- Product Details

- {{item.text}}

Quick Details

-

Rolling Speed (m/min):

-

4 - 5

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

MIHATING

-

Year:

-

2020

-

Weight (KG):

-

2000 KG

-

Motor Power (kw):

-

4 kw

-

Raw Material:

-

Plate Rolling

-

Application:

-

Steel Plate Sheet Rolling

-

Rolling materials:

-

Metal Sheet Plate

-

Roller quantity:

-

3roller

-

Control system:

-

PLC+Numerical Control Angle

-

Pre-bending thickness:

-

3.5~40 Mm

-

Bending machine application:

-

Steel Sheet Rolling Machine

-

Max rolling thickness:

-

4-60mm

-

Up roller diameter:

-

160mm

-

Color:

-

Customizable

Quick Details

-

Max. Working Length (mm):

-

2500 mm

-

Max. Plate Thickness (mm):

-

6 mm

-

No. of Roller:

-

3

-

Rolling Speed (m/min):

-

4 - 5

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

MIHATING

-

Year:

-

2020

-

Weight (KG):

-

2000 KG

-

Motor Power (kw):

-

4 kw

-

Raw Material:

-

Plate Rolling

-

Application:

-

Steel Plate Sheet Rolling

-

Rolling materials:

-

Metal Sheet Plate

-

Roller quantity:

-

3roller

-

Control system:

-

PLC+Numerical Control Angle

-

Pre-bending thickness:

-

3.5~40 Mm

-

Bending machine application:

-

Steel Sheet Rolling Machine

-

Max rolling thickness:

-

4-60mm

-

Up roller diameter:

-

160mm

-

Color:

-

Customizable

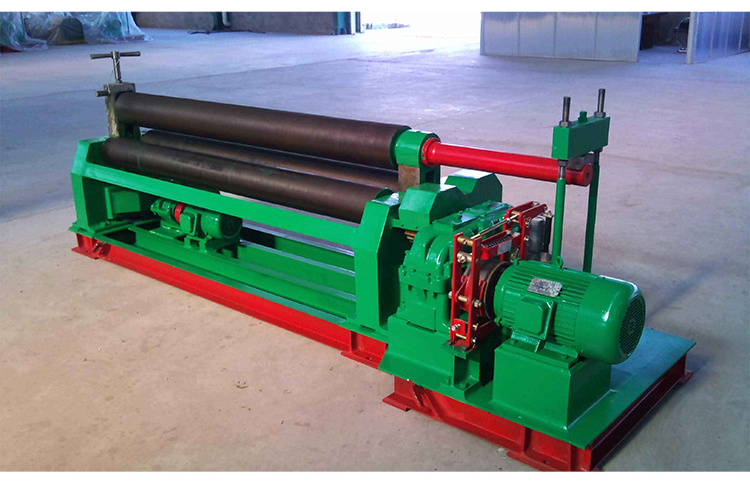

Product Description

W11-25*2500mm Series Mechanical Type 3 Rollers Rolling and Bending Machine/ Pipe Forming Machine/Sheet Metal Bending Machine

This belongs to three roller plate rolling machine,up roller is fixed and it is the main drive,hydraulic motor driven by variable

speed drive gear up and down roller belt drive, to provide torque for the roll sheet; under the roller moves vertically through

the hydraulic pressure acting on the piston of hydraulic cylinder obtained in order to clamp plate for hydraulic transmission;

This belongs to three roller plate rolling machine,up roller is fixed and it is the main drive,hydraulic motor driven by variable

speed drive gear up and down roller belt drive, to provide torque for the roll sheet; under the roller moves vertically through

the hydraulic pressure acting on the piston of hydraulic cylinder obtained in order to clamp plate for hydraulic transmission;

the down roll of the sides with side roller and cylinder driven by oil.The machine advantage of end plate bending(pre-bending) androlling can be conducted on the same machine Structure and main parts: This equipment composed of work frame , upper roll device ,main drive device, down roll device, side roll device, overturn device ,hydraulic system(parts) , electricity system(parts), and lubricate device .

Work frame:

Body from the base, a fixed side frame and the tip side of the rack, and each part is steel welded structure. Were fixed with bolts on both sides of the rack in the base and sides of the rack will be used to connect beams

connected to rigidity good. Both sides of the rack up roller and side rollers with movement of rail, fixed on the side of the rack with roller bearing for half of the closed frame structure, has overturned side rack shelf support devices.

connected to rigidity good. Both sides of the rack up roller and side rollers with movement of rail, fixed on the side of the rack with roller bearing for half of the closed frame structure, has overturned side rack shelf support devices.

Coil force in the process of both sides of the rack by the bear from the base not only supports the weight of the machine to ensure the accuracy of the role of equipment, but also enables a torque between the drive and chassis balance, and will join into one machine. In the now traditional large-scale four-roller bending machine body and the main gear is separate from the base installation.

Feature:

This kind of plate bending machine belongs to 3 roller symmetrical mechanical structure.The top roller moves up and down at the central part of the two bottom rolls.Screw nut and worm gear both play role of transmission.Two bottom rolls act as main driving rolls.Through the meshing,they are able to rotate between the output gear of the gearbox and the bottom roller,so as to supply the torque to bend plate.This type of machine does well in compact structure,easy operation and convenient maintenance.

This kind of plate bending machine belongs to 3 roller symmetrical mechanical structure.The top roller moves up and down at the central part of the two bottom rolls.Screw nut and worm gear both play role of transmission.Two bottom rolls act as main driving rolls.Through the meshing,they are able to rotate between the output gear of the gearbox and the bottom roller,so as to supply the torque to bend plate.This type of machine does well in compact structure,easy operation and convenient maintenance.

Specification

|

item

|

value

|

|

Material / Metal Processed

|

Aluminum, Carbon Steel, ALLOY, Stainless Steel

|

|

Max. Working Length (mm)

|

2500mm

|

|

Max. Plate Thickness (mm)

|

25mm

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pump

|

|

No. of Roller

|

3

|

|

Rolling Speed (m/min)

|

4-5

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

|

Anhui

|

|

Brand Name

|

MIHATING

|

|

Automation

|

Automatic

|

|

Extra Services

|

Machining

|

|

Certification

|

ce

|

|

Year

|

2020

|

|

Weight (KG)

|

2000KG

|

|

Motor Power (kw)

|

4kw

|

|

Machine Type

|

Roller-Bending Machine

|

|

Key Selling Points

|

Multifunctional

|

|

Warranty

|

1 Year

|

|

|

Online support, Video technical support

|

|

After Warranty Service

|

Video technical support, Online support

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Home Use

|

|

Local Service Location

|

None

|

|

Showroom Location

|

None

|

|

Raw Material

|

Plate Rolling

|

|

Application

|

Steel Plate Sheet Rolling

|

|

Rolling materials

|

Metal Sheet Plate

|

|

Roller quantity

|

3roller

|

|

Control system

|

PLC+Numerical Control Angle

|

|

Pre-bending thickness

|

3.5~40 Mm

|

|

Bending machine application

|

Steel Sheet Rolling Machine

|

|

Max rolling thickness

|

4-60mm

|

|

Up roller diameter

|

160mm

|

|

Color

|

Customizable

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches