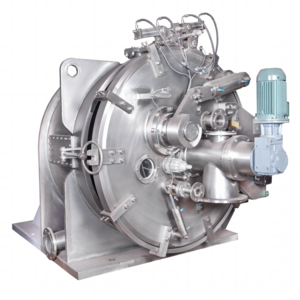

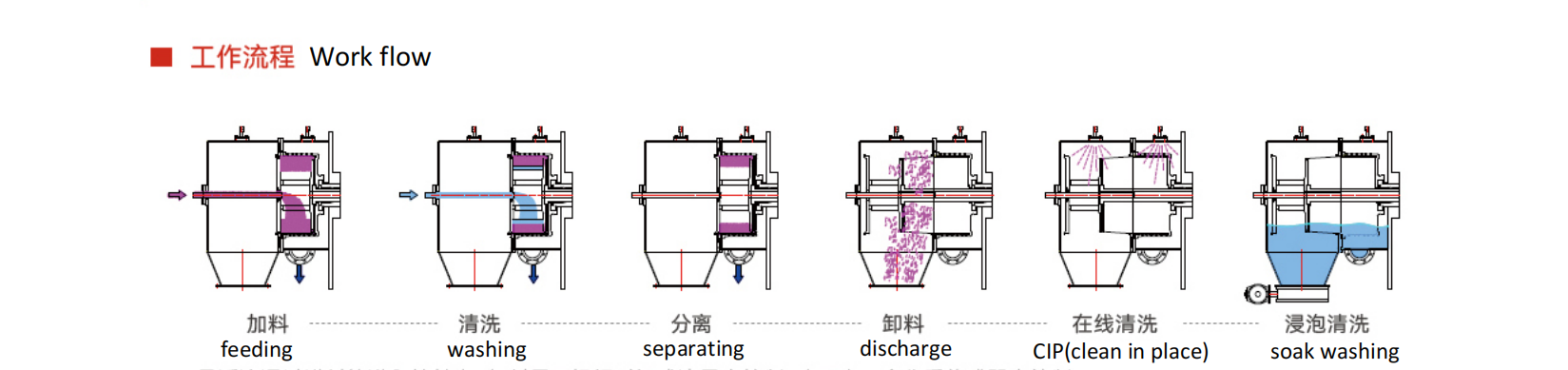

FW series horizontal inverting centrifuges with intermittent feeding and intermittent discharging. Feeding, separating, washing, dehydration and other operating procedures are completed in full speed; discharging is completed under the condition of deceleration, which avoids material to contact with subject other than equipment, and can also protect the operator and material from contamination.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220,380.460V...

-

Weight:

-

7000

-

Dimension(L*W*H):

-

4484*1940*2650mm

-

Application:

-

Food chemical industry

-

Rotating Speed:

-

1600rpm

-

Control system:

-

PLC control

-

Separation phase:

-

Two Phase Solid Liquid

-

Certification1:

-

ISO

-

Drum Diamete:

-

800mm

-

Certification2:

-

CE

-

After-sales Service Provided:

-

Online Support Field Maintenance

-

Machine type:

-

Filter centrifuge

-

MOC:

-

Stainless Steel316/321/304

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

Saideli

-

Voltage:

-

220,380.460V...

-

Weight:

-

7000

-

Dimension(L*W*H):

-

4484*1940*2650mm

-

Application:

-

Food chemical industry

-

Rotating Speed:

-

1600rpm

-

Control system:

-

PLC control

-

Separation phase:

-

Two Phase Solid Liquid

-

Certification1:

-

ISO

-

Drum Diamete:

-

800mm

-

Certification2:

-

CE

-

After-sales Service Provided:

-

Online Support Field Maintenance

-

Machine type:

-

Filter centrifuge

-

MOC:

-

Stainless Steel316/321/304

Product Description

FW Inverting Centrifuge

Main Feature

Main features

1. Fully airtight structure design, reliable sealing, no pollution to the material.

2. Automatic separation can be realized for materials that are difficult to dehydrate.

3. The shell can be fully turned over, equipped with CIP(clean in place) and immersion washing automatic control function.

4. No scraper mechanical parts when discharging, no damage to the grain.

5. The filter cloth has no material residue, which is convenient for the separation of the next batch of material.

6. It can be installed through the wall to separate the power area from the process area to meet clean production requirements

7. It is unmanned and fully automatic in control and operation.

8. Optional pressurized separation unit (PAC) is available to improve dehydration efficiency.

2. Automatic separation can be realized for materials that are difficult to dehydrate.

3. The shell can be fully turned over, equipped with CIP(clean in place) and immersion washing automatic control function.

