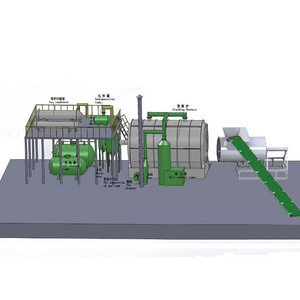

2/ Staring heating (4 hours): when feeding is finished, closed the feeding port and then ignites the heating system, the internal temperature goes up slowly in the first 2 hours.

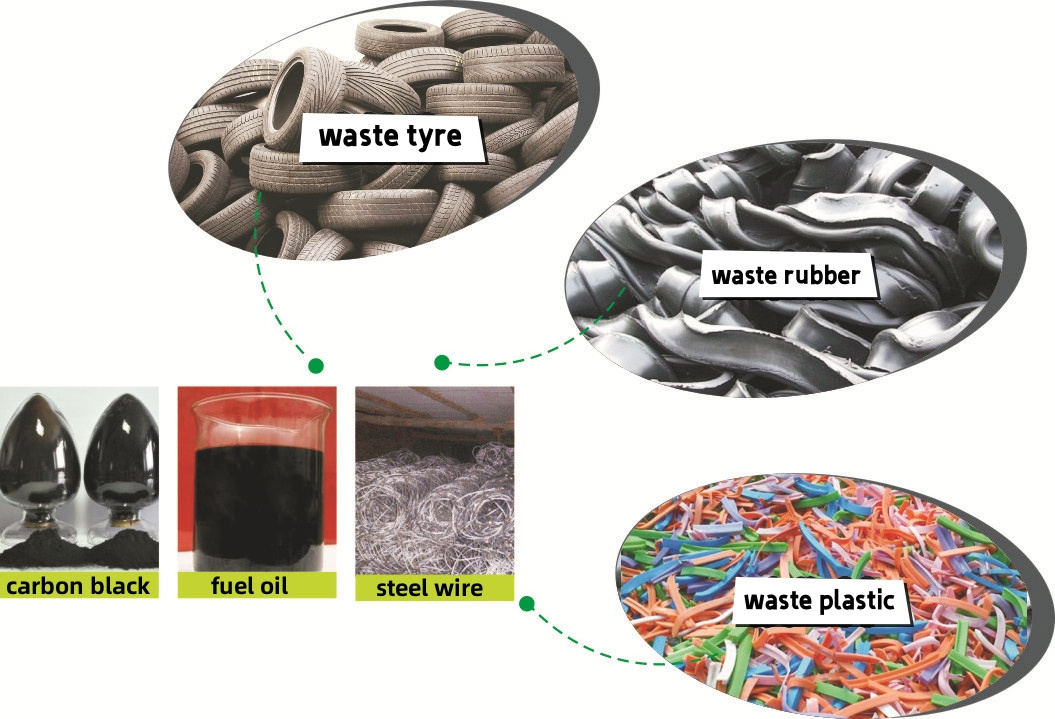

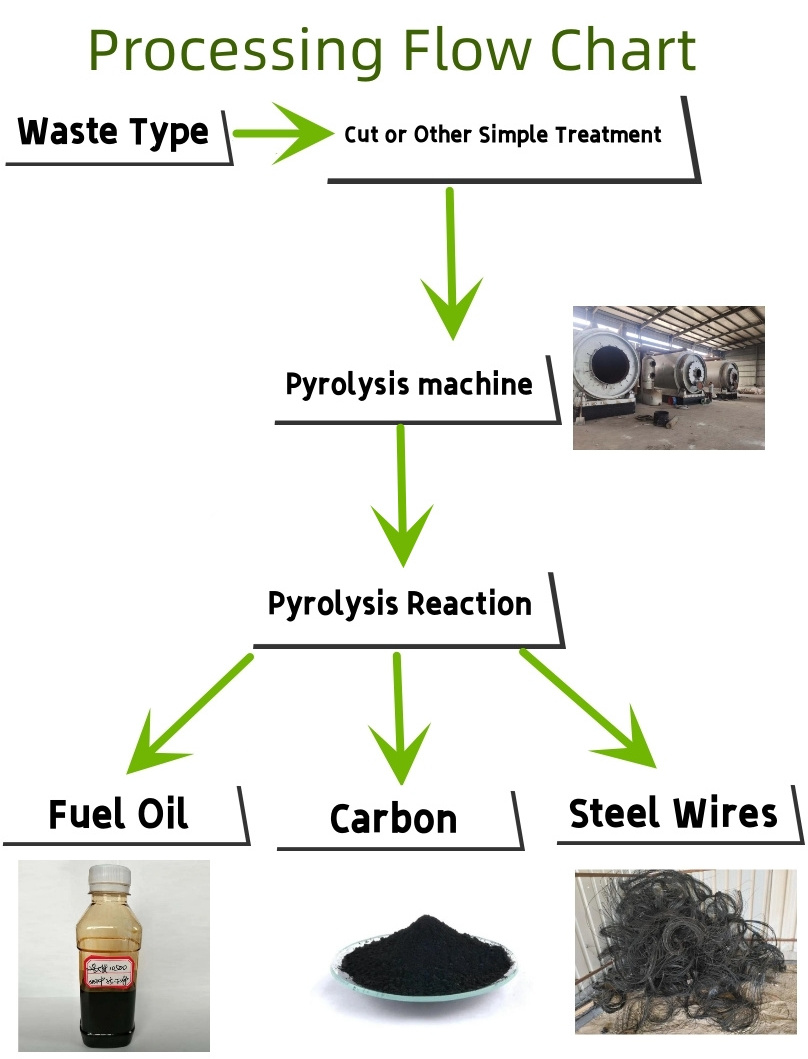

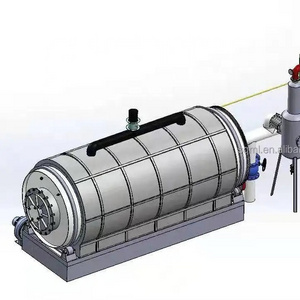

3/ Oil production(8 hours): Used tires break down into gas and solid state under pyrolysis reaction , the gas state entres condensing system, get liquified and becomes liquid fuel oil, the oil production lasts 8 hours, the solid state is carbon black and steel wire which stays inside pyrolysis reactor waiting for discharging.

3/ Oil production(8 hours): Used tires break down into gas and solid state under pyrolysis reaction , the gas state entres condensing system, get liquified and becomes liquid fuel oil, the oil production lasts 8 hours, the solid state is carbon black and steel wire which stays inside pyrolysis reactor waiting for discharging.

4/ Cooling down(8 hours): when oil production is finished, leaves the machine to coll down for 8hours before discharge.

5/ Discharging carbon black &steel wire(2hours): discharge carbon black from reactor by conveyor, discharge steel wire mass from reactor by winch.

5/ Discharging carbon black &steel wire(2hours): discharge carbon black from reactor by conveyor, discharge steel wire mass from reactor by winch.