- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Bag, Industry, Blanket, Shoes, Car, Garments processing-Lining, Garments processing-Interlining, Outdoor-Agriculture, Outdoor-Industry, Hospital, decoration

-

Weight:

-

150-680G/m2

-

Thickness:

-

Regular

-

Place of Origin:

-

Shandong, China, CN;SHN

-

Brand Name:

-

REGAL

-

Model Number:

-

Plain

-

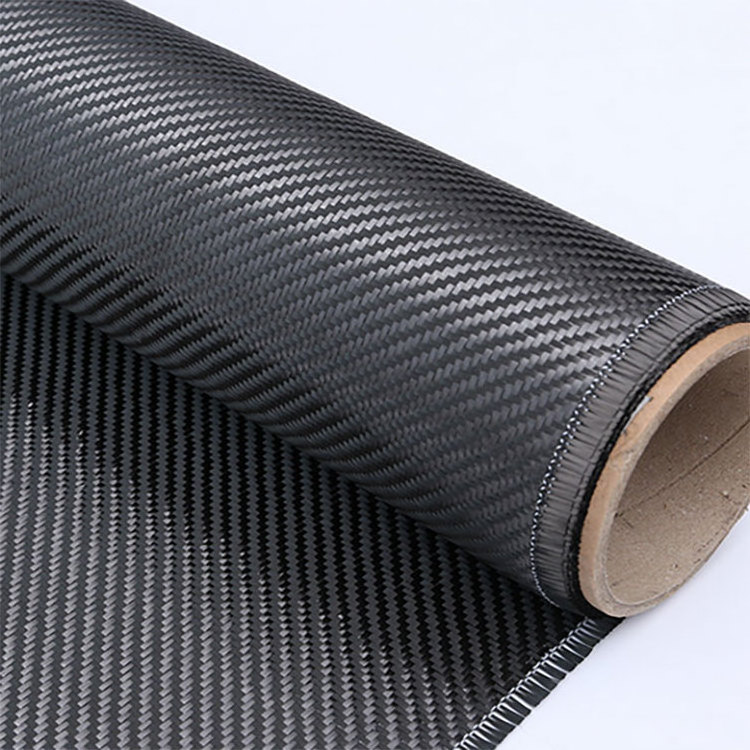

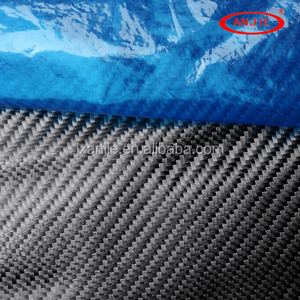

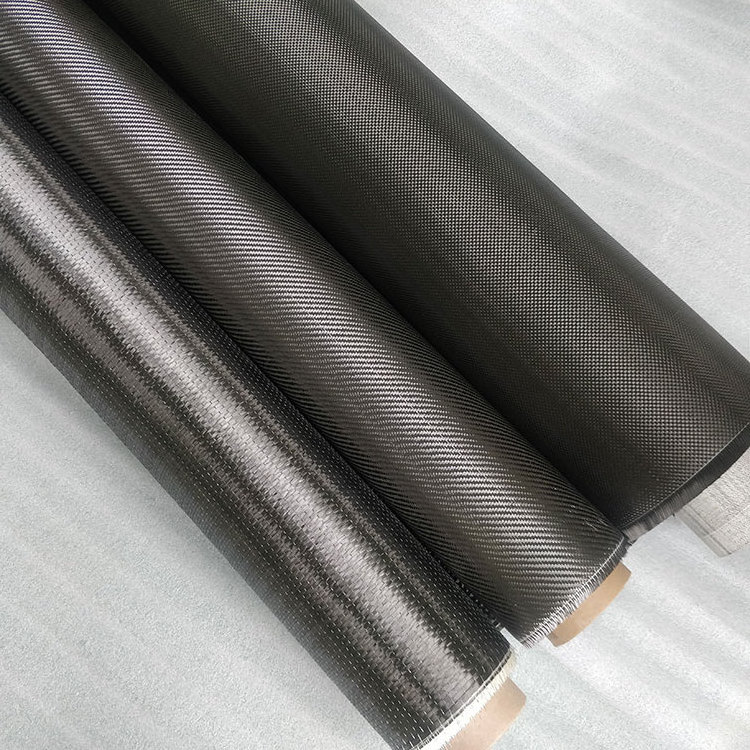

3k twill carbon fiber:

-

3k 100 meter x 1m width Twill Woven Carbon Fiber Fabric Roll

-

Color:

-

Black

-

Tow Size:

-

3K/6K/12K

-

Length:

-

100-400m

-

Product name:

-

carbon fiber fabric

-

Weave:

