- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

1200

-

Dimension(L*W*H):

-

1241X2145X2310MM

-

Product name:

-

Muller Mixer Picture

-

Usage:

-

mixing green sand

-

Foundry Machine:

-

China Green Sand Making

-

Capacity:

-

5-50 T/h

-

Feature:

-

High Efficency

-

Final products:

-

Foundry sand

-

Advantage:

-

Low Cost

-

Casting plant:

-

Green Sand Casting Line

-

Technology:

-

Green Sand Casting Technology

-

Type:

-

High Efficiency

-

Weight:

-

5000KGS

-

Certification:

-

ISO9001 CE

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

Foundry Sand Mix Muller / Muller Mixer Picture

-

Brand Name:

-

Huaxin

-

Voltage:

-

380V

-

Power:

-

1200

-

Dimension(L*W*H):

-

1241X2145X2310MM

-

Product name:

-

Muller Mixer Picture

-

Usage:

-

mixing green sand

-

Foundry Machine:

-

China Green Sand Making

-

Capacity:

-

5-50 T/h

-

Feature:

-

High Efficency

-

Final products:

-

Foundry sand

-

Advantage:

-

Low Cost

-

Casting plant:

-

Green Sand Casting Line

-

Technology:

-

Green Sand Casting Technology

-

Type:

-

High Efficiency

-

Weight:

-

5000KGS

-

Certification:

-

ISO9001 CE

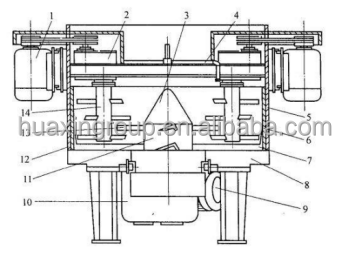

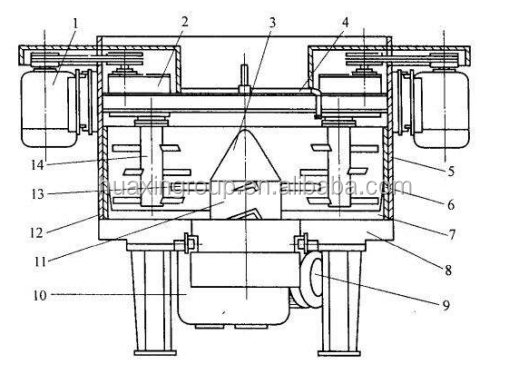

Foundry Sand Mix Muller For Foundry Company-Muller Mixer Picture

we recommend continuous type green sand mixer to you , if you are foundry plant or if you have sand reparation , please check this machine :

1. S11 series Roller Type Foundry Green Sand Mixer

Foundry Sand Mixer s mainly used for large and medium-sized foundry sand mixed system, mold can be mixed dry sand, since the hard sand, sand and core sand surface can also be used for glass, ceramics , refractories and other industries a variety of mixed powder granular materials.

Technical parameters

|

Item |

S1110 |

S111A |

S114C |

S1118 |

S1120D |

S1122 |

|

Diameter(mm) |

Φ1000 |

Φ1220 |

Φ1820 |

Φ1800 |

Φ2000 |

Φ2240 |

|

Feeding amount of one line(kg) |

110 |

140 |

500 |

500-650 |

900 |

1350 |

|

Productivity(t/h) |

1.5~2.5 |

2.8~4 |

10~13 |

13~15 |

20 |

30 |

|

Speed of main spindle(r/min) |

44 |

34.7 |

34 |

36 |

34 |

31 |

|

Power of main motor(kw) |

4 |

5.5 |

15 |

22 |

37 |

55 |

2. S14 series Rotor type sand mixer

S14 series rotor sand mixer works with the low-speed rotor mixer scraper combinating with the medium-speed rotor. large mixing quantity, good quality and high efficiency.

This rotor sand mill series equipments can mix single type sand for molding machines, and also can use for mixing dry sand, self-hardening sand, facing sand and core sand. Besides, it also can prepare all kinds ofmixed powder loaded materials for glass, ceramics, refractories,etc.

Foundry Sand Mixer is equipped with low-speed scraper with the best combination of rotor speed, sand volume, mixing ability, good overall performance sand.

