- Product Details

- {{item.text}}

Quick Details

-

Power Source:

-

Mechanical

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customer's Requirement

-

Application:

-

powder metallurgy ,fine ceramics, magnetic and relevant industries

-

Raw material:

-

Fe Cu Al base,hard alloy,magnetic,ceramic,electrical carbon

-

Delivery time:

-

5 months

-

Usage:

-

metal, ceramic.....

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CPCP

-

Weight (KG):

-

1000

-

Power Source:

-

Mechanical

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customer's Requirement

-

Application:

-

powder metallurgy ,fine ceramics, magnetic and relevant industries

-

Raw material:

-

Fe Cu Al base,hard alloy,magnetic,ceramic,electrical carbon

-

Delivery time:

-

5 months

-

Usage:

-

metal, ceramic.....

Technical Specification

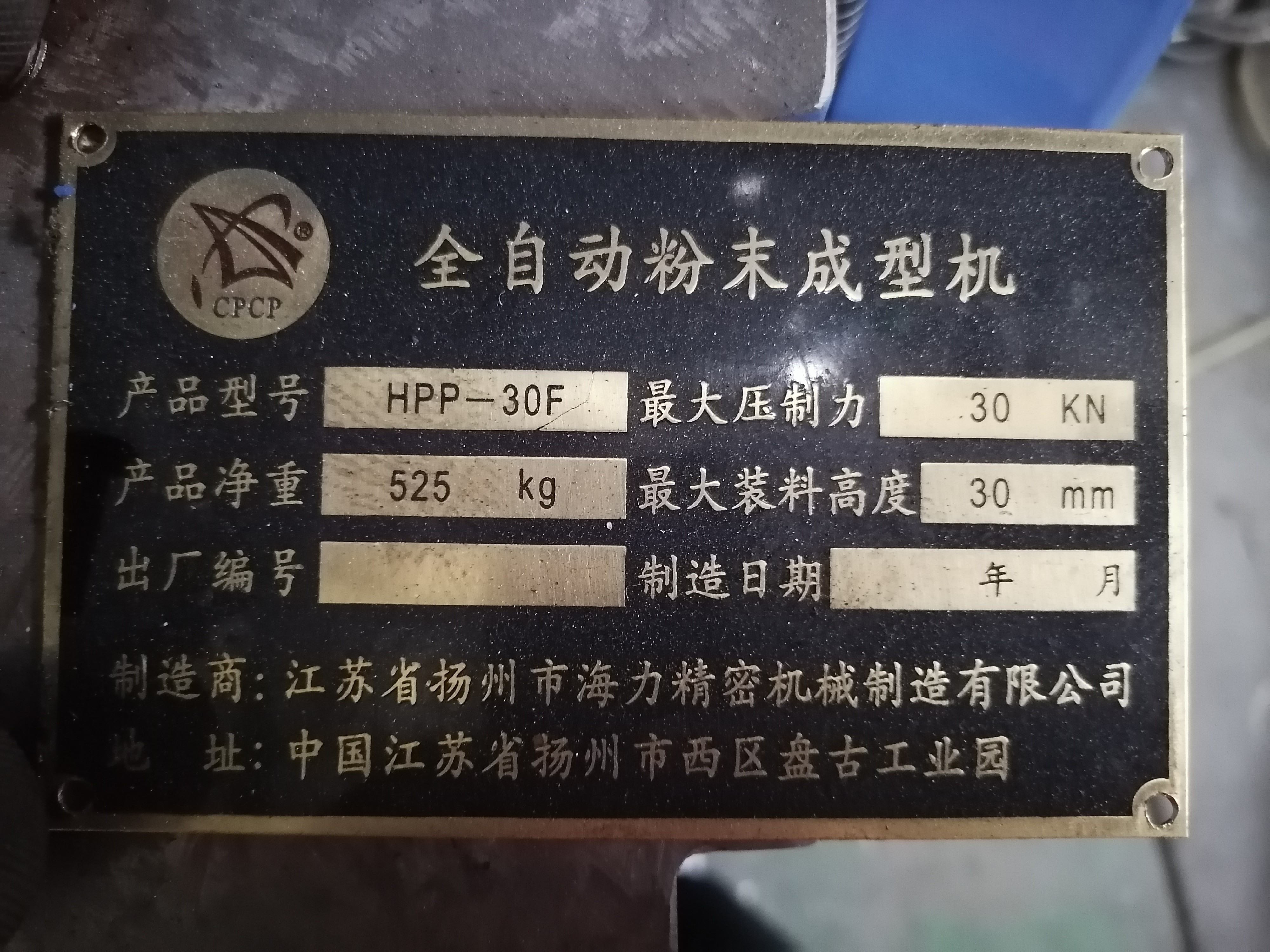

HPP-30F powder compacting press machine for powder metallurgy

|

Max pressing capacity(KN)