-

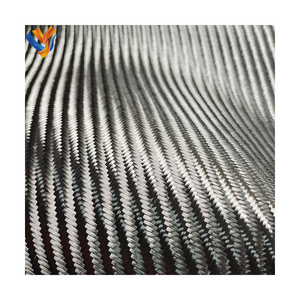

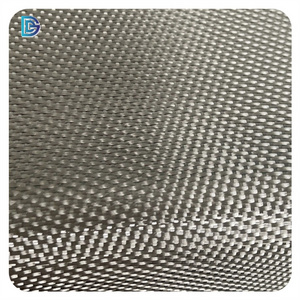

3K Plain / Twill

-

Yarn:

-

3K+1500D

-

Application:

-

Aerospace Industry

Quick Details

-

Pattern:

-

SOLIDS

-

Material:

-

100% Carbon Fiber

-

Feature:

-

Abrasion-Resistant, Waterproof, Anti-Static, Heat-Insulation, Anti Pill, Blackout, Brushed Sueded, DIMENSIONAL, Sustainable, Stretch, Anti-Fire

-

Use:

-

Bag, Industry, Blanket, Shoes, Car, Garments processing-Lining, Garments processing-Interlining, Outdoor-Agriculture, Outdoor-Industry, Hospital, decoration

-

Weight:

-

150-680G/m2

-

Thickness:

-

Regular

-

Place of Origin:

-

Shandong, China, CN;SHN

-

Brand Name:

-

REGAL

-

Model Number:

-

Plain

-

3k twill carbon fiber:

-

3k 100 meter x 1m width Twill Woven Carbon Fiber Fabric Roll

-

Color:

-

Black

-

Tow Size:

-

3K/6K/12K

-

Length:

-

100-400m

-

Product name:

-

carbon fiber fabric

-

Weave:

-

3K Plain / Twill

-

Yarn:

-

3K+1500D

-

Application:

-

Aerospace Industry

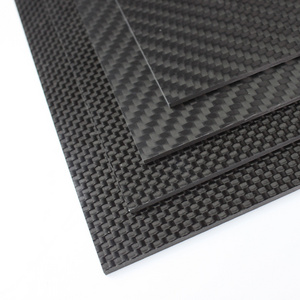

3k 100 meter x 1mwidth Twill Woven Carbon Fiber Fabric Roll

Product Description

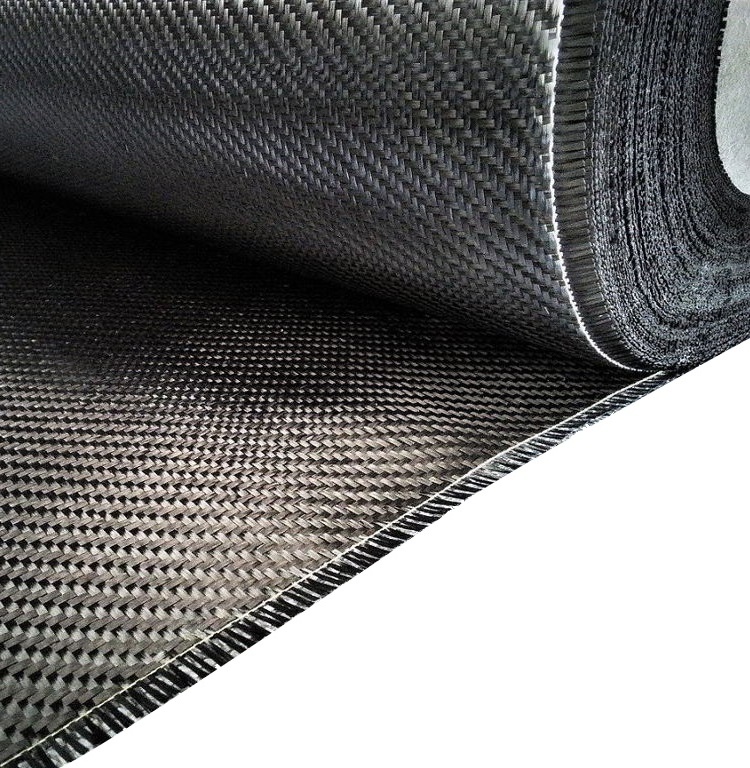

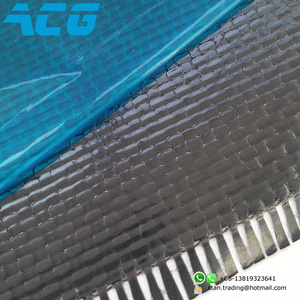

1K means 1 carbon yarn contains 1000 filaments, 2K means 2000 filaments, and so on. We have 1K/3K/6K/12K carbon fiber fabric. The

smaller K is, more complicated the production process is! so the small K carbon fiber fabric is more expensive.

