- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NEWGOER

-

Model Number:

-

TGA-101, TGA

-

Temperature range:

-

RT ~ 1150℃

-

Temperature resolution:

-

0.01℃

-

Temperature fluctuation:

-

±0.01℃

-

Heating rate:

-

0.1~100℃/min

-

Temperature control:

-

Heating, Constant temp

-

Balance sensitivity:

-

0.01mg

-

Product name:

-

TGA Thermo Gravimetric Analyzer

-

Function:

-

determine a material's thermal stability and its fraction

-

Power Supply:

-

AC220V 50Hz

Quick Details

-

Warranty:

-

18 Months

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NEWGOER

-

Model Number:

-

TGA-101, TGA

-

Temperature range:

-

RT ~ 1150℃

-

Temperature resolution:

-

0.01℃

-

Temperature fluctuation:

-

±0.01℃

-

Heating rate:

-

0.1~100℃/min

-

Temperature control:

-

Heating, Constant temp

-

Balance sensitivity:

-

0.01mg

-

Product name:

-

TGA Thermo Gravimetric Analyzer

-

Function:

-

determine a material's thermal stability and its fraction

-

Power Supply:

-

AC220V 50Hz

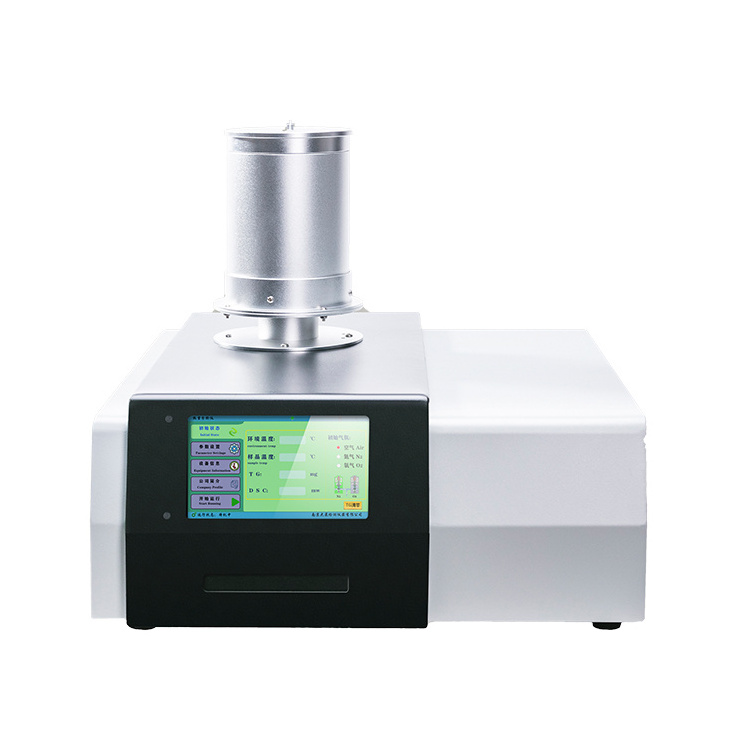

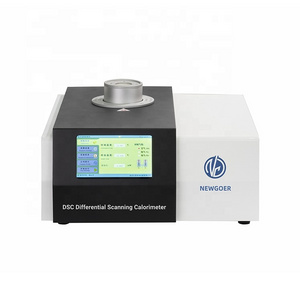

TGA Plastic Thermo Gravimetric Analysis

Differential Thermal Analyzer Differential Thermal Analyzer Price

Summary :

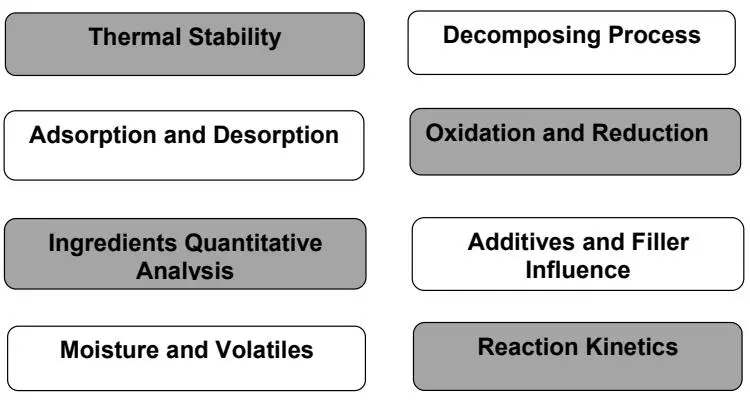

Thermal weight analysis method (TG, TGA) is to observe the quality of the sample with temperature or time during heating, constant temperature, or cooling, and the purpose is to study the thermal stability and components of the material.It is widely used in plastic, rubber, coatings, drugs, catalysts, inorganic materials, process optimization and quality monitoring.

