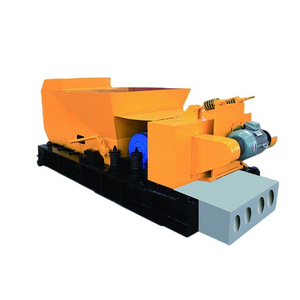

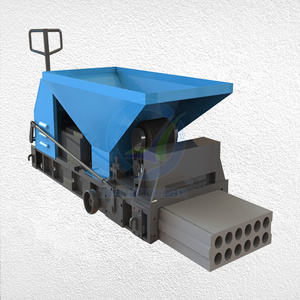

The automatic vertical-type concrete panel machine

(HONGFA Exclusive Product) absorbs the advantages of vertical-type and horizontal-type machines.

.

It doesn't need the concrete slurry pumping machine, the concrete slurry is poured directly from the mixer, which is much faster than the pumping machine.

.

Higher capacity and efficiency than the horizontal type, almost three times higher than a horizontal forming machine.