- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

t103

-

Name:

-

date stamp insert

-

Hardness::

-

45-52 HRC

-

Material:

-

SUS420

-

Price:

-

factory price

-

Size:

-

6, 8, 10 , 12 , 14

-

Shaping mode:

-

plastic injection mold

-

type1:

-

recycle inserts

-

type2:

-

month stamp,year stamp,blank stamp

-

product:

-

Vehicle/Medical Equipment/automobile industry mold

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

tianying

-

Model Number:

-

t103

-

Name:

-

date stamp insert

-

Hardness::

-

45-52 HRC

-

Material:

-

SUS420

-

Price:

-

factory price

-

Size:

-

6, 8, 10 , 12 , 14

-

Shaping mode:

-

plastic injection mold

-

type1:

-

recycle inserts

-

type2:

-

month stamp,year stamp,blank stamp

-

product:

-

Vehicle/Medical Equipment/automobile industry mold

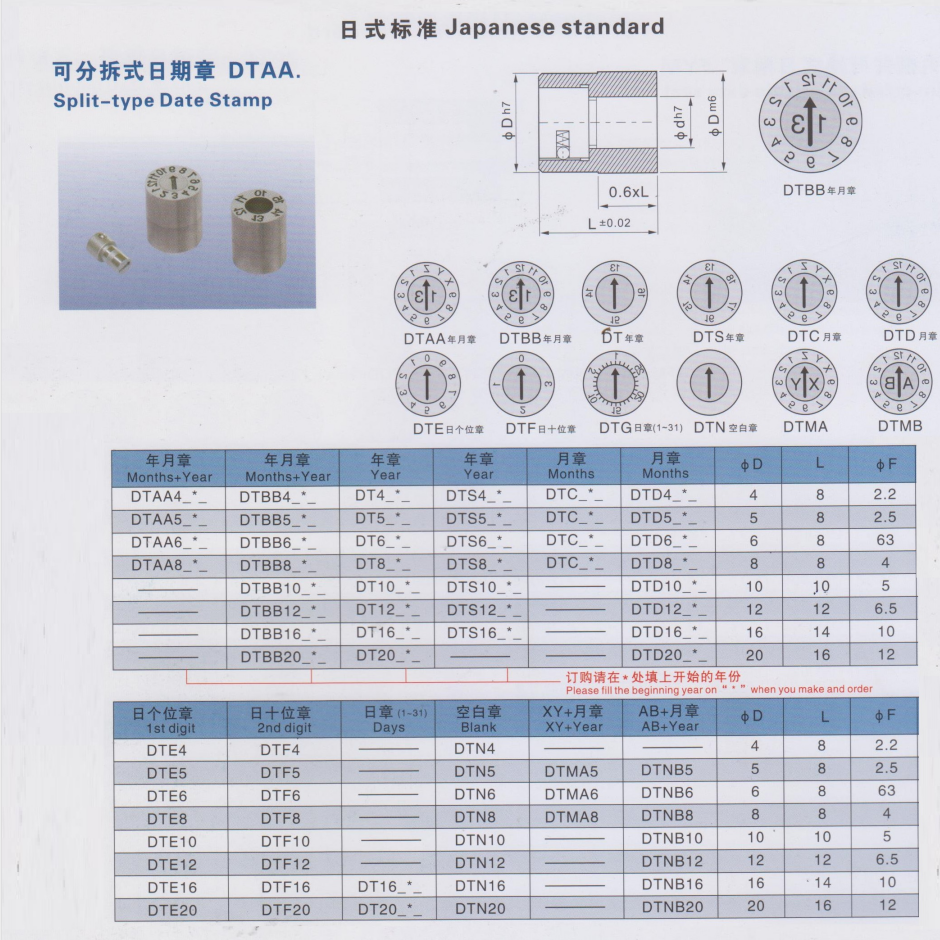

mold part Date stamp code heat stamp date inserts for dies

:

Date Stamp mold day stamp 1-12

Mold Date Stamp

, also known as the date code, mainly used in plastic mold, set in the cavity or core surface or side wall, with its associated graphics or digital surface, the letter information Injection molding is on the product, to identify the production date, materials, customer number, production schedules, etc., in order to better traceability and differentiate products, improve production efficiency and management.

Advantage:

1:From the subtype surface of mould, you can quickly replace the inserted parts without dismantling mould.

2:Ball Positioning

3:The inserted parts cna change its year,suitable for long-term production mould,so as to save cost of the mould.

Date stamp install method:

Use copper or other soft material to knock when install it.

Make sure the diameter and the depth of the hole is right.

The center hole can not exceed the range of the lid,to avoid sinking when ejecting.

Notice the characters direction,to make sure the plastic proolucts beauteous.

Can per the bevel to process when find R face or bevel when inatall it.

For more information about our products, please visit our website:

www.tianyingdg.com

Dongguan Tianying Mould fitting Co., LTD . entered into the market of mould cooling components as a factory since 2005.

Now we offer a comprehensive range of products about standard and customized mold components, mainly for cooling circuits for injection moulds and diecasting dies in the most effective way. The cooling system components are products according to standard,

compatible with DME, HASCO, STAUBLI, MISUMI, JIS, PROGRESSIVE, STRACK, SUPERIOR standard etc, we take some products as samples list below:

1.pipe plugs ,

2.Spiral plug baffles, ,Straight plug baffles,

3.Threadless pressure plugs ,

4.Jiffy Connectors,

5.Heat pipe,

6.Spiral Cooling Tube,

7.Cooling circuit plugs

8. date marked pins

9. air poppet

10.slide retainers

11. nipple

12. mold coupling

13. latch lock

We can also produce customized products to meet our customer's special requirement.

Competitive Advantages:

1).OEM available

2)Top Quality ,nice prices\

3) Experienced workers

4).More materials available , like Brass , Steel , aluminum , etc .

5).Quick goods delivery : 5 to 10 days .

6) Professional Technology Support.

7) Quality Tracing System

8).Customers quick response System

9).Efficient Team Work .

DME , HASCO ,MISUMI ECT Quick coupling and nipple plug

Plastic injection mould parts

Dongguan Tianying Mould fitting Co., LTD. was located in the town of mould, CHANGAN TOWN, and has been producing mould cooling components for over 10 years.

During this 10 years' effort, our business is not just limeted to research & development, production, we also do wholesale and retail.

Clients vary from regions to regions and we have kept an eye to overseas countries since 2009 as well.

We have stable quality, seldom complains from clients, and full production capacity.

We have ability of research & development, and delivery is made promptly.

Want samples? Please press the button Send below, let us know what you want.