|

30

|

|

Upper punch stroke(mm)

|

48

|

|

Max filling height (mm)

|

30

|

|

Stroke rate(r/min)

|

16-55

|

|

Powder Hopper(L)

|

3.2

|

|

Worktable Height (mm)

|

1100

|

|

Motor powder(KW)

|

1.5

|

|

Weight of machine(KG)

|

525

|

|

Overall dimension(mm)

|

320*750*1750

|

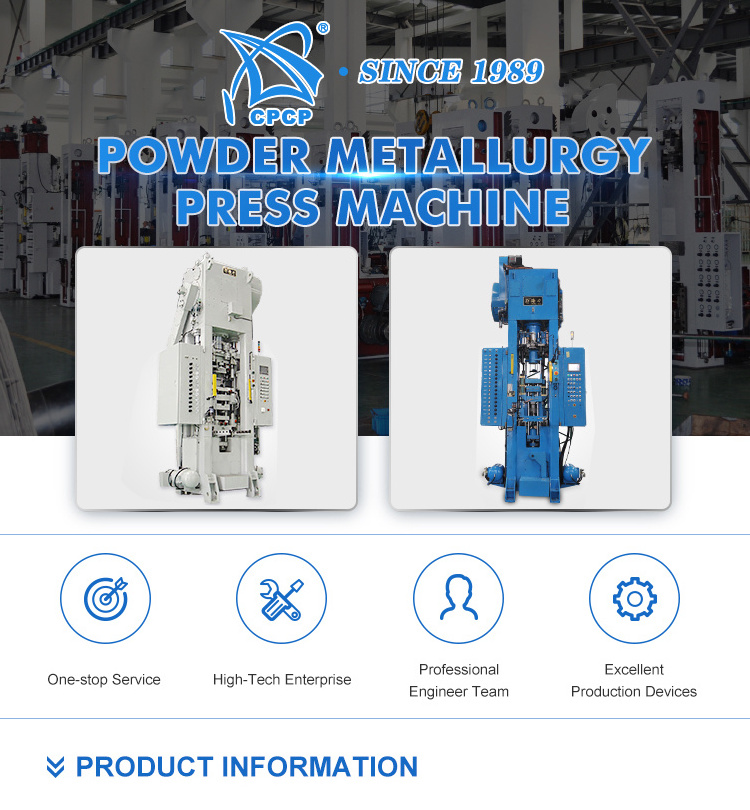

Our company already in powder metallurgy 30 years.It has 40,000 square meters area;

the construction area is 26, 000 square meters.

HPP-P, HPP-S, HPP-F, HPP-N, HPP-H, HPP-T series full-automatic powder compacting press machine and HSP-J, HSP-H, HSP-P series sizing machine which widely used in powder metallurgy, hard alloy, magnetic material, fine ceramic, electrical carbon and so on.

They are ranged from 1T to 850T.

They are ranged from 1T to 850T.

We have vertical boring and milling machine center, turning machine center, screw grinder, deep hole grinder, ultra precision cylindrical grinder, ultra precision surface grinder and other key equipment;the

three-coordinates gauging machine and other precision inspection equipment; and CNC machine,

three-coordinates gauging machine and other precision inspection equipment; and CNC machine,

CNC milling machine, large housing pane, large planer-type milling machine and other about 160 sets of metal cutting machines.

Step 1: Our technicians check all the press machine specification first whether meet

the requirements.

Step 2: Customer come to factory with mould and powder to test the press machine operation.

Step 3: Our technicians go to customer factory to commissioning the press machine when machine arrived.

Our technicians also provide the free press machine training course.

Step 3: Our technicians go to customer factory to commissioning the press machine when machine arrived.

Our technicians also provide the free press machine training course.

Our company has been through the ISO9001 international quality system certification and European CE certification.

We have 12 patents, 37 utility model patents, 1 appearance patent.

Title goes here.

Each year, we attend the Asia, Europe and the World powder metallurgy conference , Auto expo, Forming exhibition,and other related exhibition all over the world.

Hot Searches