- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer's Demand

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1300*1300*3200mm

-

Weight:

-

1360

-

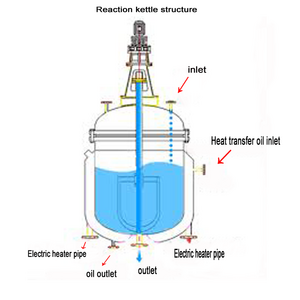

Machine Type:

-

Reactor kettle

-

Motor:

-

5.5kw

-

Application:

-

PVA glue

-

Function:

-

Automatic Production Line

-

Material:

-

Stainless Steel 316L

-

Mixing shaft:

-

Anchor and paddle mixing type

-

Heating method:

-

Electric Heating

-

Sealing Type:

-

Machanical Seal

-

Discharge:

-

Bottom ball valve discharge

Quick Details

-

Capacity:

-

1000L, 1000L

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Voltage:

-

Customer's Demand

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

1300*1300*3200mm

-

Weight:

-

1360

-

Machine Type:

-

Reactor kettle

-

Motor:

-

5.5kw

-

Application:

-

PVA glue

-

Function:

-

Automatic Production Line

-

Material:

-

Stainless Steel 316L

-

Mixing shaft:

-

Anchor and paddle mixing type

-

Heating method:

-

Electric Heating

-

Sealing Type:

-

Machanical Seal

-

Discharge:

-

Bottom ball valve discharge

1000L Chemical Industrial Stainless Steel Reactor Kettle for Glue

Introduction:

1. Suitable for large scale production

2. It could provide special configuration according to different technique output requests

3. Design yearly output: 3000-100000MT

4. Automatic production and vaccum material absorption is adopted

5. Automatic matage, online checking, and the entire valve adopt electric comtrol valve, automatically controlled by cpmputer

6. High investment and high output

7. It continuously completes the whole technical process of vacuum, dispersing, milling, paint mixing, filtering, fillig, etc. One working procedure from material feeding to finshed products.

8. Imported double-layer mighty dispersing plate is adopted, which has high dispersing efficiency.

9. Each paint mixing tank discharges separately; pipeline is easy to clean; combined production is convenient.

Application:

Liquid paint, acrylic wall paint, powder coating, water-based paint, oil-based paint, interior &. exterior decorative paint, emulsion paint, latex paint, etc.