Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

38.5 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GEGAO

-

Voltage:

-

380V 50HZ 3P, 380V 50HZ; 220V 60HZ

-

Weight:

-

1200 KG

-

Pipe Material:

-

OPVC

-

Diameter:

-

90-630MM

-

Screw design:

-

double-screw

-

Type:

-

plastic opvc pipe

-

Processing Type:

-

Pipe Extrusion Machine

-

Keywords:

-

opvc pipe machine

-

Raw material:

-

pvc powder

-

Function:

-

Pipe Making

Quick Details

-

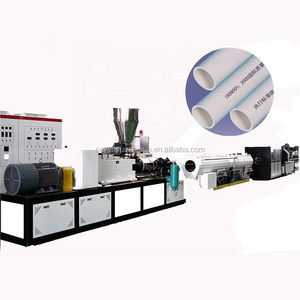

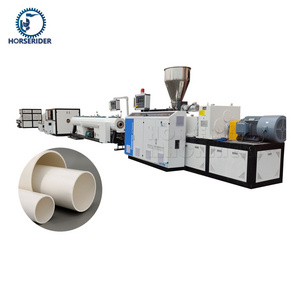

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

78

-

Screw Speed (rpm):

-

38.5 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GEGAO

-

Voltage:

-

380V 50HZ 3P, 380V 50HZ; 220V 60HZ

-

Weight:

-

1200 KG

-

Pipe Material:

-

OPVC

-

Diameter:

-

90-630MM

-

Screw design:

-

double-screw

-

Type:

-

plastic opvc pipe

-

Processing Type:

-

Pipe Extrusion Machine

-

Keywords:

-

opvc pipe machine

-

Raw material:

-

pvc powder

-

Function:

-

Pipe Making

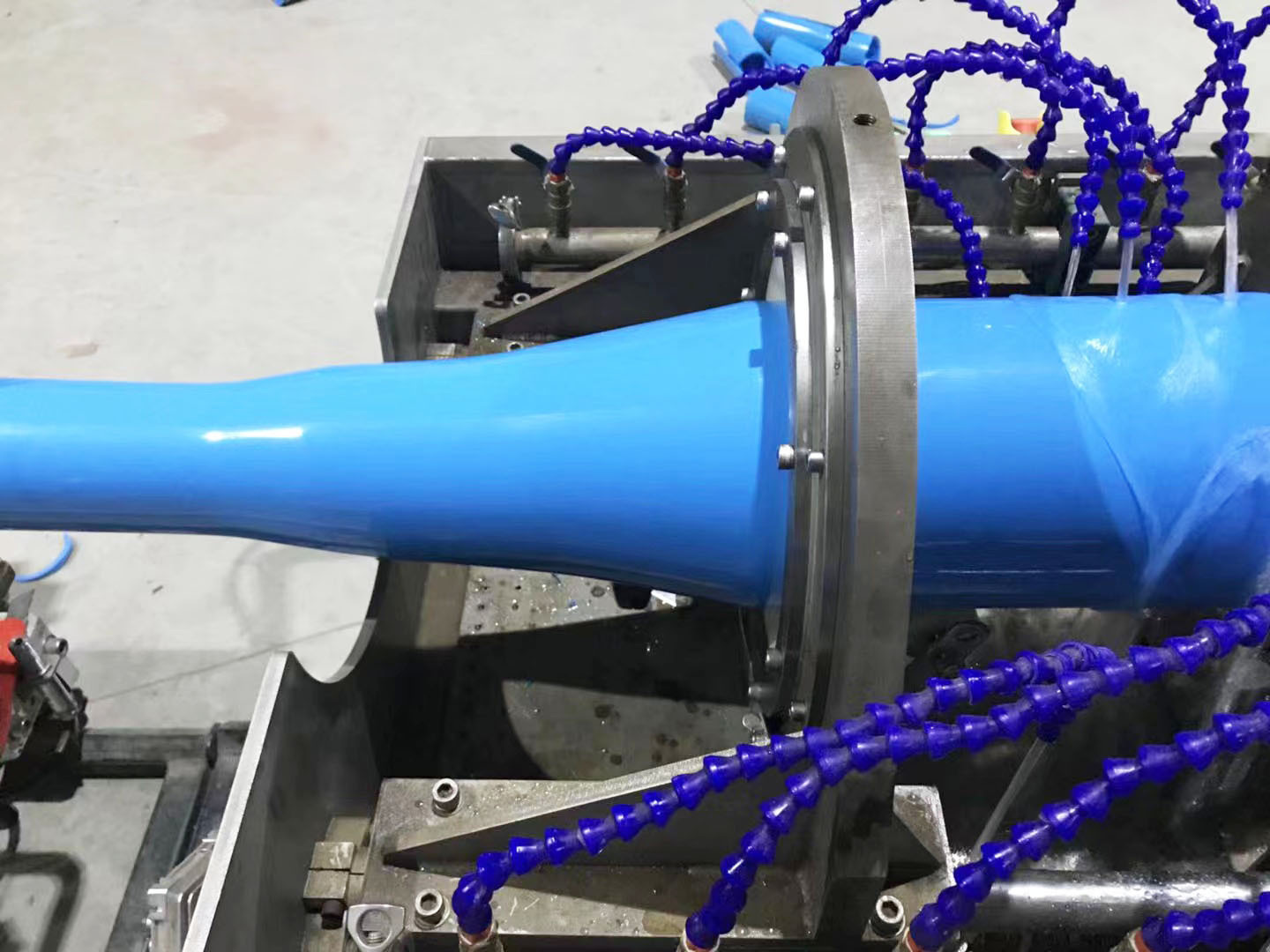

Oriented polyvinyl chloride pipes are a sort of new generation pipes which can be used for water conveyance at high pressure. OPVC pipes are generally of higher standard and quality as compared to other piping systems.

