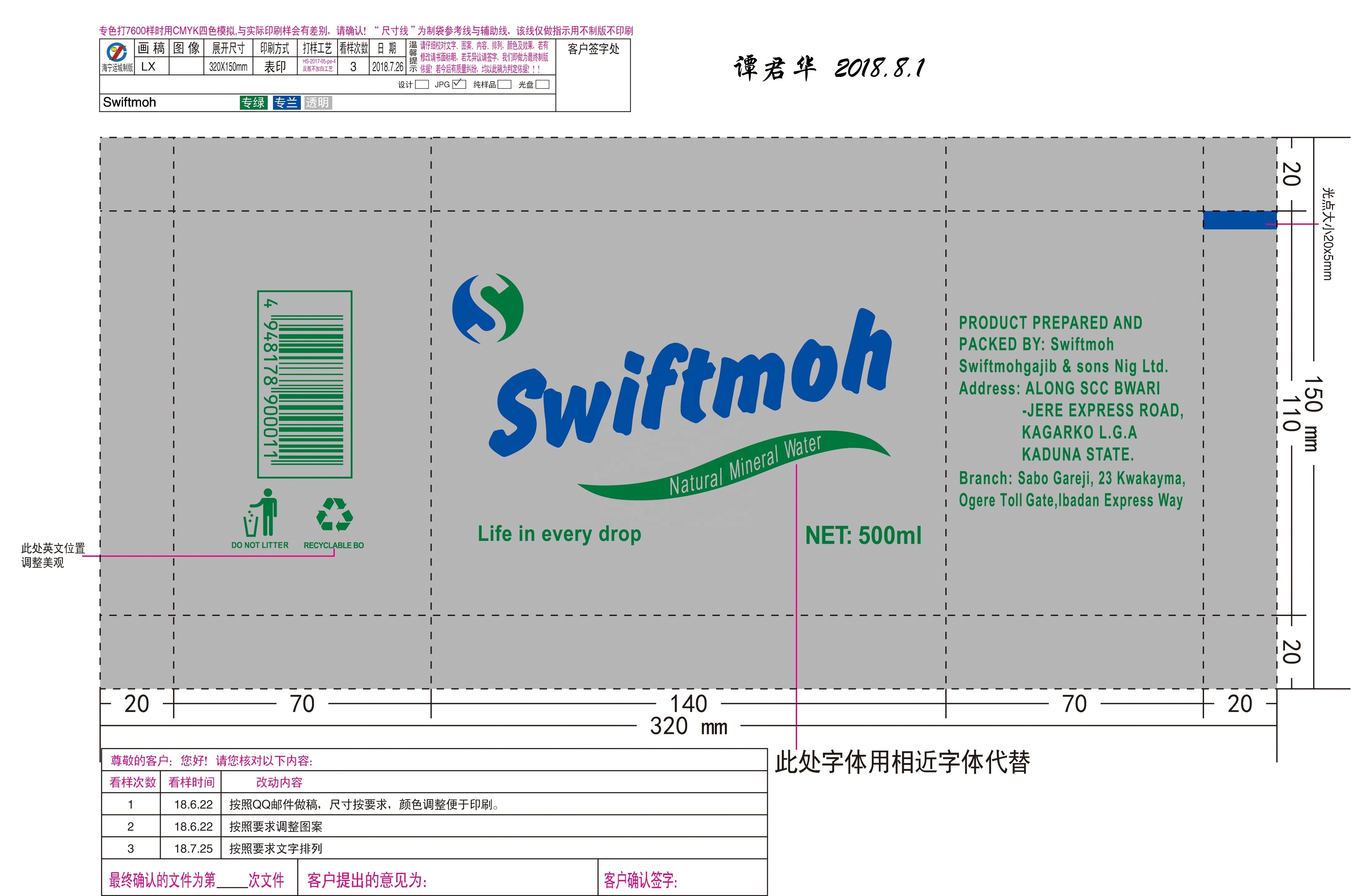

To save shipping freight, we would recommend our customers to find the PE film locally, but we also offer PE film including

printing at a competitive price, and if you are into the most popular sachet / pouch pure/mineral water business, we can also

offer you a total solution including the water treatment, sachet / pouch filling machines, packaging plastic material and even

factory design. Pls consult our sales engineer for more info.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

