- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Furnace

-

Voltage:

-

660/380V, 660/380V

-

Power:

-

800KW

-

Dimension(L*W*H):

-

2000x1000x2200, 2000x1000x2200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Name:

-

steel bar induction heating machine

-

Usage:

-

DIY induction heater

-

Type:

-

vertical or horizontal

-

rated temeprature:

-

1250 degree

-

MF frequency:

-

1-8khz or customized

-

Cooling:

-

closed cooling tower

-

Weight:

-

1.5T, 1.5T

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

hongteng

-

Machine Type:

-

Preheating furnace

-

Core Components:

-

Furnace

-

Voltage:

-

660/380V, 660/380V

-

Power:

-

800KW

-

Dimension(L*W*H):

-

2000x1000x2200, 2000x1000x2200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Name:

-

steel bar induction heating machine

-

Usage:

-

DIY induction heater

-

Type:

-

vertical or horizontal

-

rated temeprature:

-

1250 degree

-

MF frequency:

-

1-8khz or customized

-

Cooling:

-

closed cooling tower

-

Weight:

-

1.5T, 1.5T

-

Certification:

-

ISO

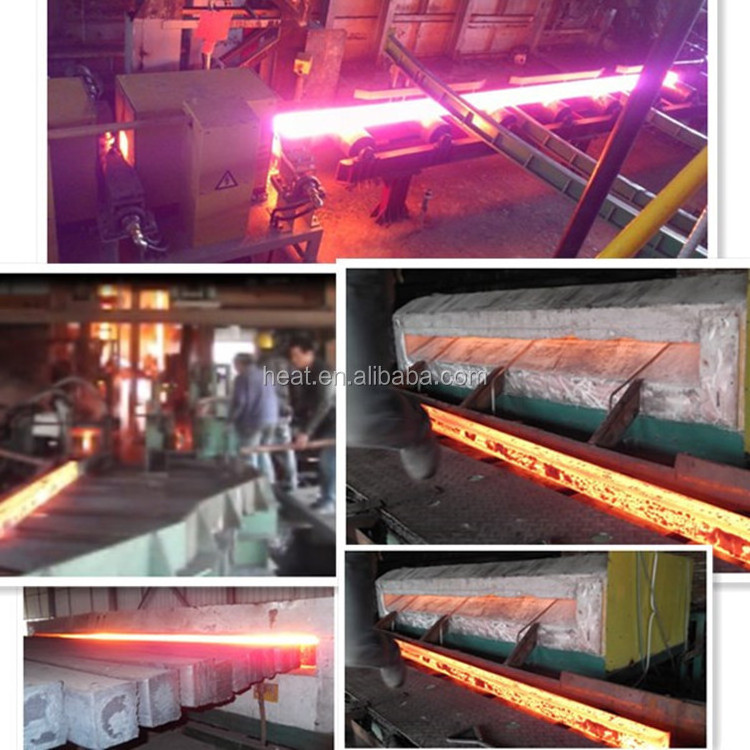

copper plating line small billet steel bar induction heater DIY heating machine

After full calculation and practical experience, the total weight of the billets need heated , is approximately 35% of the entire billet.

Main features of induction heating furnace

1. heating very fast

Since the induction furnace is heated by electromagnetic induction principle, its heat is generated by the workpiece itself. This heating method has the characteristics of high heating speed, very little oxidation, high heating efficiency, good process reproducibility, and extremely light discoloration of the metal surface.

2. With high degree of automation

Automatic unattended operation can be achieved and labor productivity can be improved.

3. Uniform heating, temperature control with high precision

Even heating ensures that the temperature difference between the core and the heated workpiece surface is small. Through the temperature control system, the temperature can be precisely controlled to ensure the accuracy of the product.

4. Easy to replace the induction furnace

Depending on the size of the workpiece being processed, different sizes of induction furnaces can be configured. Each furnace is designed with a hydraulic quick-connect device that makes furnace replacement faster, and easier.

5. Equipment protection completed

The whole machine is equipped with water temperature, water pressure, phase loss, over-voltage, over-current, pressure limiting/current limiting, startup over-current, constant current and buffer start-up, which makes the equipment start stable and reliable.

6. Low energy consumption, no pollution

Compared with other heating methods, the heating efficiency is high, which can effectively reduce energy consumption and does not pollute the environment.

Main technical paramters

| Technical parameters of induction heating furnace | ||||||

| Model | Working voltage (V) | Input current (A) | DC current(A) | Oscialltion frequency(KHZ) | Output power(KW) | Workpiece steel bar diameter (MM) |

| GTR-100 | 380 | 160 | 200 | 1-8KHZ | 100KW | 30-50MM |

| GTR-160 | 380 | 260 | 320 | 160KW | ||

| GTR-200 | 380 | 330 | 400 | 200KW | ||

| GTR-300 | 380 | 490 | 600 | 300KW | 40-70MM | |

| GTR-400 | 380 | 650 | 800 | 1-8KHZ | 400KW | |

| GTR-500 | 380 | 820 | 1000 | 0.4-8 | 500KW | |

| GTR-750 | 380 | 1200 | 1500 | 0.2-6 | 750KW | Over 70mm |

| GTR-1000 | 380 | 1650 | 2000 | 0.2-6 | 1000KW | |

| GTR-1500 | 380 | 2500 | 3000 | 0.2-1 | 1500KW | |

Steel billets induction heating furnace

Advantages of induction heating furnace

1. The sensor/coils heating fast, a uniform heating temperature, less oxidation loss, and a uniform metal composition.

2.It can be directly heated from the cold oven and it is convenient to change the variety.

3.Superb coil design, high quality thick-walled copper tubes, through the reasonable selection of the inter-turn distance of the induction coil makes the induction coil the highest conversion efficiency, the smallest resistance, more energy can be used for heating, high strength, the coil is not prone to arc and expansion Causes damage.

4. The firm coil support system makes each coil tightly locked and eliminates the possibility of an intermittent circuit.

Hot rolling line making rebar