Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

138 mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

250 cm³

-

Injection Rate (g/s):

-

120 g/s

-

Injection Weight (g):

-

231 g

-

Screw Speed (rpm):

-

150 - 180 rpm

-

Screw diameter (mm):

-

43 mm

-

Screw L/D Ratio:

-

22.4

-

Distance between Tie Bars:

-

430*390 mm

-

Weight (KG):

-

4200 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

380 mm

-

Model Number:

-

MW1500

-

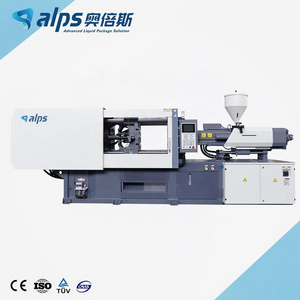

Brand Name:

-

MAIWEI

-

Power (kW):

-

37 kW

-

Product name:

-

Preform making machine

-

Keyword:

-

PP PE PET Injection Molding Machine

-

Function:

-

Plstic Injection Molding Machinery

-

Application:

-

Inserting Plastic Products

-

Used for:

-

Plasic Products

-

Injection Pressure(Mpa):

-

152-185

-

Clamping Force(KN):

-

1500

-

Pump Pressure(Mpa):

-

15

-

Color:

-

Customrized

-

After-sales Service:

-

Over-sea Service Provided

Quick Details

-

Style:

-

N/A

-

Plasticizing Capacity(g/s):

-

19

-

Mold Height(mm):

-

150 - 430 mm

-

Ejector Stroke(mm):

-

138 mm

-

Ejector Force(kN):

-

45 kN

-

Theoretical Shot Volume(cm³):

-

250 cm³

-

Injection Rate (g/s):

-

120 g/s

-

Injection Weight (g):

-

231 g

-

Screw Speed (rpm):

-

150 - 180 rpm

-

Screw diameter (mm):

-

43 mm

-

Screw L/D Ratio:

-

22.4

-

Distance between Tie Bars:

-

430*390 mm

-

Weight (KG):

-

4200 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

380 mm

-

Model Number:

-

MW1500

-

Brand Name:

-

MAIWEI

-

Power (kW):

-

37 kW

-

Product name:

-

Preform making machine

-

Keyword:

-

PP PE PET Injection Molding Machine

-

Function:

-

Plstic Injection Molding Machinery

-

Application:

-

Inserting Plastic Products

-

Used for:

-

Plasic Products

-

Injection Pressure(Mpa):

-

152-185

-

Clamping Force(KN):

-

1500

-

Pump Pressure(Mpa):

-

15

-

Color:

-

Customrized

-

After-sales Service:

-

Over-sea Service Provided

Product details

Products Description

Bottle Preform Machine

There is a large variety of preform machines available at our store. The wide-neck preform machine, hot filling bottle, and 20-liter bottle preform machine are available in diverse sizes and designs. We always follow stringent control measures to provide high-quality preform machines considering your industrial budget.

Feature of Injection Machine

1).Power saving: Save power 30%-60%

2).Oil saving: Using high performance filter device to increase using life of hydraulic oil.

3).High speed: Increase 20% performance capacity by using variable displacement pump.

4).No overflowing heating, low oil temperature saves cooling water, and increases the using life of sealing elements.

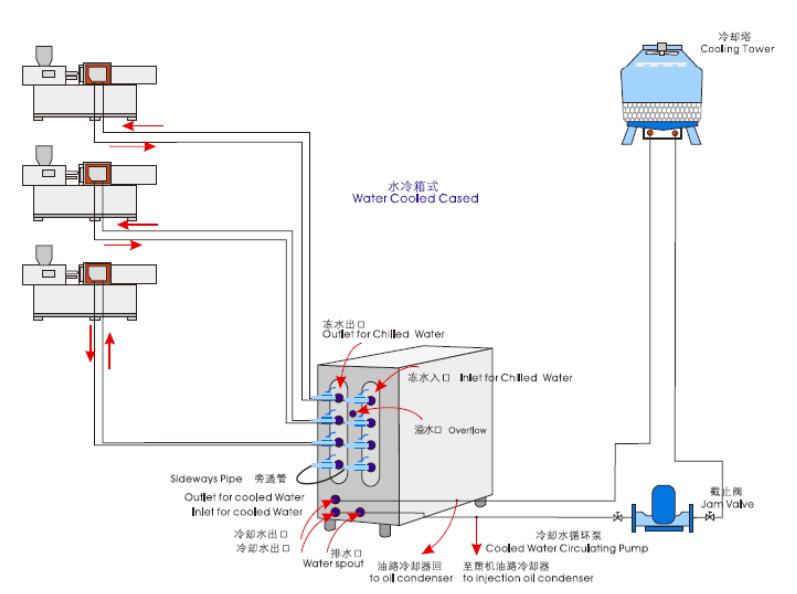

Illustration for installing xinre industrial chiller

plastic dryer

·

Well -distributed Heated Wind: The heat efficiency is high enough to shorten great amount of drying time

·

Precise Temperature Controls: The precise temperature controls ensure and keep a high accuracy of temperature

·

Save Time and Manpower: As the hopper body and bottom are designed separately, and therefore it is very convenient

strong crusher

·

Imported special tool steel exquisite knives, the clearance of the knives can be adjusted, and the sharpening can be removed repeatedly after being blunt, durable

·

High-strength steel screws are used to fasten the blade and the knife seat, with strong bearing capacity

·

The surrounding wall of the crushing chamber is sound-insulated, the noise is extremely small, and the heavy-duty bearing and dust-proof device

Machine Paramenters

|

Model

|

Unit

|

MW1500

|

|

|

||||

|

Injection Unit

|

|

A

|

B

|

C

|

||||

|

Screw Diameter

|

mm

|

39

|

41

|

43

|

||||

|

Screw L/D Ratio

|

L/D

|

22.4

|

21

|

20

|

||||

|

Theoretical Shot Voleme

|

cm³

|

160

|

200

|

250

|

||||

|

Actual Shot Quality(ps)

|

g

|

147

|

185

|

231

|

||||

|

Actual Shot Quality(ps)

|

oz

|

5.2

|

6.5

|

8.1

|

||||

|

Injection Rate(ps)

|

g/s

|

98

|

106

|

120

|

||||

|

Plasticing Capacity(ps)

|

g/s

|

13.7

|

16.1

|

17.8

|

||||

|

Injection Pressure

|

Mpa

|

185

|

168

|

152

|

||||

|

Screw Speed

|

rpm

|

180

|

180

|

180

|

||||

|

Clamping Unit

|

|

|

|

|

||||

|

Clamping Force

|

KN

|

1500

|

|

|

||||

|

Platen Stroke

|

mm

|

380

|

320

|

|

||||

|

Distance Between

|

mm

|

430X390

|

|

|

||||

|

Max.mould Thickness

|

mm

|

410

|

|

|

||||

|

Min.mould Thickness

|

mm

|

130

|

|

|

||||

|

Ejector Stroke

|

mm

|

138

|

|

|

||||

|

Ejector Force

|

KN

|

42

|

|

|

||||

|

No.of Ejector

|

PC

|

5

|

|

|

||||

|

Others

|

|

|

|

|

||||

|

Max.pump Pressure

|

Mpa

|

15

|

|

|

||||

|

Hopper Heating Power

|

KW

|

7.55

|

|

|

||||

|

Pump Motoa Power

|

KW

|

15

|

|

|

||||

|

Dimension(LxWxH)

|

m

|

4.56x1.33x1.91

|

|

|

||||

|

Weight

|

t

|

4.2

|

|

|

||||

Hot Searches