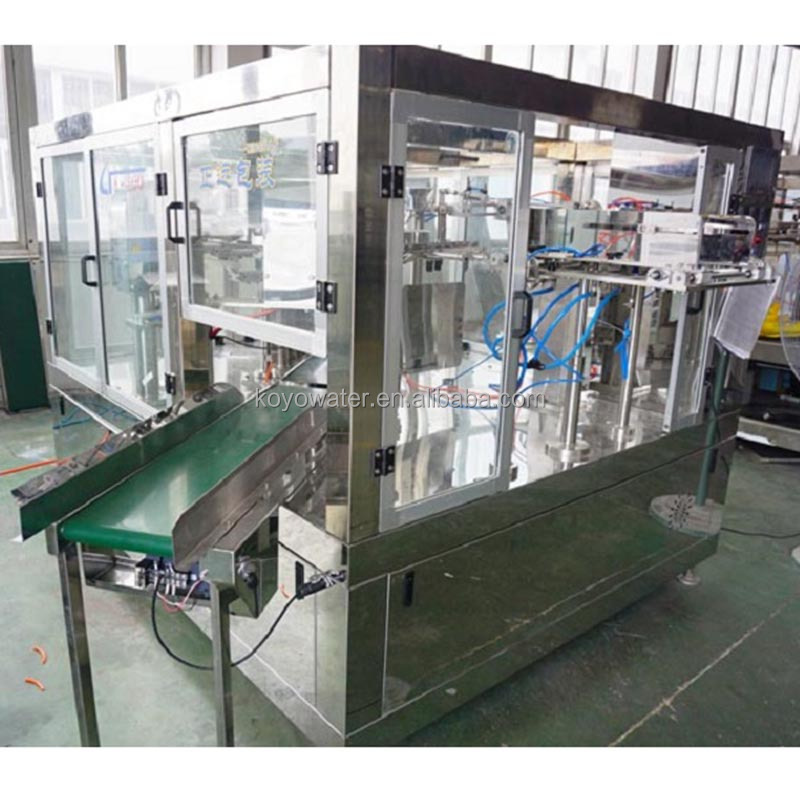

- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

35~55bag/min

-

Weight (KG):

-

1000

-

Voltage:

-

380V

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Koyo

-

Dimension(L*W*H):

-

1250x1050x1850mm

-

Style:

-

vertical type

-

function:

-

Automatic weigh,fill,seal,print,count

-

Film material:

-

laminated film&LDPE film

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

After Warranty Service3:

-

Spare parts

-

After Warranty Service4:

-

Field maintenance and repair service

-

Certification:

-

CE,ISO9001:2008

Quick Details

-

Function:

-

FILLING, Labeling, Laminating, Sealing, bag feeding,zipper opening, bag opening,filling,date printing,sealing,cooling,shaping

-

Packaging Type:

-

Stand-up Pouch, premade bags, doypack,ziplocked bag, flat bag, four side seal bag

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

35~55bag/min

-

Weight (KG):

-

1000

-

Voltage:

-

380V

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Koyo

-

Dimension(L*W*H):

-

1250x1050x1850mm

-

Style:

-

vertical type

-

function:

-

Automatic weigh,fill,seal,print,count

-

Film material:

-

laminated film&LDPE film

-

After Warranty Service1:

-

Video technical support

-

After Warranty Service2:

-

Online support

-

After Warranty Service3:

-

Spare parts

-

After Warranty Service4:

-

Field maintenance and repair service

-

Certification:

-

CE,ISO9001:2008

Introduction:

This packing unit consists of one premade bag packing machine for bagging ,one set combination weigher for weighing , one z type bucket elevator for feeding ,one platform for supporting weigher and one conveyor for taking off the finished bags .It integrates functions of automatic bag-making, weighing, filling, sealing, printing, punching, cutting and sealing into one. The advanced design has guaranteed this machine suits for irregular shape kinds of products,like chips,jelly,candy,vegetable,dried food, frozen food,dried fruits,etc. Its adjustment , operation and maintenance are very convenient.

