- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

10" x 10" x 12"

-

Weight (T):

-

0.2 T

-

Power (kW):

-

4

-

Applicable Industries:

-

industrial

-

Temperature control:

-

51segments Programmable

-

Heating element:

-

Resistance Wire

-

Heating Rate:

-

10 ℃ /min

-

Thermocouple:

-

B type

-

Max temperature:

-

1100℃

-

Power(KW):

-

5

-

Power(W):

-

Adjustable

-

Weight:

-

100KG

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

Temperature Control System

-

Brand Name:

-

SYN

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

10" x 10" x 12"

-

Weight (T):

-

0.2 T

-

Power (kW):

-

4

-

Applicable Industries:

-

industrial

-

Temperature control:

-

51segments Programmable

-

Heating element:

-

Resistance Wire

-

Heating Rate:

-

10 ℃ /min

-

Thermocouple:

-

B type

-

Max temperature:

-

1100℃

-

Power(KW):

-

5

-

Power(W):

-

Adjustable

-

Weight:

-

100KG

-

Certification:

-

CE

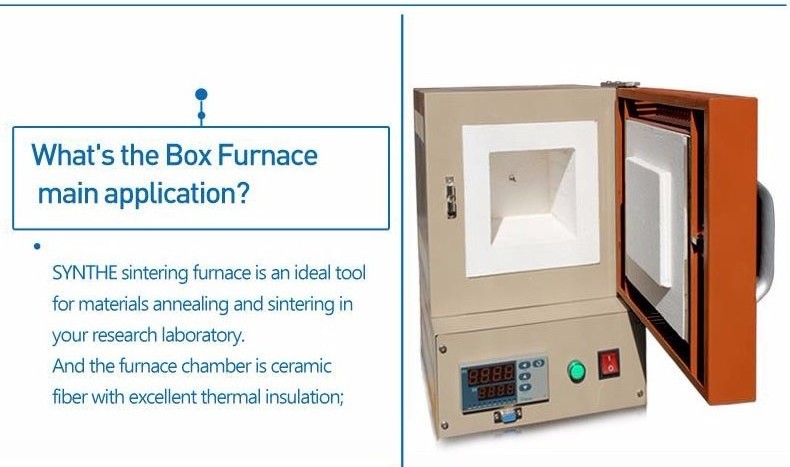

Factory Price Small Industrial Electric High Temperature Metal Melting Muffle Furnace

1.Double layer steel casing with air cooling to keep furnace surface temperature lower than 60°C, much safer to touch.

2.High purity fibrous alumina insulation for Max. energy saving.

3.Special refractory coating on inner and heating element to increase furnace life.

4.PID temperature controller to meet full automatic constant temperature function.

5.Fast heat-up to reduce energy consumption.

6.Over temperature protection and over-load protection.

|

Specification

|

|

|

|

Furnace Structure

|

Double shell steel case with cooling fan to keep outside case cool

High purity alumina fiber insulation for max. energy saving |

|

|

Material

|

Energy saving 1800 grade fibrous alumina insulation

High purity Al 2 O 3 coating. |

|

|

Standard Working Temperature

|

1000°C (continuous)

|

|

|

Maximum Working Temperature

|

1100°C (Peak at < 60 minutes)

|

|

|

Temperature Control

|

Digital temperature control with 51 segments programmable and automatic PID function and overheated alarm.

|

|

|

Heating Rate

|

0-10 °C/min

|

|

|

Temperature Accuracy

|

+/- 1 °C

|

|

|

Chamber Dimension

|

10" x 10" x 12" (250x 250x 300 mm )

|

|

|

Heating Element

|

Resistance Wire

|

|

|

Working Voltage

|

208~240V AC, Single phase, 50/60Hz

|

|

|

Power

|

5 kw

|

|

|

Thermocouple

|

B type

|

|

|

Gas inlet/outlet (optional)

|

Optional 1/4" barbed gas inlet/outlet can be installed on back panel of furnace upon customer request.

|

|

|

Warranty

|

One year manufacture limited warranty and free replace all defective parts (not including spare parts).

|

|

We also offer furnace spare parts, such as complete SiC and MoSi2 heating elements, Alumina crucibles. Many of our products have been developed for specific purposes with unique designs. We offer extensive research and development. Our highly qualified staff of engineers, scientists, technicians, and plant personnel, will work with you to produce a cost effective, superior product to meet your refractory needs. Synthe takes pride in our commitment to operational excellence. We have the drive, knowledge and ability to meet our customer’s specific and demanding needs for their everyday usage. We will work with you to get things done!

1. One year quality warranty for whole furnace.

2. Reply your inquiry in 24 working hours.

3. Experienced staffs answer all your questions in fluent English.

4. Customized design is available.

5. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

App control system

Specializing in research and development lab furnace for more than 10 years gives you the most professional service.

Responsible production lead to high quality.

Large-scale production lines ensure the fast delivery time.

The best package keeps your goods safer and transport easier.

A:We have our own factory and excellent technical team,and we are accept OEM service.

2. We are not professional for operation and installation of your machine?

A:While it is not a stumbling block,our machine is asy to operate,no need to professional training,and the instruction manual and video sent to you are enough.What’smore,we have professional engineers and they can solve all questions.

3. Which shipment is available?

A:By sea,by air,by express or as your requirement.

4. Do you inspect the finished products?

A:Yes,each step of production and finished products will be carried out inspection by QC department before shipping.