- Product Details

- {{item.text}}

Quick Details

-

Material quality:

-

SS304

-

Production capacity:

-

100-2000kg/h

-

certification:

-

CE ISO9000 SGS

-

Energy:

-

electricity, oil diesel, gas, steam

-

Motor brand:

-

Siemens, ABB or Chinese brand

-

Shapes:

-

Various upon clients' demands.

-

Power:

-

22kw,30kw,45kw,55kw,75kw,90kw,120kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Weight:

-

1500 kg

-

Whatsapp:

-

+8618396800226

-

Material quality:

-

SS304

-

Production capacity:

-

100-2000kg/h

-

certification:

-

CE ISO9000 SGS

-

Energy:

-

electricity, oil diesel, gas, steam

-

Motor brand:

-

Siemens, ABB or Chinese brand

-

Shapes:

-

Various upon clients' demands.

-

Power:

-

22kw,30kw,45kw,55kw,75kw,90kw,120kw

animal floating fish feed pellet making extruder machine fish feed manufacturing machine suppliers

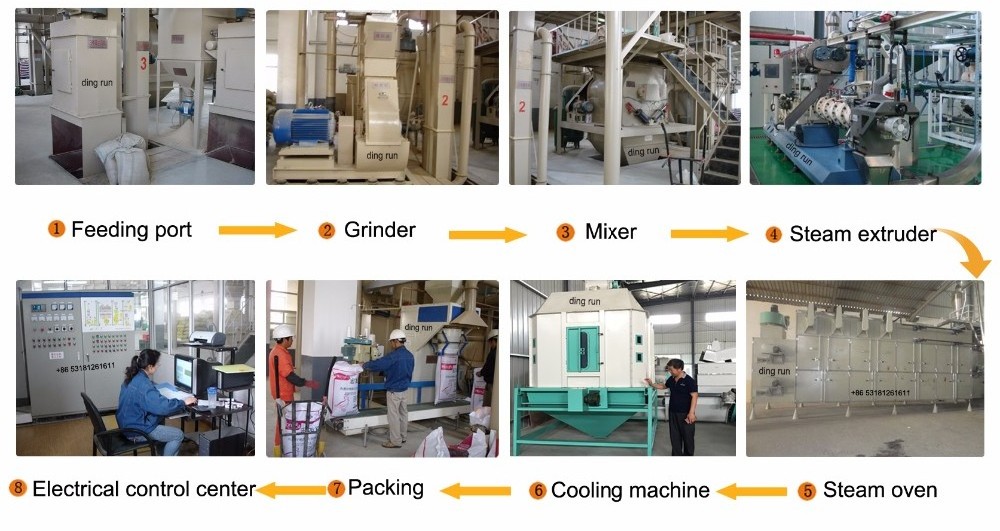

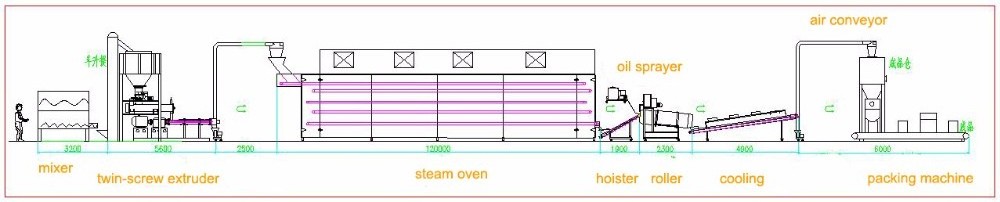

Flow chart :

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Machine parameters:

|

Model

|

Installed Power

(kw)

|

Power Consumption

(kw)

|

Capacity

(kg/h)

|

Dimension

(m)

|

|

65 processing line

|

74

|

52

|

120-180

|

17*1.2*2.2

|

|

70 processing line

|

95

|

70

|

200-300

|

20*1.5*2.2

|

|

75 processing line

|

110

|

82

|

250-400

|

26*1.5*2.2

|

|

85 processing line

|

139

|

104

|

400-800

|

28*3.5*4.3

|

|

90 processing line

|

132

|

75

|

800-1200

|

28*3.5*4.3

|

|

95 processing line

|

165

|

90

|

1500-2000

|

35*3.5*4.3

|

|

120 processing line

|

469

|

380

|

2000-2500

|

45*20*22

|

|

135 processing line

|

712

|

570

|

3000-3500

|

50*20*25

|

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Sample of fish feed pellet:

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

|

Name

|

grinder

|

|

Usage

|

corn, sorghum, wheats, beans, cottonseed meal,canola,etc.It can do coarse grinding and fine grinding processes

|

|

Type

|

Hammer Mill

|

|

Motor

|

7.5kw, 15kw, 22kw, 55kw, 75kw and so on

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Mixer

|

|

Usage

|

To mix the raw materials evenly, fast speed, no leakage.

|

|

Type

|

including Single axle and double shaft mixer

|

|

Motor

|

3kw, 4kw, 7.5kw etc.

|

|

Capacity

|

20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc.

|

|

Material

|

stainless steel, carbon steel

|

|

Name

|

Twin screw extruder(wet type/dry type)

|

|

Usage

|

To extrude the raw materials and make them to the required shape and size of the fish feed pellets by mould

|

|

model

|

DSE65, 70, 75, 90, 95, 120, 135

|

|

Motor

|

22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

Screw materials 38CrMoAl

stainless steel, carbon steel |

Dry type twin screw extruder for fish feed

Capacity ranges from 100 kg/h to 1 ton/h

Wet type twin screw extruder for fish feed

Capacity ranges from 200 kg/h to 10 ton/h

|

Name

|

Dryer (oven)

|

|

Usage

|

the expanded food go through the "s" passage, to be dried to increase the self life.

|

|

Type

|

electrical, steam, gas fired, diesel fired heating type

|

|

Motor

|

KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc.

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel, carbon steel

|

Electrical heating dryer

Gas or Diesel fired heating dryer

|

Name

|

Flavoring machine

|

|

Usage

|

To mix the oil and flavors on the surface of the fish feed

|

|

Type

|

single and double flavoring drum

|

|

Motor

|

0.75kw

|

|

Capacity

|

100kg/h to 10 ton/h

|

|

Material

|

stainless steel

|

|

Name

|

Packaging machine

|

|

Usage

|

To pack the fish feed with required weight

|

|

Flowing Process

|

Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor → Automatic bag sewing or heat sealing

|

|

Weight range

|

1-5kg/bag, 5-25kg/bag, 25-50kg/bag

|

|

Material

|

stainless steel, carbon steel

|

|

Type

|

Automatic

|

1.) Consultation service before, during,and after sales;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer.

1.Use anti-rust oil to wipe the equipment for animal Floating fish feed pellet making extruder machine

2.air cushion film packaging equipment for fish feed manufacturing machine

3.with a wooden box for the final step of packaging for fish feed manufacturing machine