- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SCBN TOOLS

-

Model Number:

-

SNGX

-

Product name:

-

Brake Disc Cutting Tools

-

Material:

-

PCBN Brazed Inserts ;Carbide Inserts + Ceramic Inserts

-

MOQ:

-

10 pcs

-

Grade:

-

SBN850/SBN800

-

Brand:

-

SCBN TOOLS

-

Origin:

-

Zhengzhou Henan

-

Color:

-

Picture

-

OEM & ODM:

-

Support OEM

-

Quality:

-

High Qulity

-

Feature:

-

Hign Wear Resistance

Quick Details

-

Usage:

-

External Turning Tool

-

Hardness:

-

HRC90

-

Coating:

-

None

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SCBN TOOLS

-

Model Number:

-

SNGX

-

Product name:

-

Brake Disc Cutting Tools

-

Material:

-

PCBN Brazed Inserts ;Carbide Inserts + Ceramic Inserts

-

MOQ:

-

10 pcs

-

Grade:

-

SBN850/SBN800

-

Brand:

-

SCBN TOOLS

-

Origin:

-

Zhengzhou Henan

-

Color:

-

Picture

-

OEM & ODM:

-

Support OEM

-

Quality:

-

High Qulity

-

Feature:

-

Hign Wear Resistance

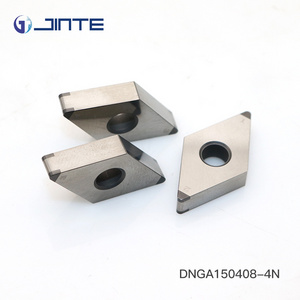

Best Cbn Insert Solid Cbn Insert For Cylinder Boring Machine Cbn Cutting Tools Insert SNGX For Turning

Product Introduction

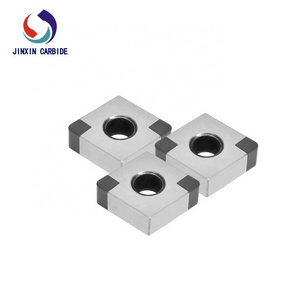

Carbide Inserts + Ceramic Inserts

Processing procedures:

Rough machining, Semi-finishing and finishing are completed on two machine tools respectively.

Disadvantages:

Double clamping, low processing efficiency, difficult to guarantee processing accuracy, low cutting efficiency of carbide coated blades, poor surface finish of brake disc, large cutting resistance, stress on the surface of castings, and large dimensional fluctuations.

PCBN Brazed Inserts

Processing procedures:

Rough machining and finishing machining are completed on two machine tools respectively.

Disadvantages:

Double clamping, low processing efficiency, difficult to guarantee processing accuracy, PCBN welding blade, complex installation and adjustment of the tool tip, multiple adjustments to the tool, difficult to guarantee the processing accuracy of the brake surface.

|

Processing No.

|

Processing Part

|

CBN Inserts Models and Grade

|

Suitable Tool Holder

|

Cutting Speed Vc

(m/min)

|

Feed Rate Fr(mm/r)

|

Depth of Cut ap(mm)

|

|

1.1

|

(Wheel face facing Roughing)

|

SBN850 CNGN120412 S02020

|

F27R-CCSN-D50*150-CN1204

|

400-500

|

0.3~0.5

|

1.5~2

|

|

2.1

|

(Internal roughing

|

SBN850 CNGN120412 S02020

|

S40-260-CCLNL1204

|

400~750

|

0.3~0.5

|

1.5~2

|

|

3.1

|

(Pad face roughing)

|

SBN850 CNGN120412 S02020

|

CCLNL2525M1204

|

400-500

|

0.3~0.5

|

1.5~2

|

|

3.2

|

(Wheel external roughing)

|

SBN850 CNGN120412 S02020

|

CCLNL2525M1204

|

400~750

|

0.3~0.5

|

1.5~2

|

|

4.1

|

(Groove roughing)

|

SBN850 RCMX060500 S02020

|

CRDCN2525M0605

|

550~700

|

0.1~0.3

|

0.2~0.5

|

|

Processing No.

|

Processing Part

|

CBN Inserts Models and Grade

|

Suitable Tool Holder

|

Cutting Speed Vc

(m/min)

|

Feed Rate Fr(mm/r)

|

Depth of Cut ap(mm)

|

|

1.1

|

(Wheel face facing Roughing)

|

SBN850 CNGN120412 S02020

|

F27R-CCSN-D50*150-CN1204

|

400-500

|

0.3~0.5

|

1.5~2

|

|

2.1

|

(Internal roughing

|

SBN850 CNGN120412 S02020

|

S40-260-CCLNL1204

|

400~750

|

0.3~0.5

|

1.5~2

|

|

3.1

|

(Pad face roughing)

|

SBN850 CNGN120412 S02020

|

CCLNL2525M1204

|

400-500

|

0.3~0.5

|

1.5~2

|

|

3.2

|

(Wheel external roughing)

|

SBN850 CNGN120412 S02020

|

CCLNL2525M1204

|

400~750

|

0.3~0.5

|

1.5~2

|

|

4.1

|

(Groove roughing)

|

SBN850 RCMX060500 S02020

|

CRDCN2525M0605

|

550~700

|

0.1~0.3

|

0.2~0.5

|

|

Processing No.

|

Processing Part

|

CBN Inserts Models and Grade

|

Suitable Tool Holder

|

Cutting Speed Vc

(m/min)

|

Feed Rate Fr(mm/r)

|

Depth of Cut ap(mm)

|

|

1.1

|

(wheel face finishing)

|

SBN850 CNGN120412 S02020

|

F27L-D50*150-CCLN1207-1

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

2.1

|

(wheel external finishig)

|

SBN850 CNGN120412 S02020

|

F27L-D50*150-CCLN1207-1

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

2.2

|

(external finishing)

|

SBN850 CNGN120412 S02020

|

F27L-D50*150-CCLN1207-1

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

3.1

|

(Groove finishing)

|

SBN850 RCMX060500 S02020

|

CRDCN2525M0605

|

550-700

|

0.1~0.2

|

0.2~0.5

|

|

4.1

|

(pad face semi-finishing)

|

SBN850 SCGN090408W

|

CSLCR2020K0904

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

Processing No.

|

Processing Part

|

CBN Inserts Models and Grade

|

Suitable Tool Holder

|

Cutting Speed Vc

(m/min)

|

Feed Rate Fr(mm/r)

|

Depth of Cut ap(mm)

|

|

1.1

|

(pad face finishing)

|

SBN850 SCGN090408W

|

CSLCR2020K0904

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

2.1

|

(starting point finishing))

|

SBN850 CNGN120412 S02020

|

F27L-D50*150-CCLN1204

|

650~750

|

0.2~0.3

|

0.2~0.5

|

|

3.1

|

(internal finishing)

|

SBN850 CNGN120412 S02020

|

F27L-D50*150-CCLN1204

|

650~750

|

0.2~0.3

|

0.2~0.5

|

1) The Solid CBN Insert is more suitable for high-speed, high-feed, and deep-cut processing.

2) The Solid CBN Insert is processed in one rough and fine process, with less processing steps, less tool change times, shortened processing time, and greatly improved processing efficiency.

Product Categories

Hot Searches