- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.1KW

-

Weight:

-

690 kg

-

Dimension(L*W*H):

-

2630x1150x770mm

-

Description:

-

Cotton cake oil purificatioin filter press machine

-

Plate size:

-

500mm

-

Frame thickness:

-

50mm

-

Filter pressure:

-

≤2Mpa

-

Plate quantity:

-

22pcs

-

Max.pressure inner frame:

-

3kg/cm2

-

Volume inside frame:

-

216L

-

Flow:

-

87L/min

-

Motor speed:

-

1460r/min

-

Steady pressure:

-

12Mpa

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Toper

-

Voltage:

-

380V/400-450V

-

Power:

-

1.1KW

-

Weight:

-

690 kg

-

Dimension(L*W*H):

-

2630x1150x770mm

-

Description:

-

Cotton cake oil purificatioin filter press machine

-

Plate size:

-

500mm

-

Frame thickness:

-

50mm

-

Filter pressure:

-

≤2Mpa

-

Plate quantity:

-

22pcs

-

Max.pressure inner frame:

-

3kg/cm2

-

Volume inside frame:

-

216L

-

Flow:

-

87L/min

-

Motor speed:

-

1460r/min

-

Steady pressure:

-

12Mpa

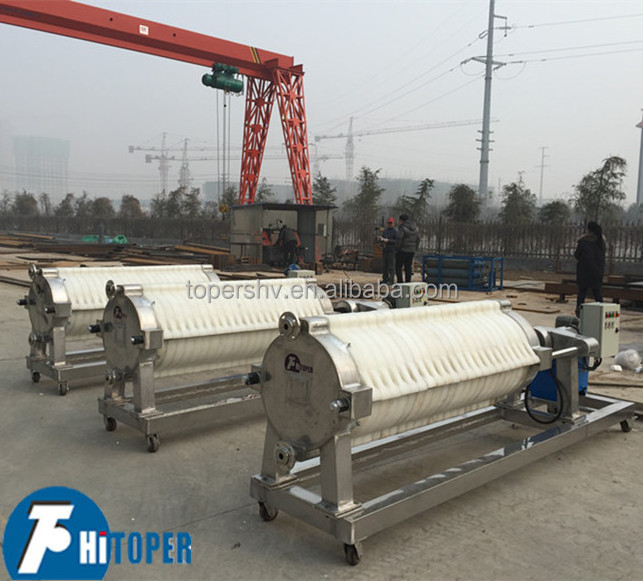

Overview of the Cotton cake oil purificatioin filter press machine

RNA gelatin use cotton cake filter press using recycled fiber material as filter media to remove traces of oil in the liquid material, mechanical impurities, suspended complexes and other impurities, so that filtered liquid clear and transparent.

Use and characteristics of the Cotton cake filter press machine

The company produces cotton cake frame filter machine is also suitable for liquid purification and filtration.In the chemical industry, metallurgy, pharmaceutical, food and other industries widely be used.

This unit has a large filter area, convenient operation and maintenance of the characteristics ,

the machine frame with a circular structure, a square structure of the frame than the filter performance is more excellent, aircraft aluminum frame material and reinforced polypropylene two kinds of and can increase the number of frame can be reduced, can be applied to different liquid filtration.

Basic technical data about the Cotton cake oil purificatioin filter press machine ,honey filter press

|

Filter area (m2) |

Plate size (mm) |

Frame thickness (mm) |

Filter pressure (MPa) |

(PCS) Plate quantity |

Max. pressure Inner frame (kg/c m2) |

|

8 |

500 |

50 |

≤2 |

22 |

3 |

|

Volume inside Frame (L) |

Dimension (L×W×H) (mm) |

flow (L/min) |

Motor power (kw) |

Motor speed (r/min) |

Steady Pressure (MPa) |

|

216 |

2630×1150×770 |

87 |

1.1 |

1460 |

12 |

Application:

It is used in fermentation ,enzymes,RNA gelatin,food and beverage ,and other high precision requirement industries.

The bascic structure of the cotton cake filter press machine :

Our manufacturing base of filter equipment mainly produce full automatic or semi-automatic membrane filter press, recessed filter press, belt filter press, centrifuge, etc. All these products are widely used in mining, metallurgy, petroleum, chemical, medicine, textile, printing and dyeing, paper making, food, alcohol, inorganic salt, coal washing, and waste water processing industry.

Our products has passed ISO9001 International Quality Management System Certification and is exported to about more than 50 countries and area. We have won good reputation depends on our best qualified products and after-sales service. Warmly welcome new and old friends all over the world to come our company for good cooperation with each other!

FILTER PRESS SERIES:

Filter presses can be divided into plate and frame type and are used for solidliquid separation of various suspending liquid in intermittent pressure filtration. Filter plates are pressed by pressing devices and suspending liquid is pumped into the filter chamber. Solid particles and separated through filter cloth. The products are simple in structure but good in separating effects, convenient in use, and widely applicable to mining, metallurgy, petroleum, chemical, medicine, textile, printing and dyeing, paper making, foodstuff, alcohol, inorganic salt, coal washing, dyestuff and sewage treatment industries.

Products Series:

Our company produces various models of recessed plate and plant-frame mechanical filter press, hydraulic filter press, membrane filter press, sealing a box pressure filter and full-automatic filter press and filter press spare parts.

1, Models include: 320, 450, 630, 800, 1000, 1250, 1500 and 2000 etc.

2, Filtration area up to 2000m2

3, Filter plate materials: cast iron, rubber, reinforced polypropylene (plastic), glass fiber polypropylene

etc.

4, Flow forms: open flow, close flow, washable, non-washable, middle feeding and corner feeding etc.

5, Filter plate pressing modes: manual screw pressing, electric mechanic pressing and hydraulic cylinder pressing. Special filter press can be made on request.