- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

E-Work

-

Voltage:

-

50Hz, 220V, 50Hz, 220V

-

Dimension(L*W*H):

-

700*700*735mm

-

Weight (KG):

-

170

-

Product name:

-

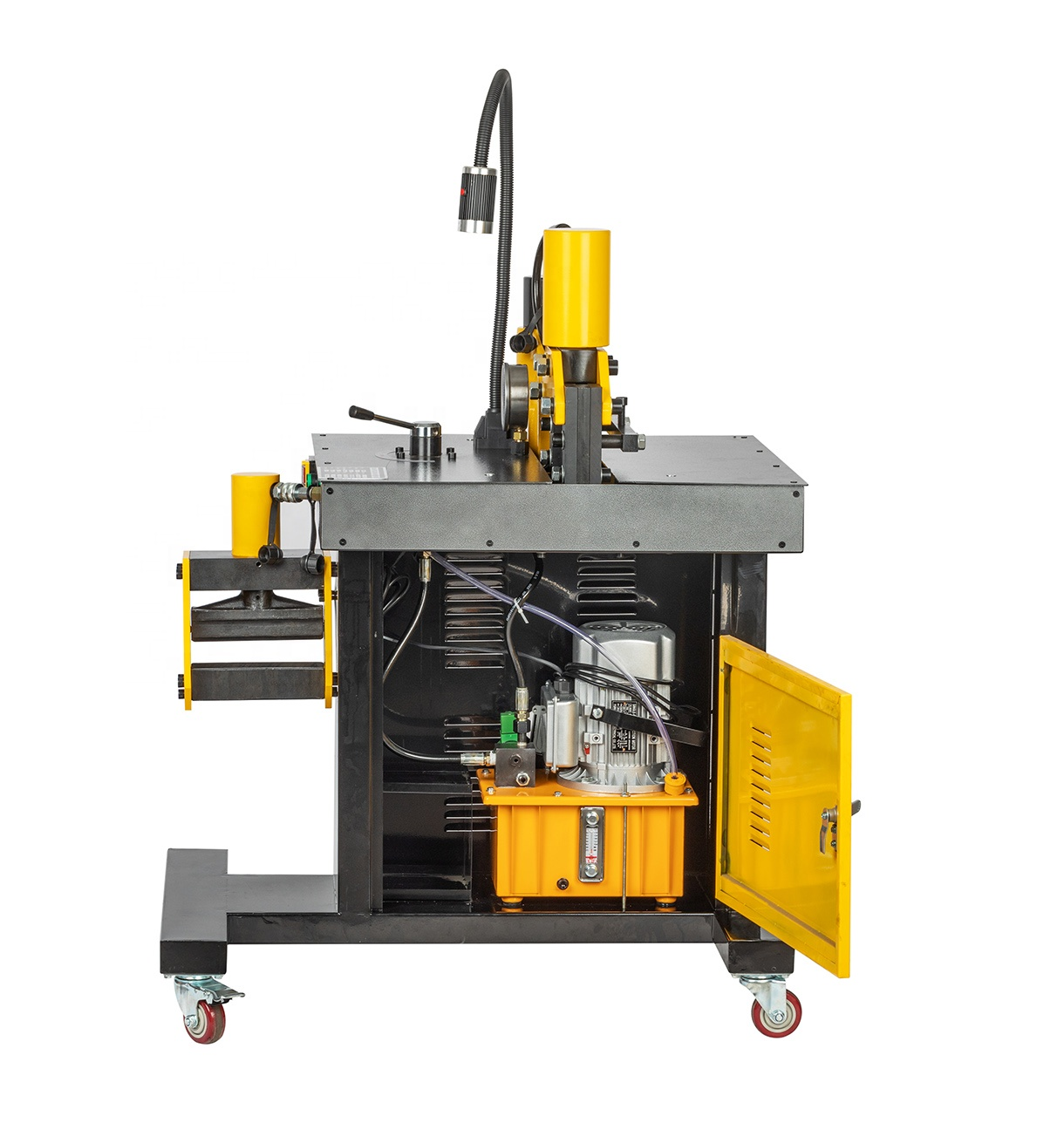

Multi-functional busbar processing machine

-

Application:

