- Product Details

- {{item.text}}

Quick Details

-

Table Size:

-

10.5M*2.0M

-

Overall Dimensions:

-

10.5*2.0*1.4m

-

Weight:

-

2000 kg

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

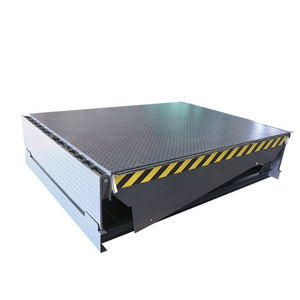

adjustable loading dock ramp

-

Platform size:

-

10.5*2.0 m

-

Lifting Height:

-

0.9-1.8M

-

Load capacity:

-

6-15 ton

-

Tyre:

-

2 pieces

-

Control:

-

Hydraulic Control

-

Power:

-

Manual Power

-

color:

-

Customized Color

-

Guard rail:

-

1.1M height

-

Type:

-

Mobile Type

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China

-

Min. Lifting Height:

-

0.9M

-

Table Size:

-

10.5M*2.0M

-

Overall Dimensions:

-

10.5*2.0*1.4m

-

Weight:

-

2000 kg

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

adjustable loading dock ramp

-

Platform size:

-

10.5*2.0 m

-

Lifting Height:

-

0.9-1.8M

-

Load capacity:

-

6-15 ton

-

Tyre:

-

2 pieces

-

Control:

-

Hydraulic Control

-

Power:

-

Manual Power

-

color:

-

Customized Color

-

Guard rail:

-

1.1M height

-

Type:

-

Mobile Type

Products Description

Warehouse Hydraulic Mobile Adjustable Container Loading Yard Dock Ramp

Mobile loading dock ramp is cargo handing auxiliary equipment matched with a forklift, the height can be adjust according to the level of car, the forklift can directly bulk cargo handing through the machine into the truck. Only one worker can realize fast loading and unloading of goods,It is enables to reduce a large number of labor, improve work efficiency to obtain greater economic benefits.

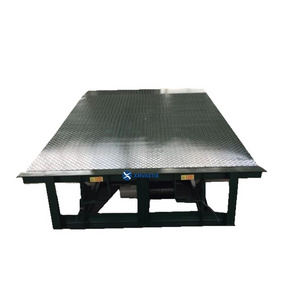

Features

1 table table with special antiskid Steel Grate has reliable strength, can ensure long-term use without deformation, its diamond mesh structure, fully ensure the excellent anti-skid performance, so that forklift has better climbing , even in rain, snow weather, still ensure normal use.

2. The chain of adjustable length can hook the truck conveniently, so that the boarding bridge and the truck are always close together

3. Using hand hydraulic pump action power, without external power supply can easily achieve the height adjustment of the boarding bridge

4. Equipped with brake pad can effectively prevent truck loading and unloading is the transfer of the boarding bridge

2. The chain of adjustable length can hook the truck conveniently, so that the boarding bridge and the truck are always close together

3. Using hand hydraulic pump action power, without external power supply can easily achieve the height adjustment of the boarding bridge

4. Equipped with brake pad can effectively prevent truck loading and unloading is the transfer of the boarding bridge

Products Advantages

Technical parameters

|

Model

|

Adjust lifting height range

|

Loading capacity

|

Platform size

|

Overall Dimension

|

|

LSDCQY6-0.9

|

0.9-1.8m

|

6 ton

|

10.5*2.0 m

|

10.5*2.0*1.4m

|

|

LSDCQY8-0.9

|

0.9-1.8m

|

8 ton

|

10.5*2.0 m

|

10.5*2.0*1.4m

|

|

LSDCQY10-0.9

|

0.9-1.8m

|

10 ton

|

10.5*2.0 m

|

10.5*2.0*1.4m

|

|

LSDCQY12-0.9

|

0.9-1.8m

|

12 ton

|

10.5*2.0 m

|

10.5*2.0*1.4m

|

|

LSDCQY15-0.9

|

0.9-1.8m

|

15 ton

|

10.5*2.0 m

|

10.5*2.0*1.4m

|

Operation

1. Fasten the return vavle and press the handl to move the ramp over the truck soleplate. Unfold the landing legs to working height.

2. Drive the car under the plate.

3. Release the return valve, and the ramp will fall down onto the afterbody of the truck, then fasten the ramp and the truck with the chain. The hyraulic system and the tyres of ramp do not carry the weight.

4. Operating starts.

5. When the operation finishes, untie the fixing chains. Lifting the ramp by the handle stick, and then drive out the truck.

6. Uplifting the after body of the ramp to move around hang on the truck.

Product packaging

3 sets can be loading into 40ft container , 5 sets can be loading into 40 HQ

Why Choose Us

Shandong Lift Star Heavy Industry Co.,LTD has many years experience in production of self-propelled scissor lift table, mobile scissor lift table, stationary scissor lift table, Aluminum alloy lift table, hydraulic cargo lift, mobile and fixed dock leveler. Our machine is export to more than 20 countries and received good feedback from customers.

The modern advanced CNC assembly line workshop strictly tests the advanced production technology from the purchase of raw materials to cutting, rust removal, welding, plastic spraying, assembly, commissioning, quality inspection and layer by layer, so as to ensure the safety, stability and durability of the equipment.

FAQ

1.What's the payment terms ?

T/T, L/C and other payment terms could be accept

2.What's the delivery term?

At most of time, the delivery time is 15-20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

3.How about your warranty?

Generally, our warranty is two year. Within the warranty period, we can offer technique support, Feedback to you within 24 hours and help you to repair your problem controller freely, even it's not from our factory

4. What’s the service of the machine ?

1).24 hour’s technical support by email or calling

2).English manual and video tutorial

3).We will provide the consumable parts at an agency price

Packed by standard export wooden box for outside package and stretch film for inner package, it won't be damaged. We've delivered many testing machines abroad by sea or by air without damage.

4).24 hours on line service each day, free technical support.

Hot Searches