380V 220V 110V

-

Place of Origin:

-

Shandong

-

Brand Name:

-

LIBAIJIA satchet water filling sealing machine

-

Dimension(L*W*H):

-

1050x850x2050mm

-

Weight:

-

350 KG

-

Packaging film width:

-

150-380mm

-

Packaging capacity:

-

200-1000ML

-

Made bag wide:

-

65-175mm 40-150mm

-

Made bag length:

-

50-250mm

-

Packing speed:

-

1100-1300bags/h 2000-2200bags/H

-

Name:

-

Milk Processing Packaging Machine

-

Function:

-

FILLING Sealing Embossing SLITTING

-

Material:

-

Stainless Steel SS304

-

Marketing Type:

-

Hot Product 2021

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH, Other

-

Packaging Material:

-

Plastic, Other

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder, Other

-

Filling Accuracy:

-

≤0.2%

-

Voltage:

-

380V 220V 110V

-

Place of Origin:

-

Shandong

-

Brand Name:

-

LIBAIJIA satchet water filling sealing machine

-

Dimension(L*W*H):

-

1050x850x2050mm

-

Weight:

-

350 KG

-

Packaging film width:

-

150-380mm

-

Packaging capacity:

-

200-1000ML

-

Made bag wide:

-

65-175mm 40-150mm

-

Made bag length:

-

50-250mm

-

Packing speed:

-

1100-1300bags/h 2000-2200bags/H

-

Name:

-

Milk Processing Packaging Machine

-

Function:

-

FILLING Sealing Embossing SLITTING

-

Material:

-

Stainless Steel SS304

-

Marketing Type:

-

Hot Product 2021

Product Description

Automatic Water Sachet Filling Packaing Machine, Pouch Water Packing Machine

50-500ml Automatic SACHET WATER FILLING MACHINE Water Pouch Packing Machine

Sachet Water Filling and Sealing Machine

small scale water production line sachet/pouch filling machine

Specification

sachet pouch pure mineral water Sachet water Bagged Water Pouch Water filling machines Automatic Liquid Packing Machine Plastic Package BeanMilk Sauce Bag Pure Water Sachet Milk Juice Filling Sealing Machine Operation Gist

1.The pouch filling and sealing machine installs at aeration and dry place, is full of sunshine, makes it stable. This automatic filling machine can fix four feet if neccessary

2.The tube which is going to fill material fills full of water (or 75 Calcohol),the rubber tube cover the material out(avoid

horinzon seal copper cake and then lead to sewer or recycle .The bagging equipment takes 5-10minites to wash pipe while starting the machine.It makes sure to reach the standard of food sanitation.

3.The plastic rool insert to the wheel, and adjust the central line, and make sure the same width when the roll is molding. Then screw the bolt separately. It is good through adjusting the pole of spring stress, ration automatically sway automatically. It is the best for braking well.

4.The sack pass through the tube, then buckle shaped utensil to make sure the strip symmetry. Date adjust to the daily date from up to down yearXX monthXX dayXX.

The vertical hot seal temperature adjusts to 120~150℃,the horizonal seal temperature adjusts to 180~240℃(No more than260℃, or the head of hot seal film is easy to damage),the exact temperature will be adjusted according to the film material and thickness.It can start to fill after pre-heat 20 minites, then it can produce continuously as long as the power is not off.

5.This Sachet Packaging Machine can get the length of sack through adjusting the positon of pole on the winch.Adjusting-in is short, adjusting-out is long. First the power is off, then adjust. First loosen nut then adjust knob. Screw down the nut before starting the machine.

6.The sachet water filling machine can get the filling volumn throught adjusting ration pump on the winch. Adjusting-in is

reduced, adjusting-out is enlarged. The same method with 5.5.

