- Product Details

- {{item.text}}

Quick Details

-

Function:

-

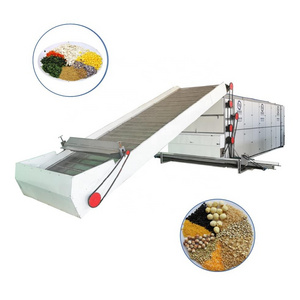

Buckwheat Chickpeas corn peanut soybean rice wheat drying

-

name:

-

Continuous flow grain dryer

-

item:

-

diesel burner grain dryer

-

suit for:

-

grain drying

-

Application:

-

Corn,rice paddy,wheat,Sorghum

-

product name:

-

Rice Drying Machine

-

type:

-

Seed dryer machine

-

raw material:

-

Buckwheat Chickpeas corn peanut soybean rice wheat

-

feature:

-

corn Grain Dryer

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Quick Details

-

Core Components:

-

other

-

Place of Origin:

-

Henan, China

-

Usage:

-

rice paddy dryer machine

-

Function:

-

Buckwheat Chickpeas corn peanut soybean rice wheat drying

-

name:

-

Continuous flow grain dryer

-

item:

-

diesel burner grain dryer

-

suit for:

-

grain drying

-

Application:

-

Corn,rice paddy,wheat,Sorghum

-

product name:

-

Rice Drying Machine

-

type:

-

Seed dryer machine

-

raw material:

-

Buckwheat Chickpeas corn peanut soybean rice wheat

-

feature:

-

corn Grain Dryer

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

None

Product Description

Advantage of continuous flow grain dryer /diesel burner grain dryer

1.Short drying time(2-3h per batch), keep cereal with natural feature,reduce drying cost and save labor and time.

2.Body compact, easy operation, especially design for small and middle farmer and company

3.High drying efficiency, easy transport, save space, it can be moved to farm and drying everywhere.

4.Widely use for corn, paddy, wheat, sesame, etc.

Features of continuous flow grain dryer /diesel burner grain dryer

1.Equiped with wheel, can be towed by tractor.

2.Cereal without pollution, fresh air as input and make sure cereal clean without pollution.

3.Automatic control system for temperature and misture

4.Machine can be separate and install together, easy transport

Details Images

Specification

|

Continuous flow grain dryer /diesel burner grain dryer Specifications

|

|

|

|

|

|

|||||

|

Model

|

|

FY-LHG1

|

FY-LHG2

|

FY-LHG3

|

FY-LHG6

|

|||||

|

Silo Volume

|

|

1.5m³

|

3.8m³

|

6.5m³

|

9.6m³

|

|||||

|

Dry type

|

|

Low temperature hot air cycle dry

|

|

|

|

|||||

|

Air temperature range

|

|

Paddy:45-60℃;Corn:100-130℃;Wheat:90-110℃

|

|

|

|

|||||

|

Transport height

|

|

2.1m

|

2.7m

|

2.9m

|

2.9m

|

|||||

|

Operation height

|

|

2.1m

|

3.46m

|

3.85m

|

4.92m

|

|||||

|

Area

|

|

8m2

|

13m2

|

15.5m2

|

16.3m2

|

|||||

|

Coal and wood Oven

|

|

Clean oven,Ignition by manual

(If use other fuel,need different design) |

|

|

|

|||||

|

Fuel consumption

|

Coal

|

(Standard conditions)18kg/t

|

|

|

|

|||||

|

|

Gas

|

(Standard conditions)7m³/t

|

|

|

|

|||||

|

|

Diesel oil

|

(Standard conditions)7.5L/t

|

|

|

|

|||||

|

Total power

|

|

3kw

|

8.5kw

|

13.13kw

|

19.4kw

|

|||||

|

Capacity:

|

|

1T/batch

|

2T/batchh

|

4T/batch

|

6T/batch

|

|||||

|

|

|

Note:Each batch need 2-3h

|

|

|

|

|||||

|

Precipitation rate (%/h)

|

|

Paddy:1.7-2.5% ;Corn:3.8-6% ;Wheat:2.8-4.5%

|

|

|

|

|||||

|

Safety Devices

|

|

Thermal relay,Error alarm, Times Switch, Overheat alam

|

|

|

|

|||||

|

Daily production is calculated by the condition from25% to 14% moisture.

|

|

|

|

|

|

|||||

Hot Searches