- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Paddy Rice De-stoner

-

Product Name:

-

Engineers Available To Service Machinery Overseas

-

Rated Capacity:

-

Paddy Separator Machine Grain Seed Cleaning Machine Gravity Table

-

Processing Material:

-

Seeds, Cereal Grains, Beans, Sesame, Oil seeds, Garden Seeds etc.

-

Total Power:

-

~1.5 kW

-

Where to Use:

-

Rice, Flour Mill, Seed Cleaning Plant, Coffee, Malt Factory

-

Destoner Screen Width:

-

600~2000mm

-

Dust Removal System:

-

Blower, Dust Collector, Air Pipes

-

Cleaning Efficiency:

-

99.99%

-

Supply range:

-

1~20 t/h seed cleaning plants

-

Body material:

-

Cold Caron Steel

-

Certification:

-

ISO9001:2008

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

COFCO - MAOSHENG

-

Type:

-

Grain Seed Cleaning Machine

-

Use:

-

Paddy Rice De-stoner

-

Product Name:

-

Engineers Available To Service Machinery Overseas

-

Rated Capacity:

-

Paddy Separator Machine Grain Seed Cleaning Machine Gravity Table

-

Processing Material:

-

Seeds, Cereal Grains, Beans, Sesame, Oil seeds, Garden Seeds etc.

-

Total Power:

-

~1.5 kW

-

Where to Use:

-

Rice, Flour Mill, Seed Cleaning Plant, Coffee, Malt Factory

-

Destoner Screen Width:

-

600~2000mm

-

Dust Removal System:

-

Blower, Dust Collector, Air Pipes

-

Cleaning Efficiency:

-

99.99%

-

Supply range:

-

1~20 t/h seed cleaning plants

-

Body material:

-

Cold Caron Steel

-

Certification:

-

ISO9001:2008

KAIFENG HYDE MACHINERY CO., LTD.

MAOSHENG GROUP

u 50 YEARS MANUFACTURING EXPERIENCE SINCE 1976.

u CHINA TOP 10 GRAIN PROCESSING MACHINERY MANUFACTURING COMPANY.

u MEMBER OF 13 CHINA NATIONAL STANDARDS DRAFTER IN GRAIN PROCESSING INDUSTRY.

u 75 PATENTED TECHNOLOGIES AND PRODUCTS.

u 600,000 SQUARE METER PRODUCTION AREA.

u OVER 100 EXPERIENCED ENGINEERS, RESEARCH STAFF AND TECHNICIANS.

u STATE-OF-THE-ART FACILITIES. ADVANCED IMPORTED CNC MACHINES FOR FUNCTION PARTS.

u FULL RANGE OF SERVICE, FROM SINGLE MACHINE TO TURNKEY SYSTEMS IN GRAIN AND FLOUR INDUSTRY.

u MACHINERY AND EQUIPMENT QUALITY TESTED BY DOMESTIC AND GLOBAL MARKET, RICH INSTALLATION AND TROUBLE-SHOOTING EXPERIENCE.

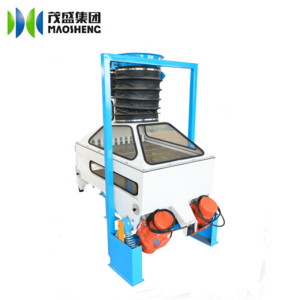

Product Overviews:

TQSF125B De-stoner

Structure Drawing s:

u TQSF De-stoner Is A Grading And Stone Removal Of Grain Particles (Rice, Wheat, Beans, Corn, Etc.).

u TQSF De-stoner Has High Production Efficiency, Good Performance In Classification, Stone Removal And Impurity Removal, Low Energy Consumption, Low Noise, No Dust, Easy Operation And Operation Adjustment, Simple Maintenance.

(1). The fully sealed vibrator (A) is supported by two sets of "eight" springs (B) on both sides of the rear end and an adjustable support rod (C) in the middle of the front end.

Two vibrating motors (L) are bolted side by side on the circular shaft at the rear end of the vibration body. The two motors rotate in the direction of each other and drive the vibration body to reciprocate linear vibration.

(2). Front at the top of the machine for the material import (D), by the fixed on the supporting frame (M) of the plate will be hold, are connected to the chute feed inlet top (upper inlet as buffer hopper is best), the bottom through the soft tube is connected to a feed box (E).Container (E) is located in the inlet below, fixed on the vibrating body, in the box is equipped with adjustable spring offered material baffle to control the material flow, material box containing organic glass observation window (F), in order to observe the condition of material.

All equipped with large observation window suction hood (G) is installed in the upper body vibration, suction duct above the suction hood (H) on the hose (J) connected to the suction cover, inside the suction duct is equipped with an external handle can be adjusted by controlling the butterfly throttle.

(3). The machine base (K) directly supports the vibration body (A), the support frame supports the suction pipe (H) and the feed pipe (D) and is fixed on the base (K).

(4). Vibration in the body is equipped with two layers of withdrawable type mesh (N) and (O), the upper mesh (N) three section of the screen surface, the first paragraph for spring steel wire weaving nets, the second for the long hole sieve plate, the third paragraph as the round hole sieve plate, this layer mesh for material classification, classification of material flow (light) from the rear of vibration body eduction closed, light impurity by suction duct suck.Lower mesh mainly to remove sand, clay pieces, pass the screen mesh of sandstone, clay pieces by vibration devices for the two horns at the stone mouth discharge, through the screen mesh of sand, dirt and debris discharge closed directly, go after the stone material flow (heavy) by the vibrating body back-end out of food.

Technical Specification :

Notes:

Whole Cleaning Processing Plant:

Whole Plant Drawings:

- Turkey Project Machine And Service Available For Rice, Wheat, Maize, Buckwheat, Barley Etc.

- Building Structure And Steel Structure. :

Grain and Seed Cleaning Machine:

Pre-cleaners, Fine Cleaners, Rotary Cleaners, Seed Graders, Seed Gravity Separators, Indented Cylinder, Wheat Paddy De-awner, Destoner, Vibration Cleaner, Rotary Cleaner, Air Aspirator, Cyclone Dust Collector, Seed Treater, Seed Dryers, Elevators And Conveyors, Auto-packing Scales.

5XZ Gravity Table 5X Air Screen Seed Cleaner TQSF De-stoner

HZZD Large Rotary Cleaner TQLZ Vibration Cleaner 5XW Indented Cylinder

MAOSHENG GROUP

Sales Manager

David

Phone: +86 18703698486

WhatsApp: +86 18703698486