- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RAINBOW

-

Voltage:

-

380V/415V/440V(Customized)

-

Dimension(L*W*H):

-

25m*2m*2.5m

-

Power (kW):

-

37

-

Weight:

-

12000 KG

-

Raw material:

-

PVC WPC

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

SCHNEIDER or SIEMENS Brand

-

Screw type:

-

single-screw Screw

-

Cooling way:

-

Recycling Water Cooling

-

Control:

-

Simens PLC+Touch Screen

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RAINBOW

-

Voltage:

-

380V/415V/440V(Customized)

-

Dimension(L*W*H):

-

25m*2m*2.5m

-

Power (kW):

-

37

-

Weight:

-

12000 KG

-

Raw material:

-

PVC WPC

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

SCHNEIDER or SIEMENS Brand

-

Screw type:

-

single-screw Screw

-

Cooling way:

-

Recycling Water Cooling

-

Control:

-

Simens PLC+Touch Screen

-

Marketing Type:

-

Hot Product 2022

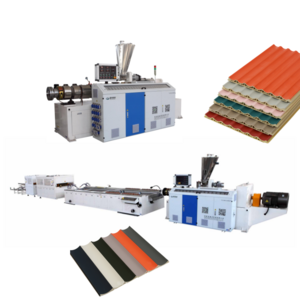

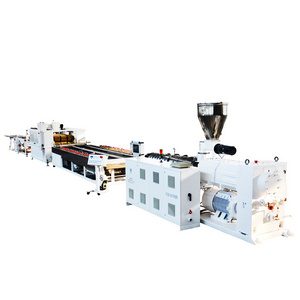

Product View

PVC WPC Decking Wall Panel Making Machine

The machine can pro

duce decorative wall panel, door frame, skirting board, etc. It consists of extruder, mould, calibrat

ing platform, tractor, cutter and stacker. The main materials are PVC & Wooden powder.

|

PVC WPC Decking Wall Panel Making Machine

|

|

|

||

|

1

|

SJ65/28 SINGLE SCREW EXTRUDER

|

1 SET

|

||

|

2

|

EXTRUSION MOULD

|

1 SET

|

||

|

3

|

FORMING MOLD

|

1 SET

|

||

|

4

|

VACUUM CALIBRATION COOLING PLATFORM

|

1 SET

|

||

|

5

|

HAUL OFF

|

1 SET

|

||

|

6

|

CUTTING MACHINE

|

1 SET

|

||

|

7

|

STACKER

|

1 SET

|

||

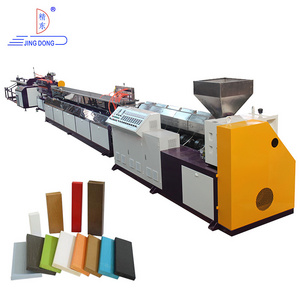

Details Images

Product Introduction

WPC Wall Panel is a

n ever incresingly popular choice for finishing the inside of commrecial and domestic building. Thi

s provides a hardwearing, protective layer against the elements and is an excellent insulator.

Water tank length:6m

water pump:3kw

vacuum pump:5.5kw*3sets

Water nozzle:48pcs ,material:brass

Power:1.5kw*2sets ,ABB frequency control

Haul off form:

Silicon Rubber caterpillar, Pneumatic control

Valid clamping length:2M

Power:3kw

Equipped with dust collection device

STACKER

Stacker length:6M

Stacker type:

Dismountable and reversible

ELECTRICAL PARTS

Products Application

Hot Recommed

Delivery

FAQ

Q1: Your company is a trading company or a machine manufacturer?

A1:Our company is a plastic machinery manufacturer which is engaged into this trade more than 15 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it's more convenient.

Q2: How to get an accurate offer?

A2: Because our offer and technical specification is associated with your final product and requested capacity,we will choose the right model of extruder and mould after understanding all the information,then we could supply our plan.We could fully exchange information by Email, whatsapp or wechat.

Q3: Where is your factory and which port is the nearest to your factory?

A3: My factory is in Qingdao city, Shandong Province and the nearest seaport is Qingdao port.

Q4: How long is the delivery time?

A4: Generally it will take 30-45 days.

Q5: Could you send your engineers to our factory?

A5: Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your factory.In addition,if you need our engineers available in the future,we also could send our engineers.

If you have any questions, please do not hesitate to contact us. We Look forward to listening to you!

A1:Our company is a plastic machinery manufacturer which is engaged into this trade more than 15 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it's more convenient.

Q2: How to get an accurate offer?

A2: Because our offer and technical specification is associated with your final product and requested capacity,we will choose the right model of extruder and mould after understanding all the information,then we could supply our plan.We could fully exchange information by Email, whatsapp or wechat.

Q3: Where is your factory and which port is the nearest to your factory?

A3: My factory is in Qingdao city, Shandong Province and the nearest seaport is Qingdao port.

Q4: How long is the delivery time?

A4: Generally it will take 30-45 days.

Q5: Could you send your engineers to our factory?

A5: Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your factory.In addition,if you need our engineers available in the future,we also could send our engineers.

If you have any questions, please do not hesitate to contact us. We Look forward to listening to you!

Hot Searches