The main characteristic of thermal weight analysis is strong quantitative, can accurately measure the mass change and rate of change.According to this characteristic, it can be said that as long as the material mass changes when thermal, can be studied by thermal weight analysis.Thermal weight analysis.

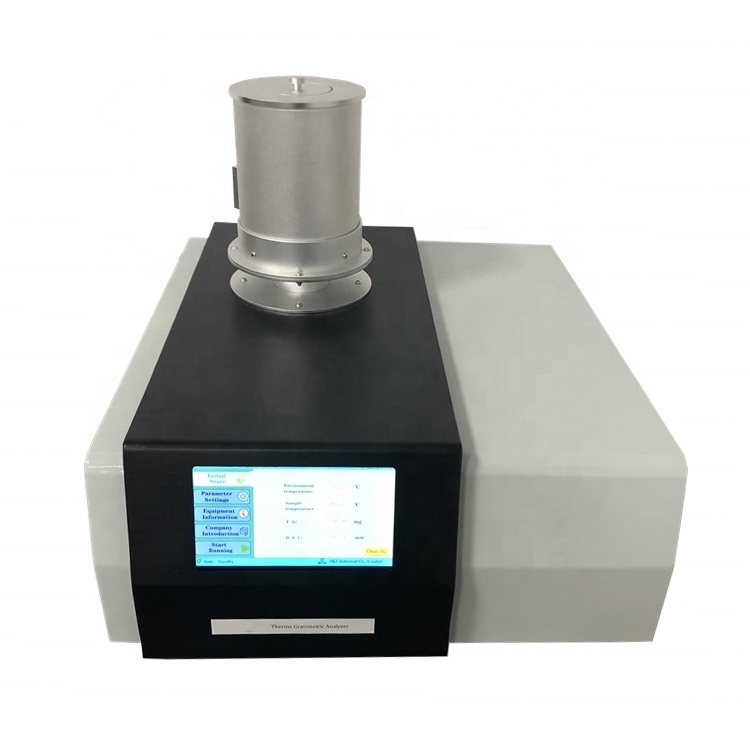

Use the top mounting sample structure.Compared with other structures, the top loading structure is characterized by the ease of operation.The atmosphere flows from down up, so only a small flow is needed to take away the decomposition product.

Speficiations of TGA:

|

Model |

TGA-101 |

TGA-103 |

TGA-105 |

|

Temperature range |

RT ~ 1150℃ |

RT ~ 1350℃ |

RT ~ 1550℃ |

|

Temperature resolution |

0.01℃ |

||

|

Temperature fluctuation |

±0.01℃ |

||

|

Heating rate |

0.1~100℃/min |

||

|

Temperature control |

Heating, Constant temp |

||

|

Cooling time |

15min (1000…100℃) |

||

|

Range of balance |

1mg~3g |

||

|

Balance sensitivity |

0.01mg |

||

|

Holding time |

0 ~ 300min free |

||

|

Test conditions |

Inertia, Oxidation, Reduction, Static and dynamic |

||

|

Conditions device |

Built-in gas flow meter |

||

|

Atmosphere control |

Automatic |

||

|

Software |

Auto Record TG curve.

Software with multi-point correction function, high and low temperature test more accurate. |

||

|

Communication Interface |

Standard USB, Professional software |

||

|

Power Supply |

AC220V 50Hz |

||

Features:

-

1. Furnace body heating adopts customized nickel chrome wire double row winding system, reduce

interference, more high temperature resistance.2. Tray sensor, made of alloy wire seiko, with high temperature resistance, oxidation resistance, corrosion resistance and other advantages.

3. Power supply, the circulation cooling part is separated from the main engine to reduce the

influence of heat and vibration on the microthermal balance.4. The upper open cover structure is convenient to operate. It is very difficult to put samples in the

upper moving furnace body, and it is easy to damage the sample bar.5. The host machine adopts isolated heating furnace body to the thermal impact of the chassis and

micro thermal balance.6. Furnace body can be replaced according to customer requirements.