- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Heating Power (kW):

-

120 kW

-

Air Comsumption(L/min):

-

20 L/min

-

Water Comsumption(L/min):

-

20 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FUSHI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*6*2.8m

-

Weight (T):

-

18 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Foaming Machine, Vacuum Forming

-

Max forming area:

-

1100mmx1000mm

-

Production efficiency:

-

3 - 5 seconds/mould

-

Forming pressure:

-

20t (adjustable)

-

efficiency:

-

3 - 5 seconds/mould

-

Products:

-

Lunch box,plate,tray and so on

-

Delivery time:

-

60 working days

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

1100 mm

-

Forming Length (mm):

-

1450 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Heating Power (kW):

-

120 kW

-

Air Comsumption(L/min):

-

20 L/min

-

Water Comsumption(L/min):

-

20 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FUSHI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

22*6*2.8m

-

Weight (T):

-

18 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Type:

-

Foaming Machine, Vacuum Forming

-

Max forming area:

-

1100mmx1000mm

-

Production efficiency:

-

3 - 5 seconds/mould

-

Forming pressure:

-

20t (adjustable)

-

efficiency:

-

3 - 5 seconds/mould

-

Products:

-

Lunch box,plate,tray and so on

-

Delivery time:

-

60 working days

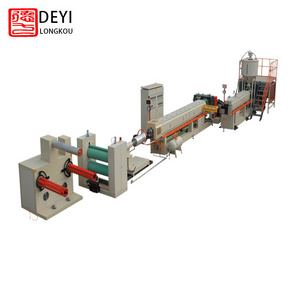

ps foam food box making machine

take away food tray machine Mainly including three main parts as below 1,2,3.

1. PS foam sheet extruder: make PS foam sheet from raw material

take away food tray machine produce PS foam sheet, which is a kind of new-type packing with the features of shock proofing, sound insulating, heat preservation, damp proof, safety, and good plasticity. It is used widely in the packing of food, fruit, electronic product, daily necessities, hardware product, advertisement plate, etc.

More details of equipment:

1.Shaping part:

2.Extruder head:

3.Pulling and winding part:

2. Fully auto forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box etc (we can design mould according to customer requirements)

1.Unwinding part, 2.Molding part, 3.Stacking part

3. Plastic recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again

Applications of ps foam food container machine

Export Standard Packing for epe pe ps foam net extrusion making machine

Why choose us We manfacture and supply

- epe foam net machine

- epe foam sheet machine

- epe foam tube machine

- pe foam cap liner machine

- ps foam plate making machine

- fruit washing and grading machine