- Product Details

- {{item.text}}

Quick Details

-

Length:

-

According to customer requirements, From 10mm to 10000mm for self reverse ball screw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Matech

-

Item Name:

-

Directly Sale Air Pressure Miniature Self Reverse Ball Screw

-

Grade:

-

C7, C5, C3 for self reverse ball screw

-

Application:

-

CNC machine, 3D printing machinery, chemical machinery and so on

-

Nut type:

-

Single or double nuts

-

Production Process:

-

Cold Rolling, CNC Grinding, Whirling Milling

-

Package for ball screw:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

3 days for sample order, bulk order need to be negotiated

-

Service:

-

Custom self reverse ball screw based on drawings or samples

Quick Details

-

Weight (KG):

-

1

-

Marketing Type:

-

customized products

-

Material:

-

steel,or customized, Bearing steel, alloy steel, GCr15 and so on

-

Length:

-

According to customer requirements, From 10mm to 10000mm for self reverse ball screw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Matech

-

Item Name:

-

Directly Sale Air Pressure Miniature Self Reverse Ball Screw

-

Grade:

-

C7, C5, C3 for self reverse ball screw

-

Application:

-

CNC machine, 3D printing machinery, chemical machinery and so on

-

Nut type:

-

Single or double nuts

-

Production Process:

-

Cold Rolling, CNC Grinding, Whirling Milling

-

Package for ball screw:

-

Multilayer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

3 days for sample order, bulk order need to be negotiated

-

Service:

-

Custom self reverse ball screw based on drawings or samples

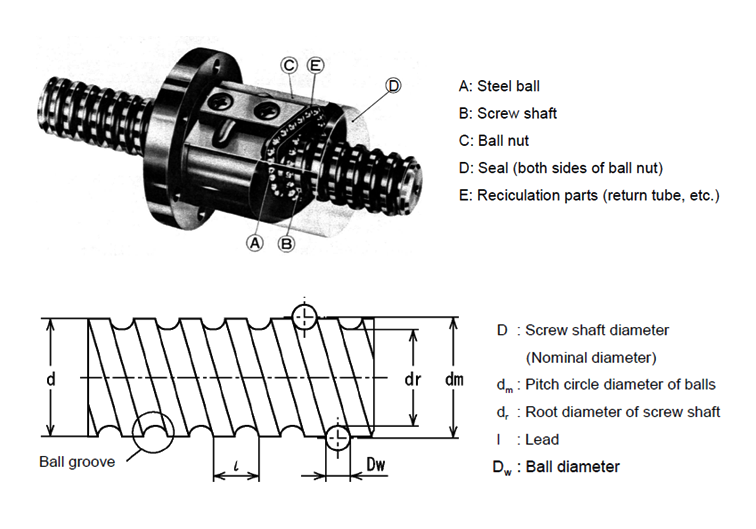

Products Description

|

Item Name

|

Custom Factory Directly Sale Air Pressure Miniature Self Reverse Ball Screw

|

|

Material

|

Bearing steel, alloy steel, GCr15 and so on

|

|

Grade

|

C7, C5, C3 for miniature ball screw

|

|

Length

|

From 10mm to 10000mm for miniature ball screw, can be customized based on customers requirement

|

|

Flange Type

|

No cutting, Single Cutting, Double Cutting

|

|

Nut type

|

Single or double nuts

|

|

Produce Code

|

Ground, Rolled for miniature ball screw

|

|

Production Process

|

Cold Rolling, CNC Grinding, Whirling Milling

|

|

Feature

|

High stiffness

High efficiency High load & speed High Precision & low noise |

|

Application

|

CNC machine, 3D printing machinery, chemical machinery, woodworking machinery, engraving machines, window machines, high speed machinery, semi-conductor equipment, robot, railways, automation applicationand etc