-

Cutting Bending Punching

-

Processing material:

-

Copper/Aluminium busbar

-

Processing mode:

-

Cold processing

-

Model:

-

VHB-150

-

Output cutting force:

-

15t

-

Output punching force:

-

31t

-

Output bending force:

-

16t

-

Color:

-

Yellow

Quick Details

-

Max. Thickness (mm):

-

10 mm

-

Max. Width (mm):

-

150 mm

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

E-Work

-

Voltage:

-

50Hz, 220V, 50Hz, 220V

-

Dimension(L*W*H):

-

700*700*735mm

-

Weight (KG):

-

170

-

Product name:

-

Multi-functional busbar processing machine

-

Application:

-

Cutting Bending Punching

-

Processing material:

-

Copper/Aluminium busbar

-

Processing mode:

-

Cold processing

-

Model:

-

VHB-150

-

Output cutting force:

-

15t

-

Output punching force:

-

31t

-

Output bending force:

-

16t

-

Color:

-

Yellow

Product Description

Multi-functional busbar processing machine

This processor is suitable for making large electric cabinets, power distribution cabinets, switch cabinets, and power transmission and distribution construction engineering construction site use. Suitable for transmission and distribution in a large workshop and site work, construction, and power distribution cabinets and switch cabinets, etc.

This machine is equipped with the functions of bending, cutting, and punching .

1. Punching machine

CH-70 and CH-60 split hydraulic punching machines are specially used for angle iron flat iron. Punching holes for metal plates such as copper plates is especially suitable for field operation for electric power; construction and other industries. Manual and pedal electric pumps can be selected at will.

2. Bending, cutting machine

It is suitable for wiring projects such as a switch box, switchboard,s and automatic control panels. It is easy to carry by separating type and can be equipped with a manual pedal electric pump. CWC series cut copper bar products are not concave and convex, and they are very characteristic products.

The bending angle of the bent copper bar or aluminum bar is correct at 90 degrees, and the material of the copper bar is not damaged.

CB-150D is liftable. When bending a long copper bar, an N-shaped L-shaped can remove the latch, so the whole bar can be taken out without hindrance.

The design is provided with 90-degree and 45-degree angle indications, which can be equipped with CP-700, CFP-800, DBD750 series pumps, etc.

3. Horizontal and vertical bending machine

Horizontal and vertical bending machine is suitable for bus bending in line construction. This machine takes the hydraulic pump as the power pump and can complete the flat and vertical bending of copper-aluminum bus bars by using different dies. Compared with similar products, this machine has the advantages of volume, beautiful appearance, lightweight and easy carrying, and is a right-hand man for linemen.

This machine is equipped with the functions of bending, cutting, and punching .

1. Punching machine

CH-70 and CH-60 split hydraulic punching machines are specially used for angle iron flat iron. Punching holes for metal plates such as copper plates is especially suitable for field operation for electric power; construction and other industries. Manual and pedal electric pumps can be selected at will.

2. Bending, cutting machine

It is suitable for wiring projects such as a switch box, switchboard,s and automatic control panels. It is easy to carry by separating type and can be equipped with a manual pedal electric pump. CWC series cut copper bar products are not concave and convex, and they are very characteristic products.

The bending angle of the bent copper bar or aluminum bar is correct at 90 degrees, and the material of the copper bar is not damaged.

CB-150D is liftable. When bending a long copper bar, an N-shaped L-shaped can remove the latch, so the whole bar can be taken out without hindrance.

The design is provided with 90-degree and 45-degree angle indications, which can be equipped with CP-700, CFP-800, DBD750 series pumps, etc.