Foundry Sand Mixer is equipped with diabase cast stone, tungsten carbide surfacing, fillers and other new materials, greatly improving the life of wearing parts

Foundry Sand Mixer is equipped with latest rotary discharge door open and flexible, reliable and completely solved the problem of sand at the bottom drain.

Foundry Sand Mixer is equipped with symmetric access door opened very convenient for maintenance and cleaning.

Foundry Sand Mixer is used very easy and install steel base.

|

Model |

Disc diameter(mm) |

Feeding Capacity(kg/s) |

Productivity(t/h) |

Power(kw) |

|

S1408 |

800 |

150 |

4 |

7.5 |

|

S1410A |

1000 |

200 |

5 |

8.3 |

|

S1412 |

1200 |

330 |

8 |

15.5 |

|

S1415A |

1600 |

660 |

16 |

20 |

|

S1418 |

1800 |

800 |

18-20 |

31 |

|

S1420B |

2000 |

1200 |

25-30 |

37 |

|

S1422B |

2200 |

1500 |

40-48 |

45 |

|

S1425B |

2500 |

2000 |

66-90 |

135 |

3.S13 series roller and rotor type sand mixer

The working mechanism of this series of sand mixers consists of rolling wheel, sand mixing rotor and scraper. The rolling force and grinding action of the rolling wheel are retained, so that the molding sand has higher strength, and at the same time, the strong stirring action of the sand mixing rotor is increased, so that the molding sand strength rises rapidly, the sand mixing period is short, the productivity is high, and the sand quality is loose and the air permeability is good.

Technical parameter:

|

1 |

Each mixing capacity |

200kg |

|

2 |

Each mixing time |

3-8min |

|

3 |

Productivity |

1500-2500kg/h |

|

4 |

Disk diameter |

φ1200m |

|

5 |

speed of mainshaft |

44.8r/min |

|

6 |

Total transmission ratio |

57 |

|

7 |

Motor power |

7.5KW |

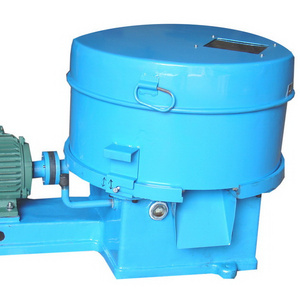

3. Bowl type sand mixer for resin sand

S20 series spherical/bowl-shaped sand mixer is a new type of high-efficiency sand mixer. It is mainly mixed furan resin sand for cold core box core shooting machine.

|

|

S202 |

S204 |

S206 |

S208 |

S210 |

|

Productivity(t/h) |

1.5~2.5 |

2.5~3.5 |

4.5~5.5 |

6.5-7.5 |

8.5-9.5 |

|

Each mixing capacity (kg) |

15~30 |

35~50 |

40~100 |

150 |

200 |

|

cycle period(s) |

35~40 |

35~40 |

35~40 |

35-40 |

35-40 |

|

Each mixing time(s) |

15~20 |

15~20 |

15~20 |

30-60 |

30-60 |

|

Sphere inner diameter(mm) |

500 |

600 |

800 |

1000 |

1200 |

|

speed(r/min) |

270 |

270 |

270 |

130 |

130 |

|

power(kw) |

4 |

5.5 |

11 |

15 |

18.5 |

T he working mechanism consists of two sand mixing blades symmetrically installed on the crosshead. When mixing sand, the transmission device drives the main shaft to rotate at high speed, and drives the two blades with special spiral angles to rotate, turning up the sand in vortex motion, and fixing the blades on the upper hemisphere to reflect the sand again. In this way, the sand, curing agent and resin sand binder are mixed quickly by repeated circulation, and molding sand is discharged from the sand outlet located below the sphere.

On the one hand, the adoption of spherical basin can reduce the dead angle of sand stacking and accelerate the circulation of sand flow; on the other hand, under the action of spiral blades, the inertia of sand makes the sand flow upward along the spherical surface, then rolls down under the action of gravity, and then is thrown up by the latter blade. The main shaft of the sand mixer has high rotating speed, and the blades have strong throwing and spreading effects on materials, convection friction and rolling, so the sand mixing efficiency is high.

Resin sand mixer machine for cold core ( double arm sand mixer )

,

there are so many kinds of sand casting equipments at our factory , we don this line over 20years in China

contact us