4. No scraper mechanical parts when discharging, no damage to the grain.

5. The filter cloth has no material residue, which is convenient for the separation of the next batch of material.

6. It can be installed through the wall to separate the power area from the process area to meet clean production requirements

7. It is unmanned and fully automatic in control and operation.

8. Optional pressurized separation unit (PAC) is available to improve dehydration efficiency.

Specification

|

Item/Model

|

FW-300

|

FW-630

|

FW-800

|

FW-1000

|

FW-1300

|

|

Drum diameter (mm)

|

300

|

630

|

800

|

1000

|

1300

|

|

Drum volume (L)

|

6.5

|

70

|

120

|

200

|

350

|

|

Filter area (m2)

|

0.14

|

0.56

|

0.85

|

1.26

|

2.0

|

|

Max. revolving Speed (r/min)

|

3000

|

1800

|

1600

|

1270

|

1000

|

|

Max. Separating factor (N)

|

1500

|

1141

|

1145

|

901

|

726

|

|

Weight of Machine (Kg)

|

1500

|

4000

|

7000

|

10000

|

14000

|

|

Outline Size (mm) (L×W×H)

|

2267×1108×1480

|

3640×1710×2330

|

4484×1940×2650

|

5140×2260×2900

|

5900×2050×3250

|

Working principle

Working principle

This machine mainly consists of rotation mechanism, discharging mechanism, machine base, bearing combination, drum, pushing disk, screen, shell, electric control part and so on.

Drum runs in the high-speed, the suspension enters the drum through the feed pipe. Under the action of centrifugal force, the suspension is evenly distributed on the filter cloth of drum, the liquid phase is discharged out of the machine from the mother liquid pipe through the pores of the filter cloth, screen mesh gaps and the drum filter holes, and the solid phase is trapped in the screen to form a ring-shaped filter residue layer. When discharging, the main machine first reduces the speed to the discharging speed, starts the discharging motor and pushes out the push plate from the drum. The two ends of the filter cloth are fixed on the push plate and the drum, so, at this time the filter cloth inside and outside is inverted, and the retained material is turned over to the outside of the filter cloth. Meanwhile, under the action of centrifugal force field, the material is thrown away from the filter cloth and discharged from the discharge hopper.

Drum runs in the high-speed, the suspension enters the drum through the feed pipe. Under the action of centrifugal force, the suspension is evenly distributed on the filter cloth of drum, the liquid phase is discharged out of the machine from the mother liquid pipe through the pores of the filter cloth, screen mesh gaps and the drum filter holes, and the solid phase is trapped in the screen to form a ring-shaped filter residue layer. When discharging, the main machine first reduces the speed to the discharging speed, starts the discharging motor and pushes out the push plate from the drum. The two ends of the filter cloth are fixed on the push plate and the drum, so, at this time the filter cloth inside and outside is inverted, and the retained material is turned over to the outside of the filter cloth. Meanwhile, under the action of centrifugal force field, the material is thrown away from the filter cloth and discharged from the discharge hopper.

Machining center

Quality test

Customer Site Photos

FAQ

1. who are we?

We are based in Jiangsu, China, start from 1992,sell to Domestic Market(78.00%),North America(5.00%), Southeast Asia(3.00%), South Asia(2.00%), South America(2.00%), Eastern Asia(2.00%), Oceania(1.00%), Africa(1.00%), Southern Europe(1.00%), Northern Europe(1.00%), Central America(1.00%), Western Europe(1.00%), Mid East(1.00%), Eastern Europe(1.00%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,MVR system,Lamella plate

4. why should you buy from us not from other suppliers?

Jiangsu Saideli is a National High-tech enterprises integrating scientific research, sales and manufacture of centrifugal machinery and drying machinery. Established in 1953, with 54 years experience.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

We are based in Jiangsu, China, start from 1992,sell to Domestic Market(78.00%),North America(5.00%), Southeast Asia(3.00%), South Asia(2.00%), South America(2.00%), Eastern Asia(2.00%), Oceania(1.00%), Africa(1.00%), Southern Europe(1.00%), Northern Europe(1.00%), Central America(1.00%), Western Europe(1.00%), Mid East(1.00%), Eastern Europe(1.00%). There are total about 1000+ people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Centrifuge,MVR system,Lamella plate

4. why should you buy from us not from other suppliers?

Jiangsu Saideli is a National High-tech enterprises integrating scientific research, sales and manufacture of centrifugal machinery and drying machinery. Established in 1953, with 54 years experience.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Hot Searches