7.The piston is adjustable module. When it used for a peroid, if it is found the piston pole droped, you could loosen the screw on the end piston. Screw piston clockwise, it makes piston large and it will eliminate the phenomonon of drop. ( Note: the adjusting must be small, or the piston is easy to damage). Screw down the screw to prevent loosening after adjusting.

8.The liquid sachet filling machine is ok to press the button and no need workers when it works. The output will show

automatically by the counter. The the film is used up, it need to stop at once, and change into another film, then provide liquid and the machine starts. The PE Bag Water Packing Machine needs to pre-treat and filter when the solid substances is more in the tube which fill the liqui.When the vertical and horizonal seal no viscidity is worn after a peroid, it may loosen the tube to adjust. The bag filling machine can work after screwing down.( it is useless to adjust when it is worn completely). The liquid in the tube can not be more than 0.5meters to insure the precision. The bag filling machines can not be close when starts the machine, and when it has control valve in the liquid pipe.

9.Inspect the vertical and horizonal seal copper cake in a certain time, and clean up the sundries. Or the small bag filling

machine will affect the hot sealing. The bag filling and sealing machine can not be cleaned with metal tool and sand paper, or it will damage the surface and can not work. The bag filling machinery should be cleaned with cloth or wooden organic solvent after the temperature is down, and clean up the sundries.

10.The bag packing machine should rub methylsilicone oil on the vertical and horizonal seal cloth with a certain time, in order to prolong the life of no viscidity cloth and increase the hot sealing.(methylsilicone oil model:210~350CS)。

11.When it appears non-well seal, one sack connects another sack, leakage etc. it forbids pick it up with hands and kinds of tools. The liquid filling machinery should be stoped at once.

12.The automatic bag filling machines is the best condition of all the programme and dimension before delivery. If it needs

experienced technician to maintenance, and write down the dimension, then it can take down.

2.The tube which is going to fill material fills full of water (or 75 Calcohol),the rubber tube cover the material out(avoid

horinzon seal copper cake and then lead to sewer or recycle .The bagging equipment takes 5-10minites to wash pipe while starting the machine.It makes sure to reach the standard of food sanitation.

3.The plastic rool insert to the wheel, and adjust the central line, and make sure the same width when the roll is molding. Then screw the bolt separately. It is good through adjusting the pole of spring stress, ration automatically sway automatically. It is the best for braking well.

4.The sack pass through the tube, then buckle shaped utensil to make sure the strip symmetry. Date adjust to the daily date from up to down yearXX monthXX dayXX.

The vertical hot seal temperature adjusts to 120~150℃,the horizonal seal temperature adjusts to 180~240℃(No more than260℃, or the head of hot seal film is easy to damage),the exact temperature will be adjusted according to the film material and thickness.It can start to fill after pre-heat 20 minites, then it can produce continuously as long as the power is not off.

5.This Sachet Packaging Machine can get the length of sack through adjusting the positon of pole on the winch.Adjusting-in is short, adjusting-out is long. First the power is off, then adjust. First loosen nut then adjust knob. Screw down the nut before starting the machine.

6.The sachet water filling machine can get the filling volumn throught adjusting ration pump on the winch. Adjusting-in is

reduced, adjusting-out is enlarged. The same method with 5.5.

7.The piston is adjustable module. When it used for a peroid, if it is found the piston pole droped, you could loosen the screw on the end piston. Screw piston clockwise, it makes piston large and it will eliminate the phenomonon of drop. ( Note: the adjusting must be small, or the piston is easy to damage). Screw down the screw to prevent loosening after adjusting.

8.The liquid sachet filling machine is ok to press the button and no need workers when it works. The output will show

automatically by the counter. The the film is used up, it need to stop at once, and change into another film, then provide liquid and the machine starts. The PE Bag Water Packing Machine needs to pre-treat and filter when the solid substances is more in the tube which fill the liqui.When the vertical and horizonal seal no viscidity is worn after a peroid, it may loosen the tube to adjust. The bag filling machine can work after screwing down.( it is useless to adjust when it is worn completely). The liquid in the tube can not be more than 0.5meters to insure the precision. The bag filling machines can not be close when starts the machine, and when it has control valve in the liquid pipe.