The two-way cabon fiber fabric are woven with Plain and Twill style, we have 120gsm, 140gsm, 200gsm, 240gsm, 280gsm, 320gsm,

400gsm, 480gsm,640gsm for choosing.

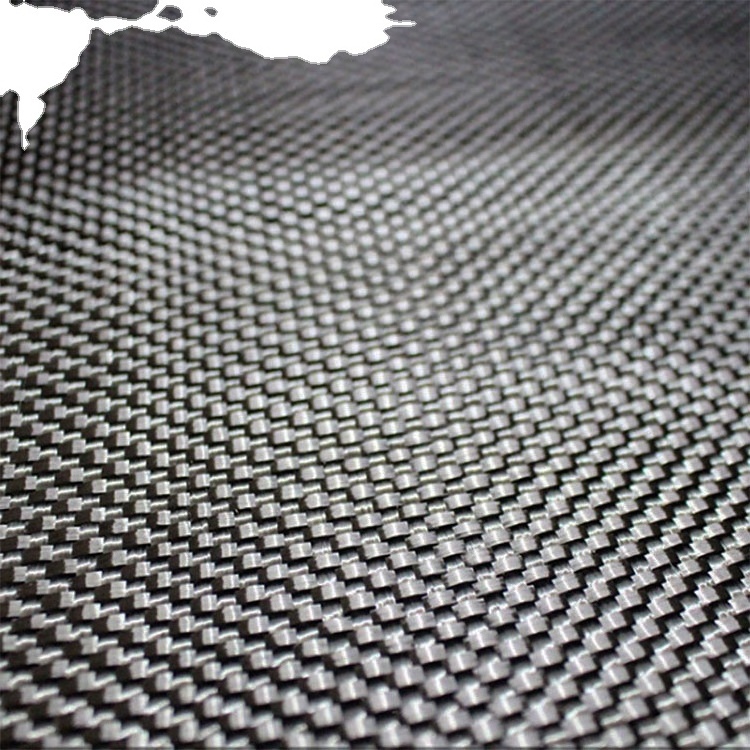

Some commonly used types of weave are twill, plain and satin. Compared with traditional meterial, carbon fiber fabric has many

advantages such as high stiffness, high tensile strength, low weight, high temperature tolerance and low thermal expansion. These

make the weight greatly reduced. Meanwhile, carbon fiber fabrics are compatible with various resin systems including epoxy,

polyester and vinyl ester resins.

With a light weight, high strength, high modulus, fatigue resistance, heat resistance, corrosion resistance, drug resistance,

electrical conductivity, X-ray penetrability, the carbon fiber fabrics are mainly used in aircraft, tail and body: auto engine,

synchronous, machine covers, bumpers, trimming ; Bicycle frames, faucets bat, the sound, Kayaks, skis, various models, skull,

building reinforcing, watches, pens, bags and so on.

smaller K is, more complicated the production process is! so the small K carbon fiber fabric is more expensive.

The two-way cabon fiber fabric are woven with Plain and Twill style, we have 120gsm, 140gsm, 200gsm, 240gsm, 280gsm, 320gsm,

400gsm, 480gsm,640gsm for choosing.

Some commonly used types of weave are twill, plain and satin. Compared with traditional meterial, carbon fiber fabric has many

advantages such as high stiffness, high tensile strength, low weight, high temperature tolerance and low thermal expansion. These

make the weight greatly reduced. Meanwhile, carbon fiber fabrics are compatible with various resin systems including epoxy,

polyester and vinyl ester resins.

With a light weight, high strength, high modulus, fatigue resistance, heat resistance, corrosion resistance, drug resistance,

electrical conductivity, X-ray penetrability, the carbon fiber fabrics are mainly used in aircraft, tail and body: auto engine,

synchronous, machine covers, bumpers, trimming ; Bicycle frames, faucets bat, the sound, Kayaks, skis, various models, skull,

building reinforcing, watches, pens, bags and so on.

Carbon Fiber Fabric is made of carbon fiber by woven unidirectional, plain weaving or twill weaving style. The carbon fibers we use contain high strength-to-weight and stiffness-to-weight ratios, carbon fabrics are thermally and electrically conductive and exhibit excellent fatigue resistance. When properly engineered, carbon fabric composites can achieve the strength and stiffness of metals at significant weight savings. Carbon fabrics are compatible with various resin systems including epoxy, polyester and vinyl ester resins.

|

Pattern

|

Plain / Twill / UD / Hexagon / Biaxial

|

|

Yarn

|

3K / 6K / 12K

|

|

Width

|

1000-1600mm

|

|

Length

|

100-400M

|

|

Density

|

200-680gsm

|

|

Thickness

|

0.25-0.64mm

|

Product Data

Related Products

Features

Application

Hot Searches