|

Pipe material

|

PVC powder

|

|

Pipe diameter

|

90-630mm

|

|

Pipe machine

|

Mixing→Extruder→Mold→Vacuum tank→Haul-off→Oven→Forming→Haul-off→Cutting→Belling machine

|

Product Description

The production method of the tube blank part of PVC-O pipe is basically the same as that of PVC-U. The basic process is as follows:

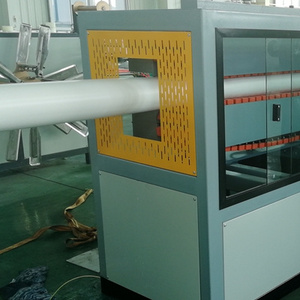

Raw materials → Mixing → Extruder plasticization → Mold forming → Vacuum cooling and shaping → Traction → (preheating + orientation)

Enterprises with PVC-U production lines can use existing equipment to transform and produce PVC-O pipes.

The raw materials used in PVC-O are exactly the same as those used in PVC-U, and both use resin with a K value ≥ 64.

We have tested most brands of PVC resin on the market, and basically all resins can meet the production process requirements of PVC-O pipes.

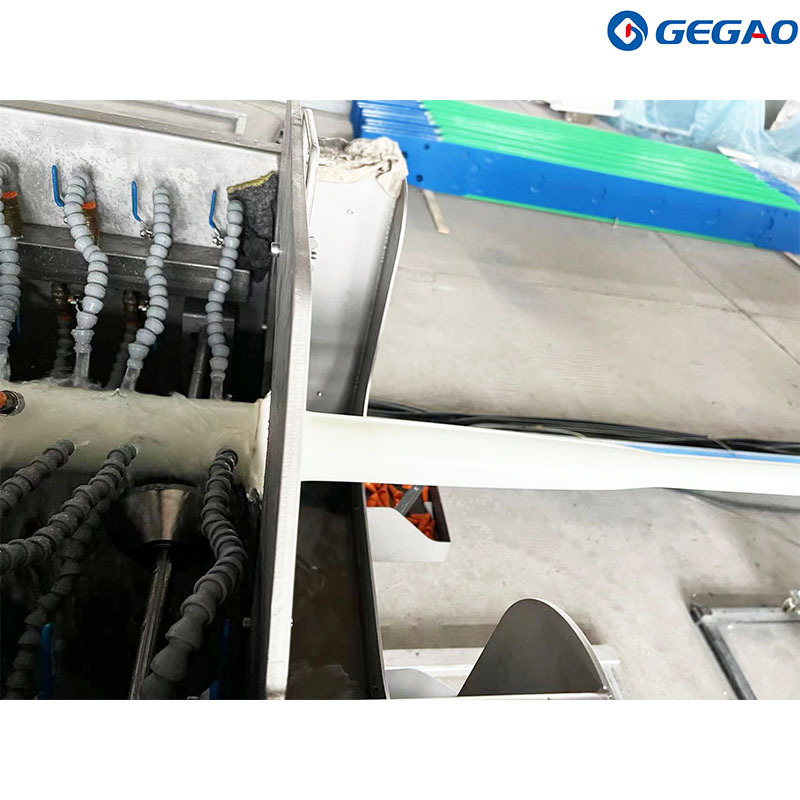

The pipe extrusion mold is a very core part. The mold must be able to meet the uniform extrusion of materials. There must be no material merging lines on the inner and outer walls of the tube blank. It also needs to be equipped with complex cooling and pneumatic pipelines. In addition, the mold must also bear the traction machine shaft. Because the bidirectional stretching expansion mold is directly connected to the pipe mold through a connecting rod, all the axial pulling force acts on the bracket of the mold.

1. Most polymers can have their molecules arranged regularly through orientation processes, which can significantly improve their physical properties. Some of our common polymer products achieve excellent performance through oriented manufacturing processes, such as various fibers, blow molded containers, blown film products, etc. The orientation process can greatly improve the comprehensive performance of polymer pipes and reduce the consumption of raw materials. It will be an important development direction of pipes in the future. PVC-O biaxially oriented polyvinyl chloride pipes are pipes produced using this manufacturing process. This process is to bidirectionally stretch the extruded PVC-U pipes in the axial and radial directions to make the long PVC molecules in the pipes The chains are arranged in an orderly manner in the biaxial direction, thereby greatly improving the strength, toughness, impact resistance, fatigue resistance, low temperature resistance and other properties of PVC pipes. The performance of the new pipes obtained by this process greatly exceeds that of ordinary PVC-U pipes. 2. Research shows that compared with PVC-U pipes, PVC-O pipes can significantly save raw material resources, reduce costs, improve the overall performance of pipes, and have lower construction and installation costs.

Final product

Packing&Shipping

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client’s warehouse to loading

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client’s warehouse to loading

Our Services

Company Introduction

Our company occupies an area of 20,000 square meters, and we own 7,000-square-meter international standard factory building.

Our company is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, cone double -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

Our company is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, cone double -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

Certifications

FAQ

Q:Are you machinery factory or trading company?

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days.

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days.

Recommend Products

Hot Searches