9.Inspect the vertical and horizonal seal copper cake in a certain time, and clean up the sundries. Or the small bag filling

machine will affect the hot sealing. The bag filling and sealing machine can not be cleaned with metal tool and sand paper, or it will damage the surface and can not work. The bag filling machinery should be cleaned with cloth or wooden organic solvent after the temperature is down, and clean up the sundries.

10.The bag packing machine should rub methylsilicone oil on the vertical and horizonal seal cloth with a certain time, in order to prolong the life of no viscidity cloth and increase the hot sealing.(methylsilicone oil model:210~350CS)。

11.When it appears non-well seal, one sack connects another sack, leakage etc. it forbids pick it up with hands and kinds of tools. The liquid filling machinery should be stoped at once.

12.The automatic bag filling machines is the best condition of all the programme and dimension before delivery. If it needs

experienced technician to maintenance, and write down the dimension, then it can take down.

|

Liquid packing machine

|

|

|

|

|

|

|

||||||

|

Model

|

LBJ-500A

|

LBJ-1000A

|

LBJ-500B

|

LBJ-1000B

|

LBJ-2000B

|

LBJ-500C

|

||||||

|

Production capacity (pouch/h)

|

2000-2200

|

1100-1300

|

1100-1300

|

1100-1300

|

800-1000

|

1100-1300

|

||||||

|

Filling volume(ml)

|

50-500

|

200-1000

|

50-500

|

200-1000

|

500-2000

|

50-250

|

||||||

|

Power (220V/380V)

|

1.6KW

|

2.5KW

|

2.1KW

|

2.5KW

|

2.5KW

|

2.6KW

|

||||||

|

Film width (mm)

|

100-320

|

100-380

|

150-320

|

150-380

|

150-450

|

145-200

|

||||||

|

Weight(kgs)

|

275

|

380

|

370

|

380

|

460

|

275

|

||||||

|

Size(mm)

|

880*760*1800

|

1050*850*2050

|

1050*850*2050

|

1050*850*2050

|

1200*850*2050

|

850*760*1800

|

||||||

Where can I find the source of consumables, say PE film for

Sachet Water Filling Machine

?

Water sachets pure water in Ghana 500-ml plastic pouches

Automatic Drinking Water Liquid Packing Machine

This automatic drinking water Liquid Packing Machine adopts food grade 316/304 stainless steel structure, which reaches the international health standard.This machine has stable and reliable performance, simple operation and low failure rate.

* Widely uses in the milk, the fermented bean curd, each kind of drink, the soy sauce, the vinegar, the liquor and so on each kind of liquid.

* single polyethylene film wrapper, can carry on the ultraviolet ray to be antiseptic automatically, the feed bag formation, the date printing, the quota fill install, seal gather shut off disposable complete.

* The complete machine uses the stainless steel structure, achieves the international sanitation standard.

* Machine performance steady reliable, the operation is simple, the failure rate is low.

* Optional: organic glass shade , Ribbon code printer , ultraviolet radiation sterilization, etc function .

1, we can customize the special size according to customer's demands. 2,The machine disposition may make the choice.

* single polyethylene film wrapper, can carry on the ultraviolet ray to be antiseptic automatically, the feed bag formation, the date printing, the quota fill install, seal gather shut off disposable complete.

* The complete machine uses the stainless steel structure, achieves the international sanitation standard.

* Machine performance steady reliable, the operation is simple, the failure rate is low.

* Optional: organic glass shade , Ribbon code printer , ultraviolet radiation sterilization, etc function .

1, we can customize the special size according to customer's demands. 2,The machine disposition may make the choice.

50-500ml Automatic Sachet Pouch Water Filling and Packing Machine 110V 220V

1. Special sizes can be customized according to customer needs.

2. Fast Delivery/Quality Products/Professional After-sales Services (Video or Picture and Speech tutorials)

3. We are a

manufacturer

of direct sales, 20 years of production and sales of goods experience, the best quality, and service,welcome to consult any relevant machine problems. 4.Shipping channel by sea for 20-30 days! The price is not included Tax and Destination Delivery Charges.

