing with a paint applied with a gradient we create shadows for a

three-dimensional impact. Black - tinted oak and washed out, like a Denim, and dyed in red. A special process conceived as a treatment on fabric, that gives to the floor a strong and sharp chromatic intensity. The camouflage patterns inspired by the traditional military uniforms is obtained with a special printing technique. This light printing let the natural wood’s texture visible to enrich the effect of two patterns overlapped creating a non uniform colour effect keeping wood’s qualities unchanged.

Material Description

Versailles solid wood parquet flooring is the product of a special and ancient production method, which is completely different

from the traditional production of Mosaic wood or wood flooring .

from the traditional production of Mosaic wood or wood flooring .

Versailles parquet flooring is known as the most popular solid wood parquet flooring, because it has complicated process and

retains unique parquet structure, although the production is complicated and the process is complicated. But the end result is a wood floor that, like a craft, Versailles w ood flooring that will last a long time.

retains unique parquet structure, although the production is complicated and the process is complicated. But the end result is a wood floor that, like a craft, Versailles w ood flooring that will last a long time.

More colors for reference :

Parquet Hardwood Floor collection :

Artisans created elaborate designs by cutting and fitting small geometric pieces of wood together, one at a time, and then gluing them to the floor.

Our parquet floors are an astonishing contrast to the ordinary hardwood floor.

Our parquet floors are an astonishing contrast to the ordinary hardwood floor.

Quality Control

As a hardwood flooring supplier, Kelaiwood controls every stage of the production process, and our factory has strict quality control measures in place to guarantee the highest quality finished product every time.

All of kelai finished wood flooring are manufactured under strict production quality standards. Do our best. From the material to the Finished floor, each piece of board is processed through more than 40 processes. Each process is strictly checked by QC,controlled by certain production data, and tested by independent laboratory. To ensure performance meets or exceeds our internationally recognized standards,to ensure that only the best flooring reach our customers.

Boiling stripiping test

Measure test

Wear layer resistance test

Wood floor coating test

Color checking

Adhesive test

Packing&Shipping

Products:Kosso engineered wood flooring

Dimension:15/3X120X600 mm

Pcs/Sqm : 24pcs/ctn ;1.728

sqm/ctn

G.W.(kg/ctn) : 15KGS

Ctns/PLT:50-66 ctns/pallet ,

12 pallets

Dimension of PLT :

1230X1930mm;1030x1930mm

Ctns : 694 ctns/container

TAL SQM:1500 sqm/container

TAL G.W:14574 KGS

Related Products

Production Workshop

Kiln dry

The kiln facility helps control the moisture of Kelai boards during drying and is also a much faster process than drying outside in the open air. Different flooring species need different standards to dry. ( such as time, temperature, moisture, ect.)

Cold press

Gluing with a cold press is a less invasive process that won't damage the color or texture of venneer

We use the Germany FRANKLIN ,reaches E0 standard .

Repairing

After cold press, the boards are transmitted to repairing department for treatment of defects in which knots and crack. The extent of repair will depend on the type of cracks. Kelai workers will removed all loose particles around the crack, then patched and fixed with fluid epoxy resin such as 8 shades of epoxy resin.

Sawing to pieces

The boards are transmitted through sawing machine to produce individual pieces of flooring boards.

Sanding

Flooring boards are sanded to ensure similar thickness is maintained prior to T and G profiling. The boards are simultaneously checked for thickness during this process.

Notching

Sate-of-the-art manufaturing faclites HOMAG brand millig machine are able to utilize th

e latest breakthoughs in flooring technology of the highest quality.

Accurate Tongue & Groove and slight bevel can be achieved through equipment processing.The tolerance can be controlled in 0.05mm.

Brush

Wire brushed craft makes the wood grain of flooring more stereoscopic, glossy and beautiful. The depth of brushed: 0.5-1.0mm,1.5-2mm.

Coating line

Kelaiwood has three coating line which manufactured by Taiwan Fengchaou Machinery. The full-length lines is up to 130 meters.

Package

All finished kelai engineered hardwood floor, are covered by an Anti-wet plastic box as export standard. Flooring information labels will be marked on each carton.

Certificate

FAQ

Q1.What is engineered wood flooring?