Application

Detailed photos:

Advantages:

|

|

|

|

Combination weigher |

Adopt high precision and high accurate loadcell of famous brand, resolution is improved up to 2 decimal; |

|

Program recovery function can reduce operation failures and support multi-segment weight calibration; |

|

|

No products auto pause function can improve weighing stability and accuracy; |

|

|

Linear amplitude can be adjusted independently in the running; |

|

|

Many languages available for global markets. Mechanical Character |

|

|

Weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy; |

|

|

Aluminum thickened middle standing enhances the strength of the machine, making the time for stabilizing hoppers much shorter. |

|

|

Premade bag packing machine |

Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials. |

|

Safety device: Machine stop at abnormal air pressure, heater disconnection alarm |

|

|

With independent touch screen for seting parameters |

|

|

Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags. |

|

|

The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time. |

|

|

Use no oil vacuum pump, avoid polluting the environment in the production. |

|

|

The opening zipper framework is special in the feature of zipper bag,it can avoid distortion or destroy when open the zipper |

|

|

Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food |

Technical parameters:

|

Model |

Weigher/Filler |

Working station |

Bag type |

Bag size:(mm) |

Max speed |

|

KYG 6-200 |

ZH10 |

6 |

Pillow bag, 4 side/ 3 side seal bag,

|

W(80-200)*L(100-300) |

50BPM |

|

KYG 6-260 |

ZH10 |

6 |

W(130-260)*L(100-300) |

50BPM |

|

|

KYG 6-300 |

ZH14 |

6 |

W(180-300)*L(200-500) |

40BPM |

|

|

KYG 8-200 |

ZH10 |

8 |

Pillow bag, 4 side/ 3 side seal bag / Stand up bag with Zipper /doy bag |

W(80-200)*L(100-300) |

50BPM |

|

KYG 8-260 |

ZH10 |

8 |

W(130-260)*L(100-300) |

50BPM |

|

|

KYG 8-300 |

ZH14 |

8 |

W(180-300)*L(200-500) |

40BPM |

FAQ

|

1.Who we are? |

|

We are manufacturer of automatic weighing packing machines , located in Hefei city,Anhui province,China.We were founded in 1998, already engaged in this packaging field more than 20 years. |

|

2. What we are producing and selling? |

|

Our products mainly includes automatic vertical weighing packing machines,automatic vacuum packing machine,automatic filling line,automatic bulk packaging& palletizing line, automatic secondary packing line for baler bags in plastic bag / pp woven bag/carton and ancillary equipment. |

|

3.Do we have our own production R&D team? Yes,We have professional teams for machine design,drawing making,machine assembling and testing,we also have a professional service team who can go abroad to help customer install and test the machines,also giving training. |

|

4. Do we have experience in non-standard design? |

|

Yes, we have designed and made some non-standard design packaging lines for customers, such as the screw weigher for ice cubes, which greatly reduces the problem of ice agglomeration We designed and developed bag edge folding & sealing and bottom flatting device on packing machine to make more beautiful bag shapes.We developed a high speed continuous packaging machine for increasing the packaging speed to 100bags per min.We developed a lifting screw metering machine to solve the dust problem in the ultra fine powder packaging process,etc. |

|

5. What certifications have our products passed? |

|

Our products have passed ISO 9001:2008 and CE certificates. |

|

6. How to pack our machines? |

|

After the machine is cleaned up, it is wrapped with film first, and then packaged in a wooden export box. |

|

7. What after-sales service can we provide? |

|

7.1we can communicate with shipping agent and delivery machine for customer; 7.2we will offer customer the user manual,electrical diagram,installation video,etc. 7.3we will offer customer documents for clean custom,includes commercial invoice,packing list, bill of lading, certificate of origin,etc. 7.4 we will answer questions online from customer any time. 7.5we can send engineer to abroad for helping customer install & test machines and training. 7.6In the case of non-man-made damage, we will express the accessories free of charge and let the customer replace it. If it is deemed damaged, we only charge the cost price for the spare parts. |