The sachet machine can be used to fill pouches with a wide variety of

liquids such as water, juices, wine, alcoholic beverages,

soy milk, and various other liquids

. This sachet machine has been proven to be very reliable and is very commonly used in areas such as Latin America and Africa, but can be used anywhere worldwide.

The sachet machine fills the sachet with water then uses a heat-sealing system to ensure that the filled sachet or pouch does not leak water. Heat-sealing also ensures that there are no adhesives, glues, or resins used to seal the bag, preventing any possible contamination from sealing. The heat-sealing system uses thermal transverse vertical sealing to seal the bag, meaning that the bag feeds vertically and is thermally (heat) sealed. It is designed to use wither PE film or composite film bags making it versatile to various applications. It can be used with films with preprinted logos or films without logos. The machine then cuts the sachet and drops it into the finished product area.

The water sachet packing machine features date lamination, which laminates the date of production on the bag allowing you to track which pouches were produced on a given date. It also features automatic counting to track the number of bags produced by the machine rather than other machines which do not include this feature.

The sachet machine uses UV sterilization when filling the sachets to prevent any possible contamination. Therefore you can be sure that the water inside the bag has not been contaminated after it has been purified by your water purification system.

The water sachet machine is built to be very reliable and dependable, however, it does come with a 1-year warranty due to

manufacturer defect. It also comes with several free maintenance parts and other parts as well which are listed below.

The ribbon coding machine is a customized part with additional cost.

Liquid pouch filling machine

Liquid bag packaging machine is widely used for packaging various liquid, such as pure water,city water, mineral water,spring water, milk, soybean milk, fruit juice, beverage, ice drink, soy sauce, vinegar and wine, etc. The sachet filling machine makes use of a single layer of PE film as packaging materials. The pouch filling machine automatically sterilized by ultraviolet radiation, it is able to precisely fill, seal and cut at one time. The liquid filling machine is easy to operate and run smoothly with good performance and low failure rate.

1. Bag (sachet )-forming 2. UV sterilization 3. Thermal vertical sealing 4. Date lamination 5. Linear bag traction

6. quantitative filling 7. Thermal transverse sealing

8. Bag-cutting 9. Automatic counting

Water Pouch Packing Machine

Water Pouch Packing Machine Capacity of Production: 1500~2200B/H

Pouch Packing Machine Packing Volume: 100~500ml/B

Filling precision: ±1%

Bag PE Film width: 240mm or 320mm (optional or choose others) Motor power: Singel phrase, Three phrases 1.1KW

Vertical hot seal: 0.3KW; Horizontal hot seal: 0.5KW UV sterilizer lamp: 1.5KW

Power supply: AC220V/Hz or AC380V(three phrases)

The weight of the Sachet Water Packing Machine: 360kg

Normal Type Sachet Filling Machine Dimension(L×W×H): 750*700*1700mm

Pouch Filling Machines With photocell monitoring type Dimension(L×W×H): 750*700*1700mm

Water purification and bagging plants for PURE (SACHET) WATER PRODUCTION Water sachet-packing machine IN NIGERIA Ghana, Complete Water Sachet Produce Line