A:Engineerd wood flooring is a type of flooring made up of multiple layers of wood, with a top layer of hardwood veneer. The layers are bonded together with adhesive, making the product more stable and resistant to moisture than solid hardwood flooring.

Q2.How is engineered wood flooring installed?

A: Engineered wood flooring can be installed using different methods, such as floating, glue-down, or nail-down installation. The installation method depends on the specific product and the subfloor.

Q3.What are the benefits of engineered wood flooring?

A:Engineered wood flooring offers several benefits over solid hardwood, including increased stability, resistance to moisture, and a more affordable price point. It can also be installed over concrete subfloors, which is not possible with solid hardwood.

Q4.How long does engineered wood flooring last?

A:The lifespan of engineered wood flooring depends on several factors, such as the quality of the product, the installation method, and the amount of foot traffic it receives. With proper care and maintenance, engineered wood flooring can last anywhere from 20 to 30 years.

Q5.How do you maintain engineered wood flooring?

A:To maintain engineered wood flooring, it is important to keep it clean and avoid exposing it to excessive moisture. Regular sweeping and vacuuming can help to remove dirt and debris, while spills should be cleaned up immediately. Avoid using harsh cleaning products or abrasive tools that can damage the surface of the flooring.

Q6.Can engineered wood flooring be refinished?

A:In most cases, engineered wood flooring can be refinished, but it depends on the thickness of the top layer of hardwood veneer. Thicker veneers can be sanded down and refinished multiple times, while thinner veneers may not be able to be refinished.

Q7.Is engineered wood flooring a good choice for pets?

A:Yes, engineered wood flooring can be a good choice for homes with pets, as long as the product is designed to withstand high levels of foot traffic and scratches. Some products are also specifically designed to resist stains and moisture, making them a good option for pet owners.

Q8.Is engineered wood flooring environmentally friendly?

A:Engineered wood flooring can be a more environmentally friendly option than solid hardwood, as it uses less hardwood and can be made from sustainable materials. Look for products that are certified by organizations like the Forest Stewardship Council (FSC) to ensure that they are responsibly sourced.

A:Engineerd wood flooring is a type of flooring made up of multiple layers of wood, with a top layer of hardwood veneer. The layers are bonded together with adhesive, making the product more stable and resistant to moisture than solid hardwood flooring.

Q2.How is engineered wood flooring installed?

A: Engineered wood flooring can be installed using different methods, such as floating, glue-down, or nail-down installation. The installation method depends on the specific product and the subfloor.

Q3.What are the benefits of engineered wood flooring?

A:Engineered wood flooring offers several benefits over solid hardwood, including increased stability, resistance to moisture, and a more affordable price point. It can also be installed over concrete subfloors, which is not possible with solid hardwood.

Q4.How long does engineered wood flooring last?

A:The lifespan of engineered wood flooring depends on several factors, such as the quality of the product, the installation method, and the amount of foot traffic it receives. With proper care and maintenance, engineered wood flooring can last anywhere from 20 to 30 years.

Q5.How do you maintain engineered wood flooring?

A:To maintain engineered wood flooring, it is important to keep it clean and avoid exposing it to excessive moisture. Regular sweeping and vacuuming can help to remove dirt and debris, while spills should be cleaned up immediately. Avoid using harsh cleaning products or abrasive tools that can damage the surface of the flooring.

Q6.Can engineered wood flooring be refinished?

A:In most cases, engineered wood flooring can be refinished, but it depends on the thickness of the top layer of hardwood veneer. Thicker veneers can be sanded down and refinished multiple times, while thinner veneers may not be able to be refinished.

Q7.Is engineered wood flooring a good choice for pets?

A:Yes, engineered wood flooring can be a good choice for homes with pets, as long as the product is designed to withstand high levels of foot traffic and scratches. Some products are also specifically designed to resist stains and moisture, making them a good option for pet owners.

Q8.Is engineered wood flooring environmentally friendly?

A:Engineered wood flooring can be a more environmentally friendly option than solid hardwood, as it uses less hardwood and can be made from sustainable materials. Look for products that are certified by organizations like the Forest Stewardship Council (FSC) to ensure that they are responsibly sourced.

Hot Searches