|

|

Our Services

|

Custom miniature ball screw based on drawings or samples

|

|

Delivery Time

|

3 days for sample order, bulk order need to be negotiated

|

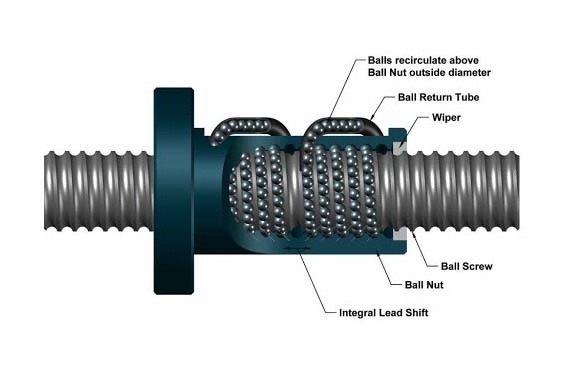

Ball screw according to GB classification there are P class and T class, that is, transmission class and positioning class, the accuracy level has 1, 2, 3, 4 ..... Several kinds, foreign products generally do not distinguish transmission or positioning, all to C0 ~ C10 or specific values.

In general, general-purpose machinery or ordinary CNC machinery selected C7 (any 300 stroke within the positioning error ± 0.05) or below, high-precision CNC machinery selected C5 (± 0.018) above C3 (± 0.008) below, optical or detection machinery selected C3 above.

Ball screw bearing specifications selection

(1) Determine the positioning accuracy;

(2) Determine the lead of the ball screw bearing by the motor and the speed requirement;

(3) Check the nut size to determine the stroke and related data of the shaft end of the screw bearing;

(4) Determine the average axial force and speed by load and speed distribution (acceleration and deceleration);

(5) Determine the pre-pressure from the average axial force;

(6) Determine the dynamic load rating by life expectancy, axial load and speed;

(7) Determine the outer diameter of the screw bearing and the nut form by the basic dynamic load rating, lead, critical speed, and DmN value limit;

(8) The outer diameter, nut, preload, and load determine the rigidity (machine design);

(9) Ambient temperature, total length of the nut to determine the thermal variation and cumulative lead;

(10)Screw bearing rigidity, thermal variation position to determine the pre-tension;

(11)Maximum machine speed, temperature rise time, and screw bearing specifications determine motor drive torque and specifications.

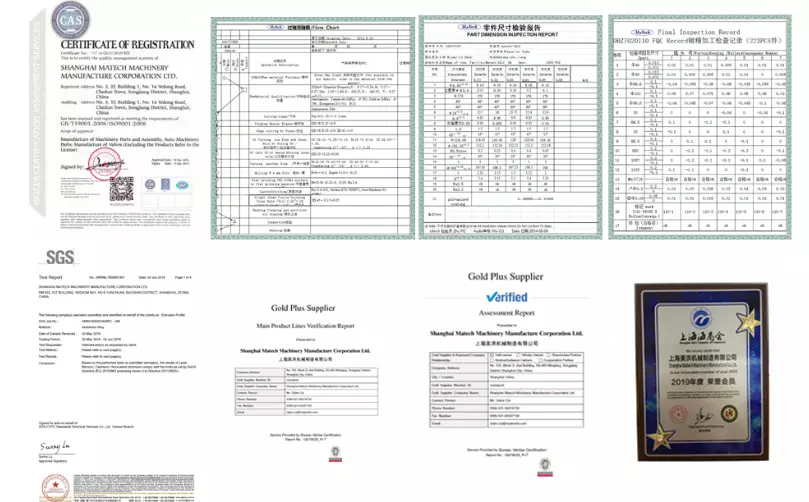

Our Advantages

Core Competence

1. Over 15 years professional manufacture experience. → We know better to your needs.

2. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow

analysis, Trial & mass production to Final assembly & shipment. → To ensure you get finished products with good assembly function.

3. High skilled and well-trained working team under good management environment. → To make sure high quality of your products.

4. Large and strong production capacity. → To meet your high demands very well.

5.Best price based on same quality requirements. →To help your project with most economical solution.

6. We have very strict quality control process included IQC/IPQC/FQC/OQC. → To deliver the qualified products for you.

7.Reliable Package & flexible in-time delivery. →To guarantee the product are well received in your side.

8. 24 hours on-line service with quick response. → To support your any inquiry or question.

Packing & Delivery

Hot Searches