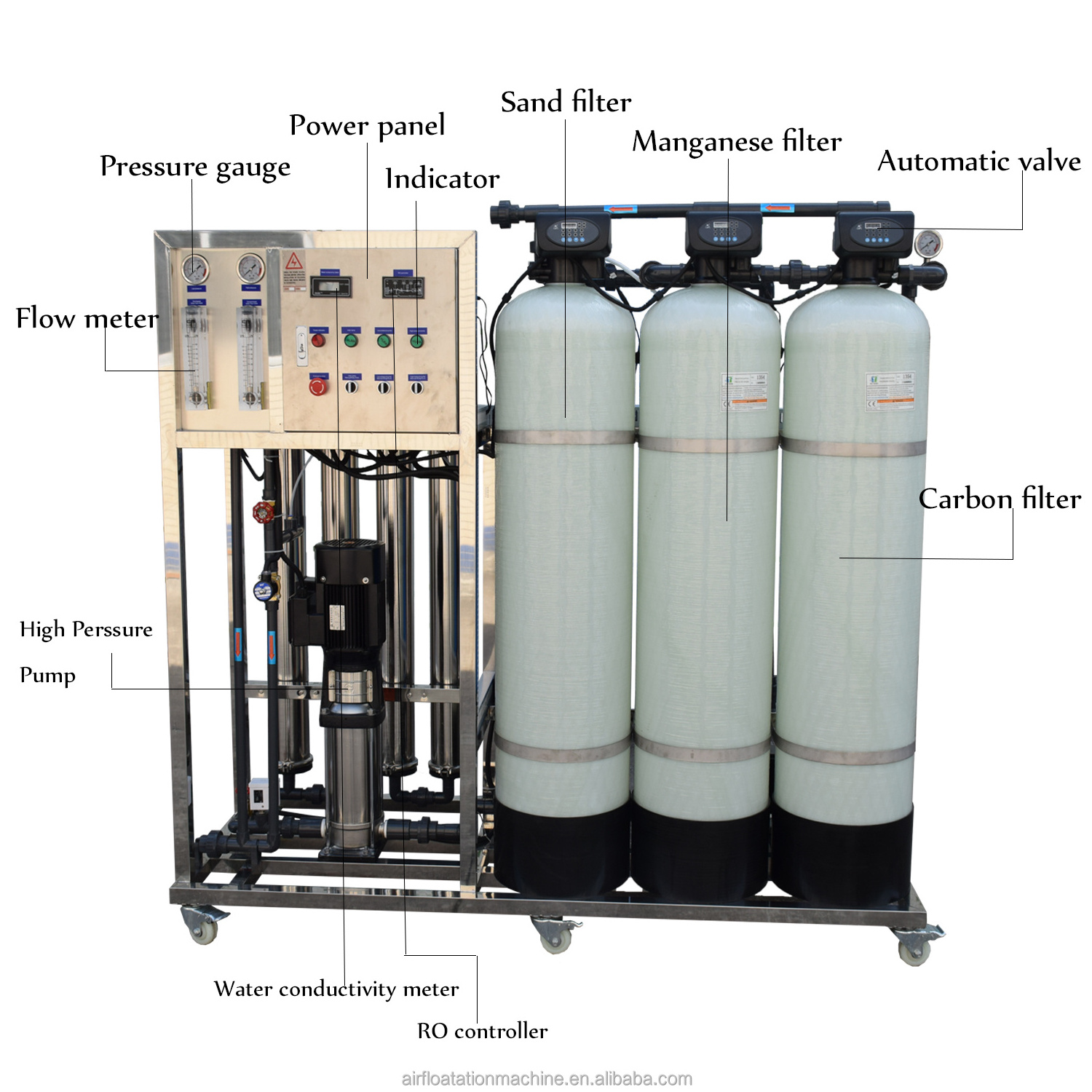

RO water purification system is use to produce pure water and supply pure water for sachet filling machine. It make sure the bag water quality and make sure good drink water. It made your sachet water brand good. Most water sachet water packaging plants are in developing countries with a very large percentage of poor people where the living conditions within the countries are relatively low. Most of the time there is very poor or no infrastructure at all resulting in big problems with electricity and water. The electrical problem can be handled with a generator and in order to get water in most cases you will need a deep well or even have water trucked to site. You can start this business in house. But make sure you need an good RO water purification system to make sure the pouch water quality. Ro system also is widely use in purified bottle water plant. It is the high standard.

Benefits of water bagging, pouches or sachet water Automatic Sachet Water Filling Sealing Machine

Only affordable way to package water in poorer countries.

Can be very profitable; especially in large volume.

Can have printed bags.

The rolls plastic can be shipped at a very low cost vs. bottles

Much better use of plant space as the units are compact.