3. Horizontal and vertical bending machine

Horizontal and vertical bending machine is suitable for bus bending in line construction. This machine takes the hydraulic pump as the power pump and can complete the flat and vertical bending of copper-aluminum bus bars by using different dies. Compared with similar products, this machine has the advantages of volume, beautiful appearance, lightweight and easy carrying, and is a right-hand man for linemen.

Product features

1. The overall shape is bright in color, and the surface is abrasion-resistant and impact-resistant through anti-rust treatments such as baking paint and phosphoric acid peeling.

2. The beautiful and generous workbench is polished and chrome-plated to present a precise and stable working surface.

3. The plate seat can be directly debugged, the long and short-dimension standards can be freely selected, and the control specifications are unified.

4. The four-way valve control switch has simple operation, accurate instruction, and accurate use, which makes the punching tool, bending tool, and cutting tool safe and reliable in the working process.

2. The beautiful and generous workbench is polished and chrome-plated to present a precise and stable working surface.

3. The plate seat can be directly debugged, the long and short-dimension standards can be freely selected, and the control specifications are unified.

4. The four-way valve control switch has simple operation, accurate instruction, and accurate use, which makes the punching tool, bending tool, and cutting tool safe and reliable in the working process.

Specification

|

Model

|

|

VHB-150

|

|

||

|

Name

|

|

Multi-functional busbar processing machine

|

|

||

|

Function

|

|

Cutting machine(CWC-150)

|

|

||

|

|

|

Bending machine(CB-150D)

|

|

||

|

|

|

Punching machine(CH-60)

|

|

||

|

Dimension of Mobile workbench

|

|

700(L)*700(W)*735(H)mm

|

|

||

|

Control voltage

|

|

Single-phase 50Hz, 220V

|

|

||

|

Rated fuel pressure

|

|

700kg/cm²

|

|

||

|

Cutting

|

Cutting Output

|

15T

|

|

||

|

|

Cutting capacity

|

150mm*10mm (Copper/Aluminium busbar)

|

|

||

|

Punching

|

Punching Output

|

31T

|

|

||

|

|

Depth of throat

|

95mm

|

|

||

|

|

Punching capacity

|

iron plate

|

6mm

|

||

|

|

|

Copper/Aluminium busbar

|

10mm

|

||

|

|

|

Processing Copper/Aluminium busbar

|

150mm*10mm

|

||

|

|

|

Standard matching punching mold (mm)

|

Φ7 Φ9 Φ10.5 Φ13.8 Φ17.5 Φ20.5

|

||

|

Bending

|

Bending Output

|

16T (Horizontal bending)

|

|

||

|

|

Bending capacity

|

150mm*10mm (Copper/Aluminium busbar)

|

|

||

|

Weight

|

|

170kg

|

|

||

Product advantages

1. This machine provides efficiency and guarantee safety requirement and the design of form a complete set of equipment.

2. The machine is equipped with bending, cutting, and punching functionality.

3. Punch holes without burr, cutting surface smooth, and cutting angle accurately. it is good for pick and repeat batch procession.

4. High flexibility, small volume, big power, high production capacity, and high work efficiency.

5. Safe and firm pedal switch could control the oil inlet and oil return. Low noise, harmless processing.

6. Finishing product is beautiful and won't cause pollution to the environment.

2. The machine is equipped with bending, cutting, and punching functionality.

3. Punch holes without burr, cutting surface smooth, and cutting angle accurately. it is good for pick and repeat batch procession.

4. High flexibility, small volume, big power, high production capacity, and high work efficiency.

5. Safe and firm pedal switch could control the oil inlet and oil return. Low noise, harmless processing.

6. Finishing product is beautiful and won't cause pollution to the environment.

Product structure

Detailed Images

Detailed photos of

Multi-functional bus bar processing machine

Detailed photos of the

package

for the Multi-functional bus bar processing machine

Detailed photos about

on-site application

for Multi-functional bus bar processing machine

Hot Searches