More environmentally friendly do to less plastic than bottles

Much lower cost to set up plant for bagging vs. bottles.

Street sellers will sell to create jobs.

A small plant running 5 bagger units could produce 80,000 bags per shift. The cost to produce each bag is under $0.01. With a markup of $0.01 you would be able to make 800.00 a shift and many plant will run 16 or 24 hours a day in times of high demand. At this rate the plant could make $2,400 per day in profits when selling at the lowest price possible. If selling at a $.06 profit per bag then the profits would be $4,800.00 per day.

Can be very profitable; especially in large volume.

Can have printed bags.

The rolls plastic can be shipped at a very low cost vs. bottles

Much better use of plant space as the units are compact.

More environmentally friendly do to less plastic than bottles

Much lower cost to set up plant for bagging vs. bottles.

Street sellers will sell to create jobs.

A small plant running 5 bagger units could produce 80,000 bags per shift. The cost to produce each bag is under $0.01. With a markup of $0.01 you would be able to make 800.00 a shift and many plant will run 16 or 24 hours a day in times of high demand. At this rate the plant could make $2,400 per day in profits when selling at the lowest price possible. If selling at a $.06 profit per bag then the profits would be $4,800.00 per day.

How Can We Help? Pure Water Factory Set-up, Maintenance of sachet water machine, SETUP THE WATER SACHET WATER POUCH FACTORY IN AFRICA

We specializes manufacturer water purification equipment such as water filtration systems to produce pure water for your sachet plant. We also offer sachet filling machine and water bagging machine that are currently used worldwide. We will assist you with establishing your bagged water purification and packaging plant from the conception of the idea to when you are ready to open your plant. Please call or email us to find out more on this profitable business and to see how LIBAIJIA (Shandong) Water Treatment Equipment Co.,Ltd can help you start your operation.

Life-long maintance consulting service by Email, and Telephone. If necessary, we send our engineer to amend it abroad for you.However, the cost for our engineer such as dormitory,travel cost is on buyer’s account.

Warranty: One year factory maintance guarantee and life-long service by Email, and Telephone information.

Warranty: One year factory maintance guarantee and life-long service by Email, and Telephone information.

1. Drilling of boreholes

2. Supply & Installation of Water Packaging Machine

3. Supply & Installation of Water Treatment Machine

4. Engineering the Sachet water Production Line unit

2. Supply & Installation of Water Packaging Machine

3. Supply & Installation of Water Treatment Machine

4. Engineering the Sachet water Production Line unit

How to setup the water sachet water pouch factory in Africa? The best is setup the complete line,it include the pure water treatment with RO system,pure water tank,sachet water filling machine, UV sterilizer and so on.

For the sachet water producing line,the smallest produce capacity is 2000sachet/h,If need the bigger type,it can make ad your request.

FAQ

Automatic Sachet Water Bag Packing Machine

300ml 500ml 600ml Plastic Pouch Mineral Water Bag Filling Sealing Packing Machine

pouch water filling machine water bag packing machine

Q1: Are you manufacturer or trade company?

A1:We are a professional manufacturer for producing machinery over 10 years.

Q2: How is the quality of your product?

A2: Our products are manufactured according to national and international standard, and we have a test on every machine before delivery.

Q3: How about the price?

A3: We are a professional manufacturer and be able to provide you with the lowest price than market one. We will give you the best quotation.

Q4:What if the machine is damaged?

A5:One year warranty and all-round after-sales service. After this deadline, we shall charge at low cost to keep after-sales

service.

A1:We are a professional manufacturer for producing machinery over 10 years.

Q2: How is the quality of your product?

A2: Our products are manufactured according to national and international standard, and we have a test on every machine before delivery.

Q3: How about the price?

A3: We are a professional manufacturer and be able to provide you with the lowest price than market one. We will give you the best quotation.

Q4:What if the machine is damaged?

A5:One year warranty and all-round after-sales service. After this deadline, we shall charge at low cost to keep after-sales

service.

Hot Searches